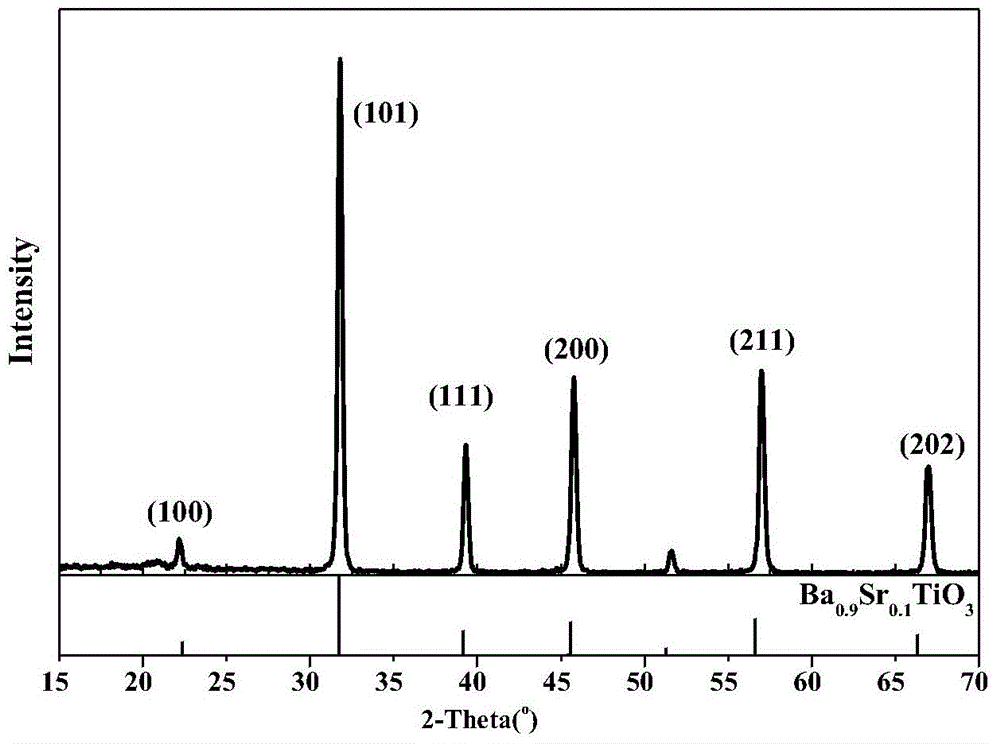

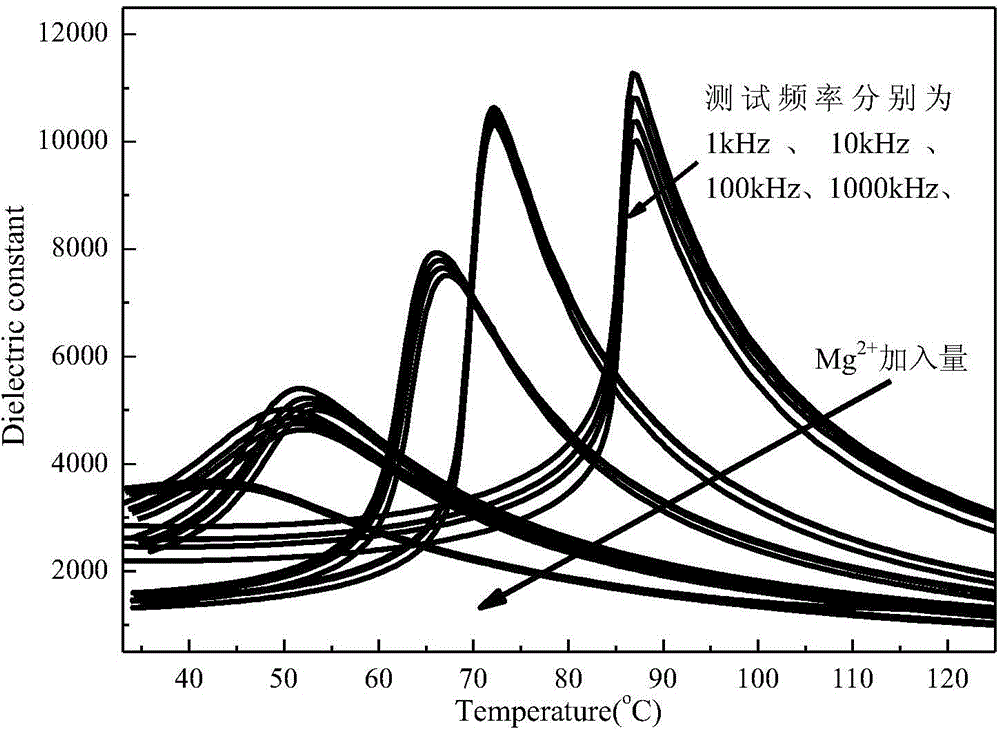

Preparation method of Ba(0.9-x)Sr0.1MgxTiO3 temperature-stable lead-free ceramic

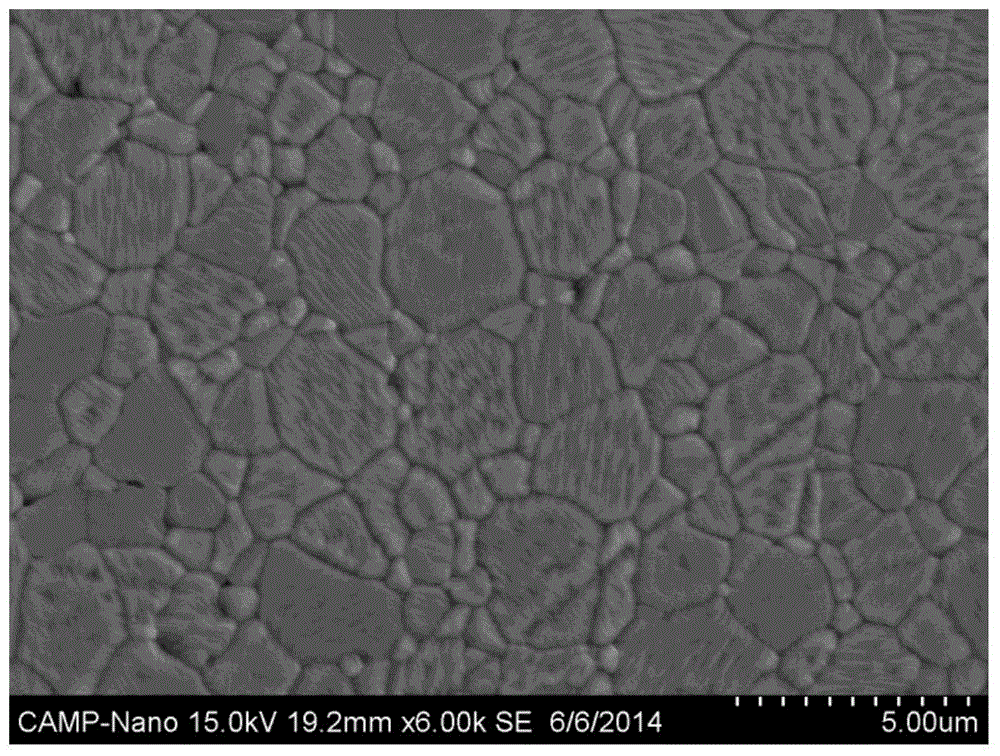

A temperature-stable, ceramic preparation technology, applied in the field of functional ceramics, can solve the problems of limited application range, poor temperature stability, and achieve the effect of ensuring temperature stability, high dielectric constant, and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: adding the first part of KOH solution with a concentration of 4mol / L to Sr(NO) with a concentration of 1.5mol / L 3 ) 2 solution mixed to obtain mixed solution A, in mixed solution A, Sr(NO 3 ) 2 : The molar ratio of KOH is 1:1.2; while TiCl 4 Add dropwise into the second KOH solution with a concentration of 5mol / L, and mix evenly to obtain a mixed solution B. In the mixed solution B, TiCl 4 : The molar ratio of KOH is 1:4; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:0.8, take mixed solution A and mixed solution B to mix, stir evenly to get SrTiO 3 precursor solution;

[0032] Step 2: TiCl 4 Add BaCl dropwise 2 Mix well in the solution, in which BaCl 2 and TiCl 4 The molar ratio is 1:0.6, to obtain a mixed solution C; then KOH is added to the mixed solution C, wherein BaCl 2 The molar ratio with KOH is 1:5 to get BaTiO 3 precursor solution;

[0033] Step 3: the SrTiO prepared in step 1 3 Precursor solution and BaTiO produced in step 2 3 ...

Embodiment 2

[0036] Step 1: adding the first part of KOH solution with a concentration of 4.9mol / L into Sr(NO 3 ) 2 solution mixed to obtain mixed solution A, in mixed solution A, Sr(NO 3 ) 2 : The molar ratio of KOH is 1:1.4; while TiCl 4 Add dropwise the second part of KOH solution with a concentration of 4.9mol / L, and mix well to obtain a mixed solution B. In the mixed solution B, TiCl 4 : The molar ratio of KOH is 1:3.5; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:0.9, take mixed solution A and mixed solution B to mix, stir evenly to get SrTiO 3 precursor solution;

[0037] Step 2: TiCl 4 Add BaCl dropwise 2 Mix well in the solution, in which BaCl 2 and TiCl 4 The molar ratio of is 1:0.7, obtains mixed solution C; Then KOH is added in mixed solution C, wherein BaCl 2 The molar ratio with KOH is 1:6 to get BaTiO 3 precursor solution;

[0038] Step 3: the SrTiO prepared in step 1 3 Precursor solution and BaTiO produced in step 2 3 Mix the precursor solution, st...

Embodiment 3

[0041] Step 1: adding the first part of KOH solution with a concentration of 4.2mol / L into Sr(NO 3 ) 2 solution mixed to obtain mixed solution A, in mixed solution A, Sr(NO 3 ) 2 : The molar ratio of KOH is 1:1; while TiCl 4 Add dropwise into the second part of KOH solution with a concentration of 4.5mol / L, and mix evenly to obtain a mixed solution B. In the mixed solution B, TiCl 4 : The molar ratio of KOH is 1:3; then press Sr(NO 3 ) 2 and TiCl 4 The molar ratio is 1:1.1, take mixed solution A and mixed solution B to mix, stir evenly to get SrTiO 3 Precursor solution;

[0042] Step 2: TiCl 4 Add BaCl dropwise 2 Mix well in the solution, in which BaCl 2 and TiCl 4 The molar ratio is 1:0.8, to obtain a mixed solution C; then KOH is added to the mixed solution C, wherein BaCl 2 The molar ratio with KOH is 1:7 to get BaTiO 3 Precursor solution;

[0043] Step 3: the SrTiO prepared in step 1 3 Precursor solution and BaTiO produced in step 2 3 Mix the precursor solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com