Method for machining circular array grooves with electrode displacement compensation

A circular array, offset compensation technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high work intensity, high tooling cost, time-consuming and labor-intensive, etc., to expand the processing stroke, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

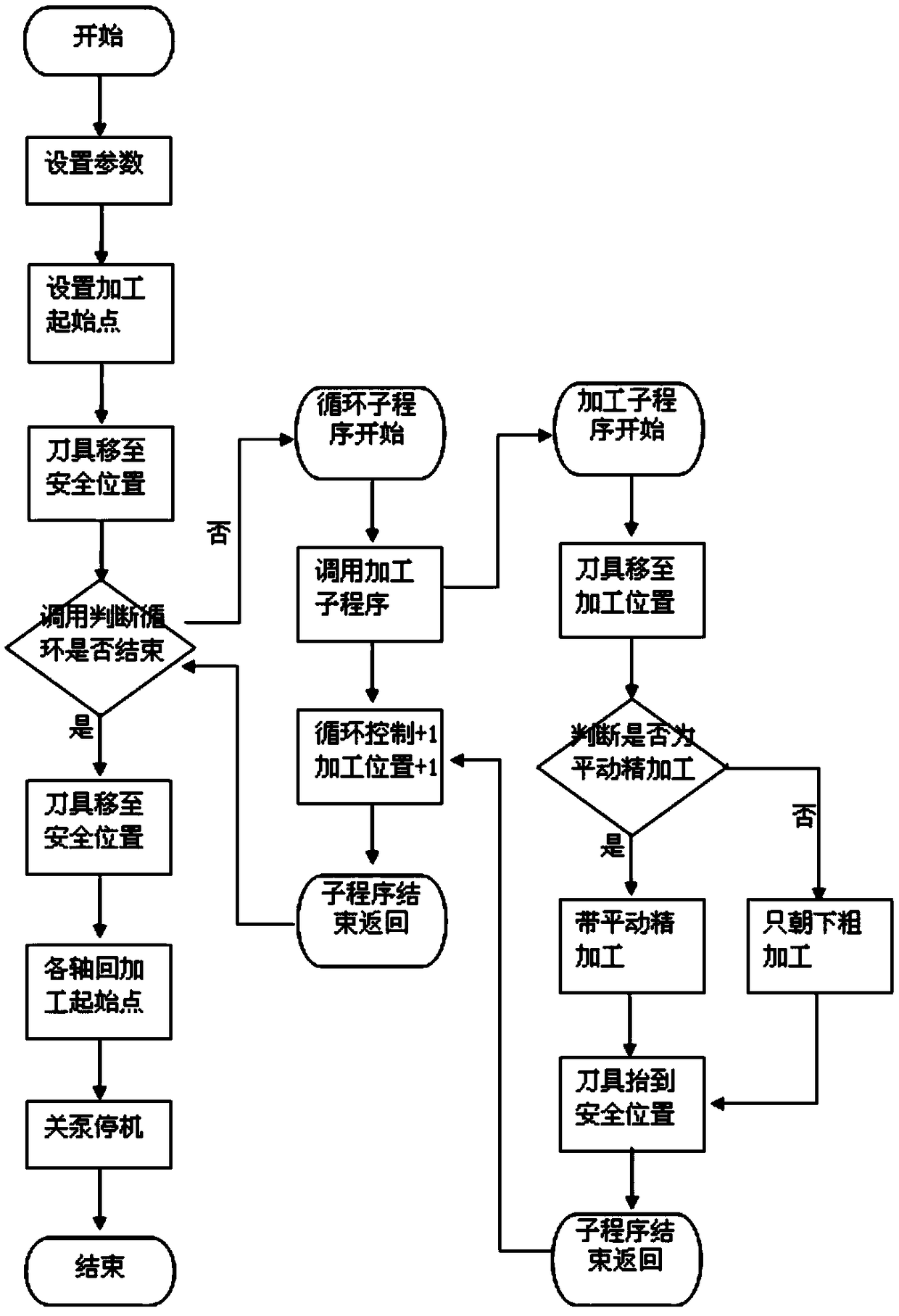

[0094] An aviation disk part needs to process 72 centripetal array square grooves on the circumference of Φ560mm, the angle of the first groove is 0°, the number is 1, and the order is incremented counterclockwise; the processing method is to start rough machining from the 21st groove to the 25th After the groove processing is completed, the processing depth is -5.0mm; then finish machining starts from the 5th groove to the 15th groove junction and ends, the processing depth is -8.0mm, and the translational radius is 0.1mm. Its processing steps are:

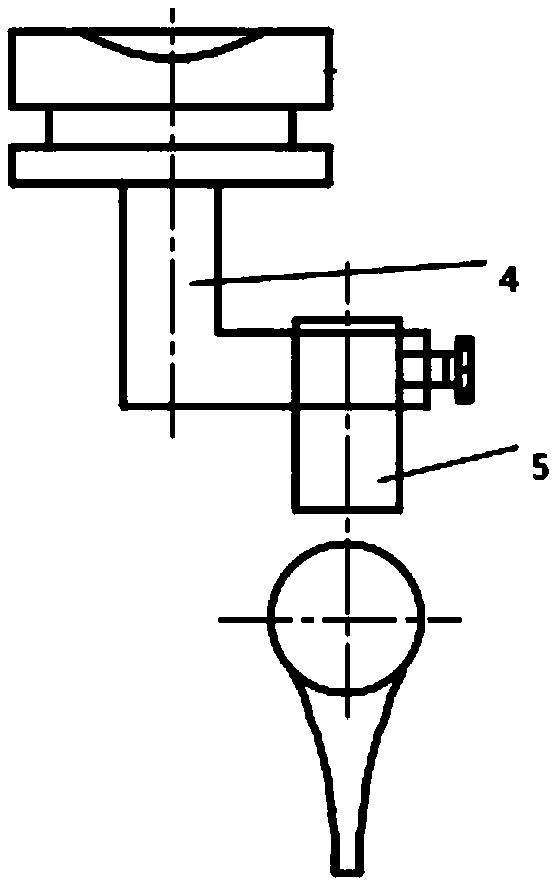

[0095] (1) Install the probe on the C-axis and the reference ball on the workbench, use the external centering function to make the probe and the reference ball coaxial, and set the X and Y coordinates of the machine tool to zero;

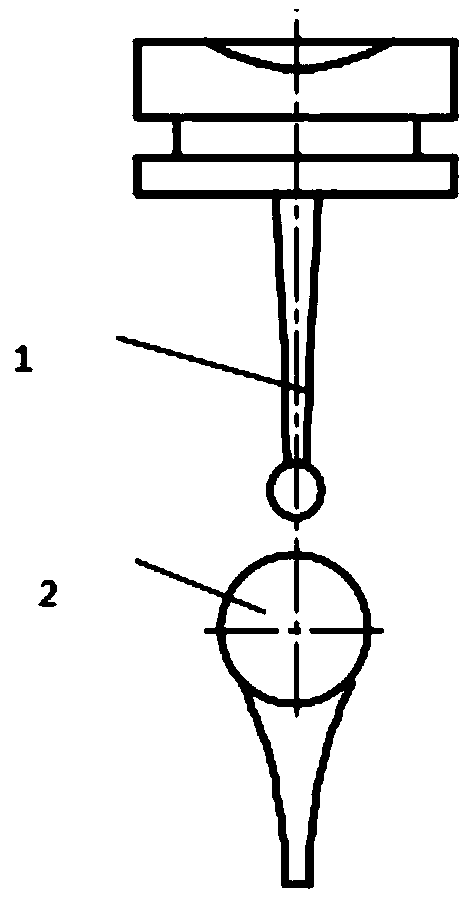

[0096] (2) Ensure that the reference ball is fixed, remove the probe, install the cantilever electrode holder and the electrode, use the external centering function to make the center of the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com