Low-temperature sintering temperature stabilization type zirconate microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and temperature-stable technology, which is applied in the field of electronic information materials and devices, can solve the problems of high performance and low-temperature sintering, and achieve the effects of low cost, abundant raw material sources, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

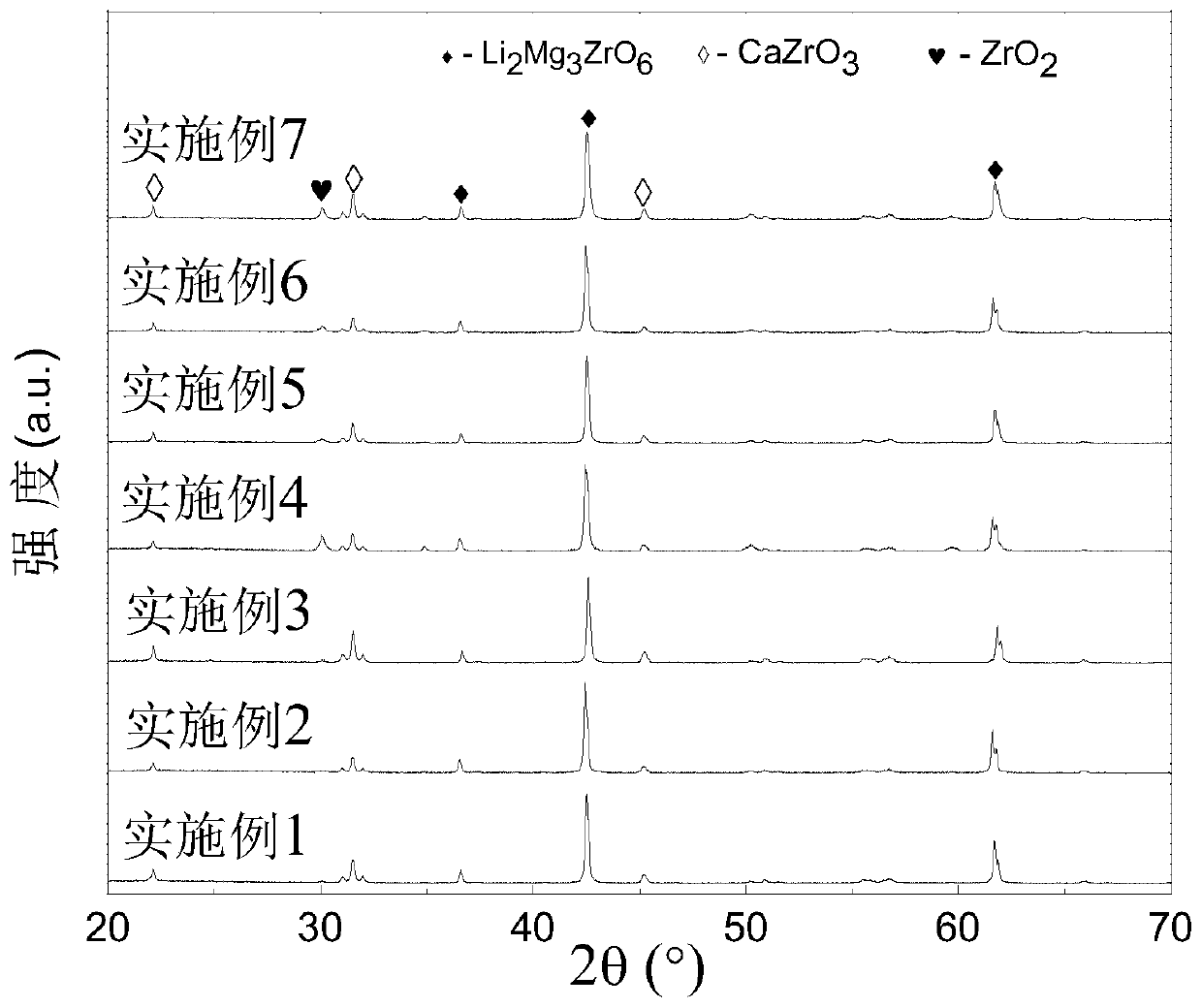

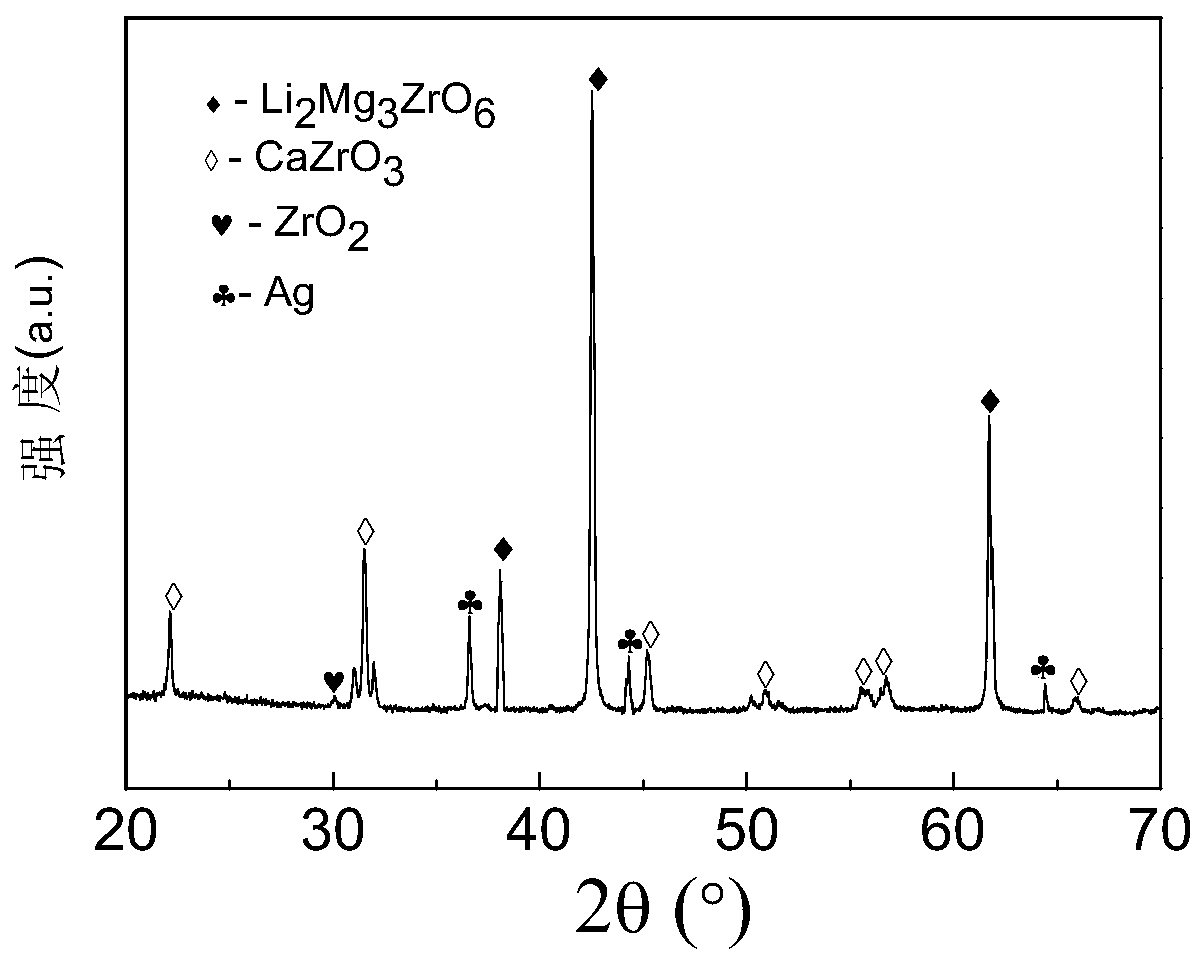

Embodiment 1

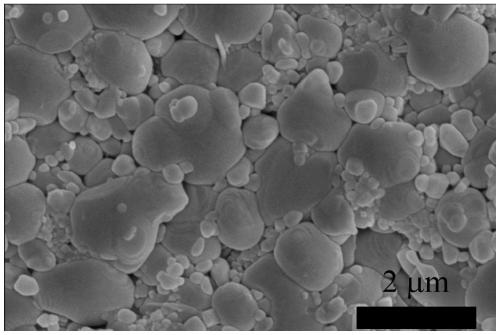

[0033] (1) Preparation of Li 2 Mg 3 ZrO 6 Burnt powder

[0034] Press Li 2 Mg 3 ZrO 6 The stoichiometric ratio weighs 4.413g of MgO with a purity of 99.99%, and 2.752g of Li with a purity of 98%. 2 CO 3 and 4.498 g of ZrO with a purity of 99.99% 212g:25g:25ml of raw materials, agate balls, and absolute ethanol are put into a nylon ball mill jar according to the mass volume ratio, fully mixed and ball milled for 8 hours, dried at 90°C for 10 hours, and pre-calcined at 1200°C for 5 hours to prepare Li 2 Mg 3 ZrO 6 Pre-burned powder;

[0035] (2) Preparation of CaTiO 3 Burnt powder

[0036] by CaTiO 3 The stoichiometric ratio weighs 7.370g of CaCO with a purity of 99.9%. 3 and 5.876g of TiO with a purity of 99.99% 2 , put the raw materials, agate balls, and absolute ethanol in a mass volume ratio of 13g:30g:30ml into a nylon ball mill jar, mix and ball mill for 8 hours, dry at 90°C for 10 hours, and pre-calcine at 1000°C for 8 hours to prepare CaTiO 3 Pre-burned p...

Embodiment 2

[0041] (1) Preparation of Li 2 Mg 3 ZrO 6 Burnt powder

[0042] Press Li 2 Mg 3 ZrO 6 The stoichiometric ratio weighs 4.413g of MgO with a purity of 99.99%, and 2.752g of Li with a purity of 98%. 2 CO 3 and 4.498 g of ZrO with a purity of 99.99% 2 12g:30g:30ml of raw materials, agate balls, and absolute ethanol are put into a nylon ball mill jar according to the mass volume ratio, fully mixed and ball milled for 10 hours, dried at 100°C for 12 hours, and pre-calcined at 1200°C for 6 hours to prepare Li 2 Mg 3 ZrO 6 Pre-burned powder;

[0043] (2) Preparation of CaTiO 3 Burnt powder

[0044] by CaTiO 3 The stoichiometric ratio weighs 7.370g of CaCO with a purity of 99.9%. 3 and 5.876g of TiO with a purity of 99.99% 2 , put raw materials, agate balls, and absolute ethanol in a mass volume ratio of 13g:35g:35ml into a nylon ball mill jar, mix and ball mill for 10 hours, dry at 100°C for 12 hours, and pre-calcine at 1000°C for 10 hours to prepare CaTiO 3 Pre-burned...

Embodiment 3

[0048] (1) Preparation of Li 2 Mg 3 ZrO 6 Burnt powder

[0049] Press Li 2 Mg 3 ZrO 6 The stoichiometric ratio weighs 4.413g of MgO with a purity of 99.99%, and 2.752g of Li with a purity of 98%. 2 CO 3 and 4.498 g of ZrO with a purity of 99.99% 2 , put raw materials, agate balls, and absolute ethanol in a mass volume ratio of 12g:20g:20ml into a nylon ball mill jar, fully mix and ball mill for 6 hours, dry at 80°C for 8 hours, and pre-calcine at 1200°C for 4 hours to prepare Li 2 Mg 3 ZrO 6 Pre-burned powder;

[0050] (2) Preparation of CaTiO 3 Burnt powder

[0051] by CaTiO 3 The stoichiometric ratio weighs 7.370g of CaCO with a purity of 99.9%. 3 and 5.876g of TiO with a purity of 99.99% 2 , put raw materials, agate balls, and absolute ethanol in a mass-volume ratio of 13g:25g:25ml into a nylon ball mill jar, mix well and ball mill for 6 hours, dry at 80°C for 8 hours, and pre-calcine at 1000°C for 6 hours to prepare CaTiO 3 Pre-burned powder;

[0052] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com