Spot welding-based welding spot strength detection mechanism

A spot welding strength and detection hole technology, which is applied in the strength detection of plate spot welding and the strength detection mechanism of solder joints, can solve the problems of invisible solder joints, failure, and unknown welding conditions, etc., and achieve simple and intuitive detection results. High detection rate, solving the effect of invisible solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

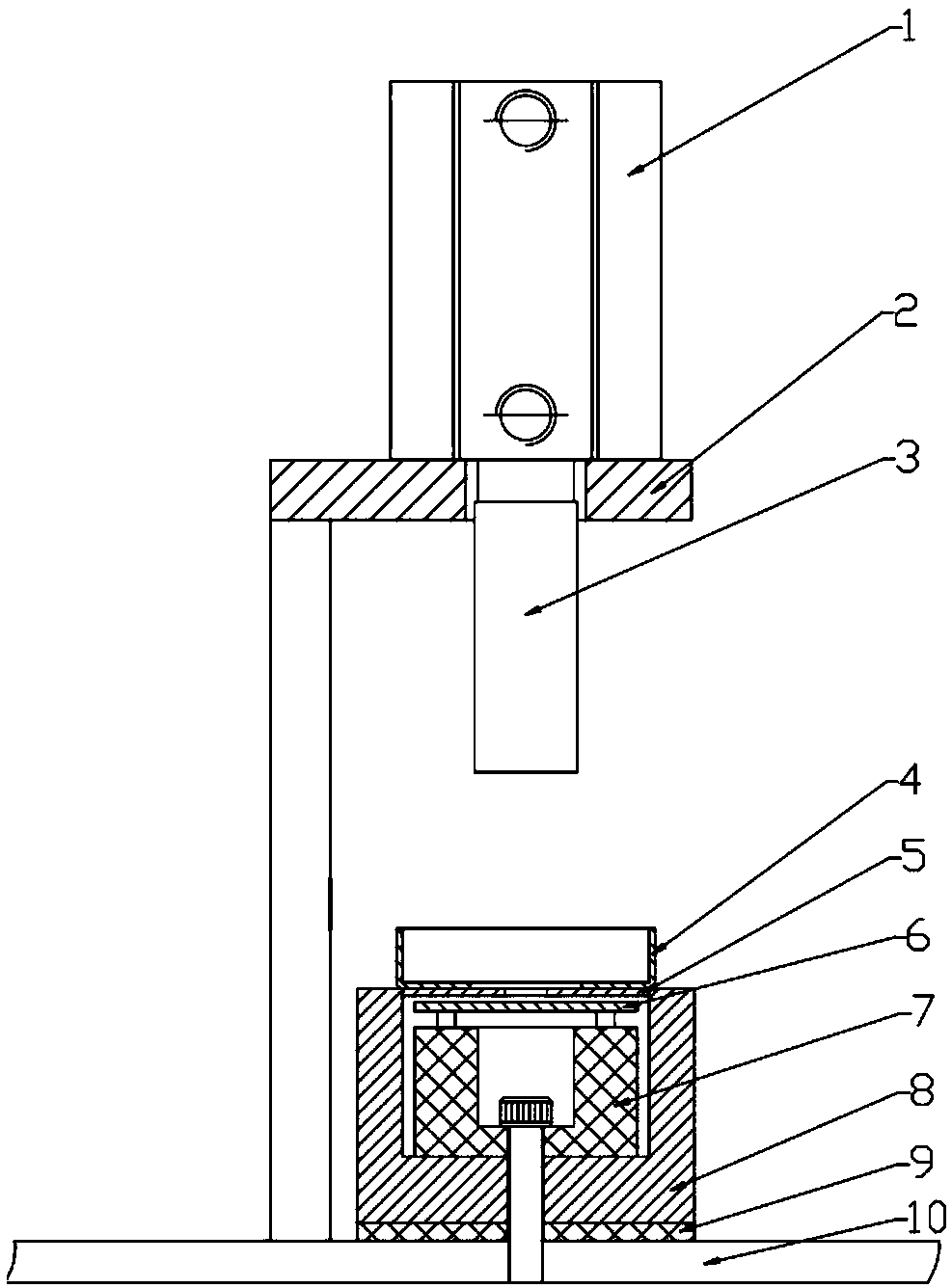

[0020] like figure 1 As shown, a spot welding strength detection mechanism provided by the present invention includes a detection table 10, the cylinder 1 is fixedly installed on the detection table 10 through the cylinder bracket 2, and the push rod and the pressure head 3 at the lower end of the cylinder 1 are threaded. connection, and different shapes and lengths of indenters can be replaced according to requirements. A detection base 8 fixed on the detection table 10 is provided under the cylinder 1, and an insulation is provided between the bottom surface of the detection base 8 and the detection table. Layer two 9, the detection base 8 is an upward opening, the detection base 8 is provided with an insulating layer 7, and the positive electrode sheet 6 is installed on the top of the insulating layer 7 by screws, and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com