Defoaming and heat insulation biological fermentation tank

A bio-fermenter and defoaming technology, which is applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc. Protection, affecting the fermentation effect and other issues, to achieve the effect of facilitating later maintenance, ensuring temperature stability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

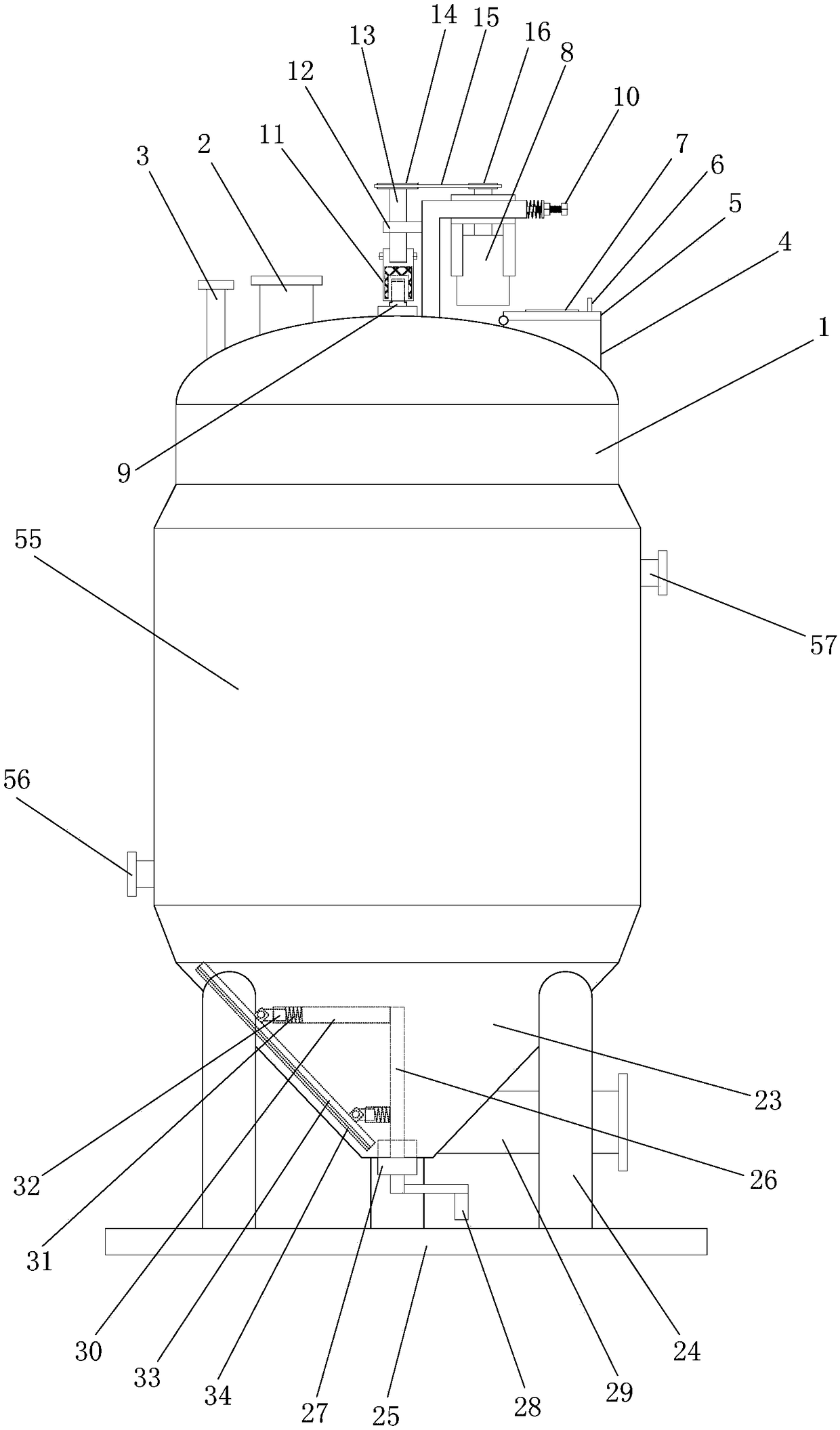

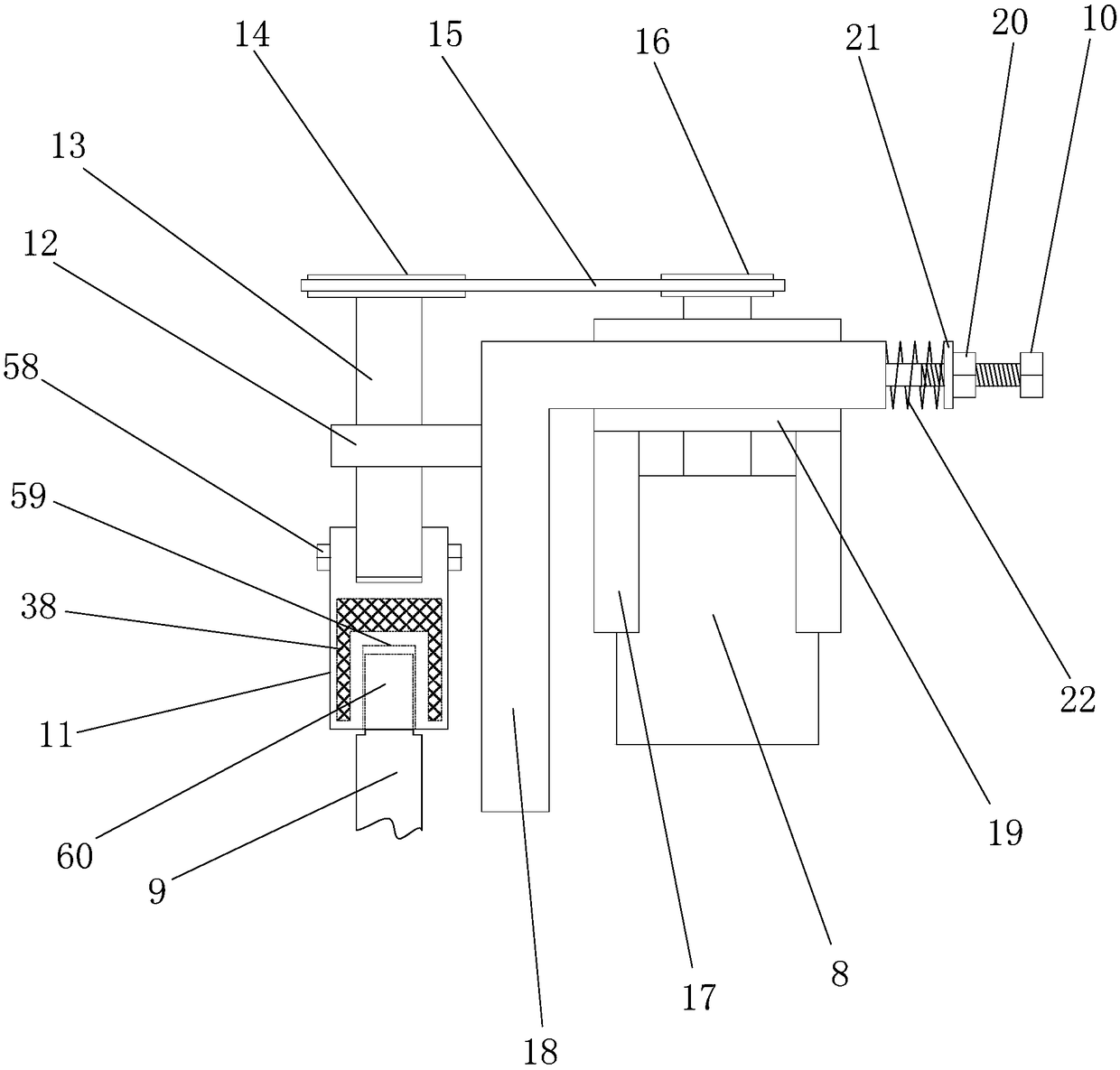

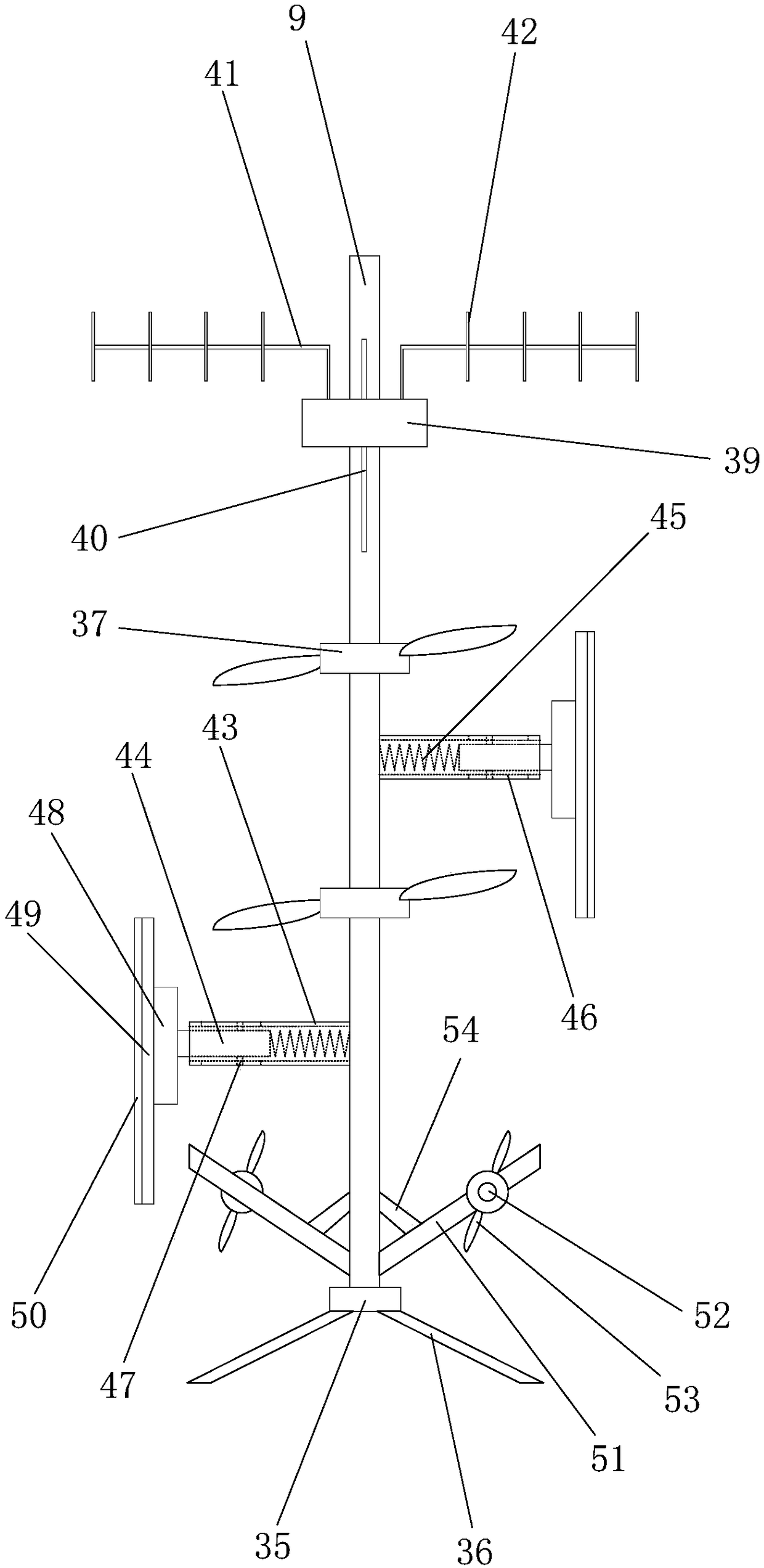

[0017] Such as Figure 1-3 As shown, the defoaming and heat-insulating biological fermentation tank disclosed by the present invention includes: a tank body 1, a stirring motor 8, a stirring shaft 9 and a jacket 55; the top of the tank body 1 is provided with a main material pipe 2 and an auxiliary material pipe 3 And the maintenance channel 4; a sealing cover 5 is hingedly installed at the upper opening of the maintenance channel 4, and a glass observation window 7 and a door handle 6 are arranged on the sealing cover 5; the bottom of the tank body 1 is set as an inverted conical bottom 23 ; On the outer conical surface of the inverted conical bottom 23, three supporting legs 24 are vertically arranged; the lower ends of the three supporting legs 24 are fixedly installed on the same circular base plate 25; Also be provided with a drainpipe 29 that communicates with the interior; At the center of the inverted conical bottom 23, a wall-scraping rotating shaft 26 is vertically r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com