Process for preparing silane by magnesium silicide method

A technology of magnesium silicide and silane, which is applied in the field of improved process for preparing silane, can solve problems such as high labor intensity, environmental pollution, and poor safety, and achieve the effects of increasing production capacity, reducing production costs, and stabilizing silane gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

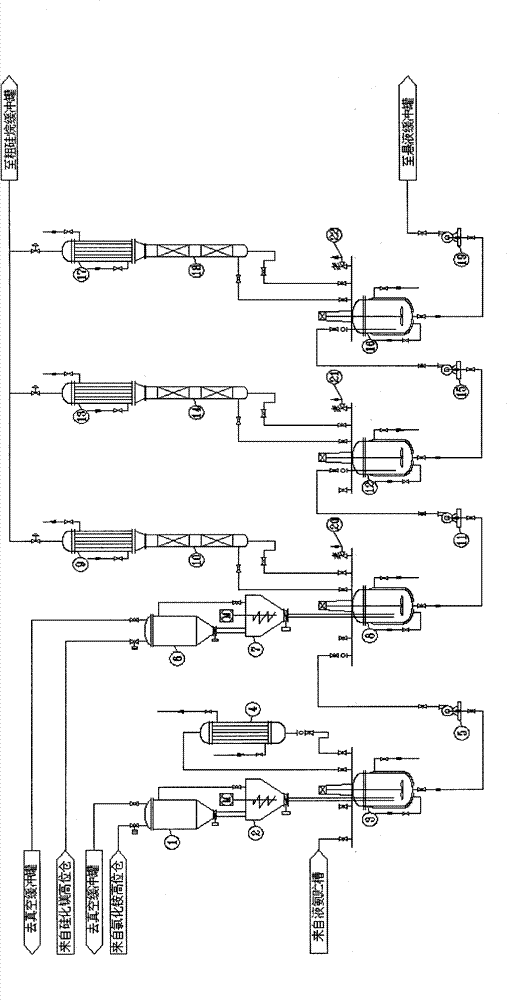

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of 3-stage silane generators in series and continuous silane

[0032] Before silane occurs, the entire reaction system is replaced with nitrogen to replace the oxygen in the reaction system;

[0033] After the oxygen replacement is completed, 80 parts per hour of liquid ammonia is injected from the buffer tank into the batching kettle 3, the vaporized ammonia is condensed by the condenser 4 and then returned to the batching kettle 3, and the ammonium chloride is passed through the high level tank 1 at 20 parts per hour. Screw feeder 2 adds in batching kettle 3, is mixed with 20% ammonium chloride liquid ammonia solution;

[0034] Ammonium chloride liquefied ammonia solution prepared is input first-stage silane generator 8 with 100 parts per hour through pump 5, simultaneously with the magnesium silicide in the magnesium silicide header tank 6 with 6.9 parts per hour (magnesium silicide and ammonium chloride) The molar ratio is 1: 4.1), and the mag...

Embodiment 2

[0039] Technological process is the same as embodiment 1, just changes 106.7 parts (being mixed with 15% ammonium chloride liquefied ammonia solution) into 106.7 parts (being mixed with 15% ammonium chloride liquid ammonia solution) of liquefied ammonia per hour add-on in embodiment 1, other conditions are constant. The yield of final product silane relative to magnesium silicide is 92.6%.

Embodiment 3

[0041] Technological process is the same as embodiment 1, just changes the per hour add-on of liquid ammonia into 64 parts (being mixed with 25% ammonium chloride liquid ammonia solution) by 80 parts in the embodiment 1, other conditions are constant. The yield of final product silane relative to magnesium silicide is 95.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com