High-precision loading device and a loading method thereof for placing an instrument in a cabin

A filling equipment and high-precision technology, which is applied in space navigation equipment, space navigation equipment, aircraft, etc., can solve problems such as poor versatility, low work efficiency, and damage to instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] First of all, it needs to be explained that the orientation words such as up, down, front, back, left, and right in the present invention are only described according to the accompanying drawings, so as to facilitate understanding, and are not intended to limit the technical solution and scope of protection of the present invention. .

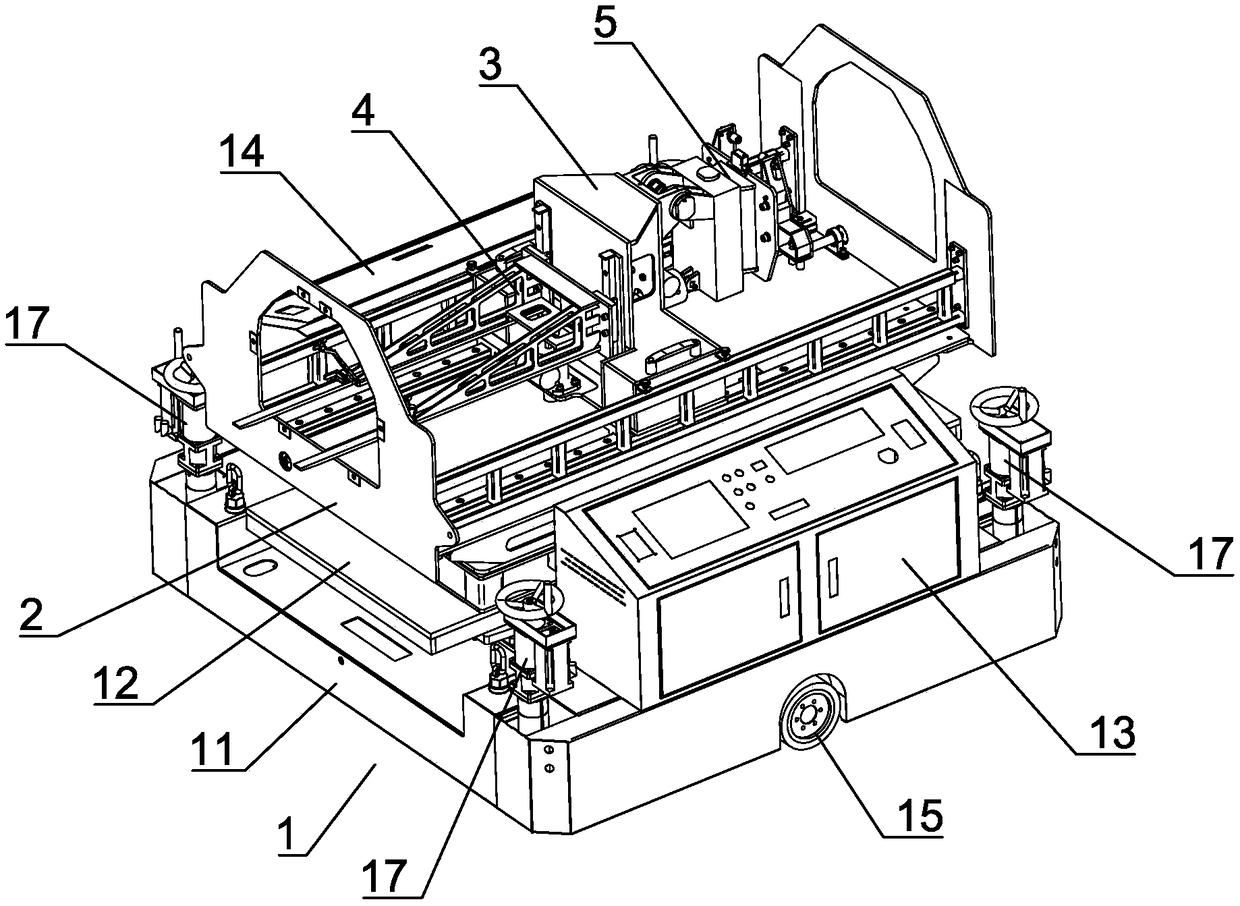

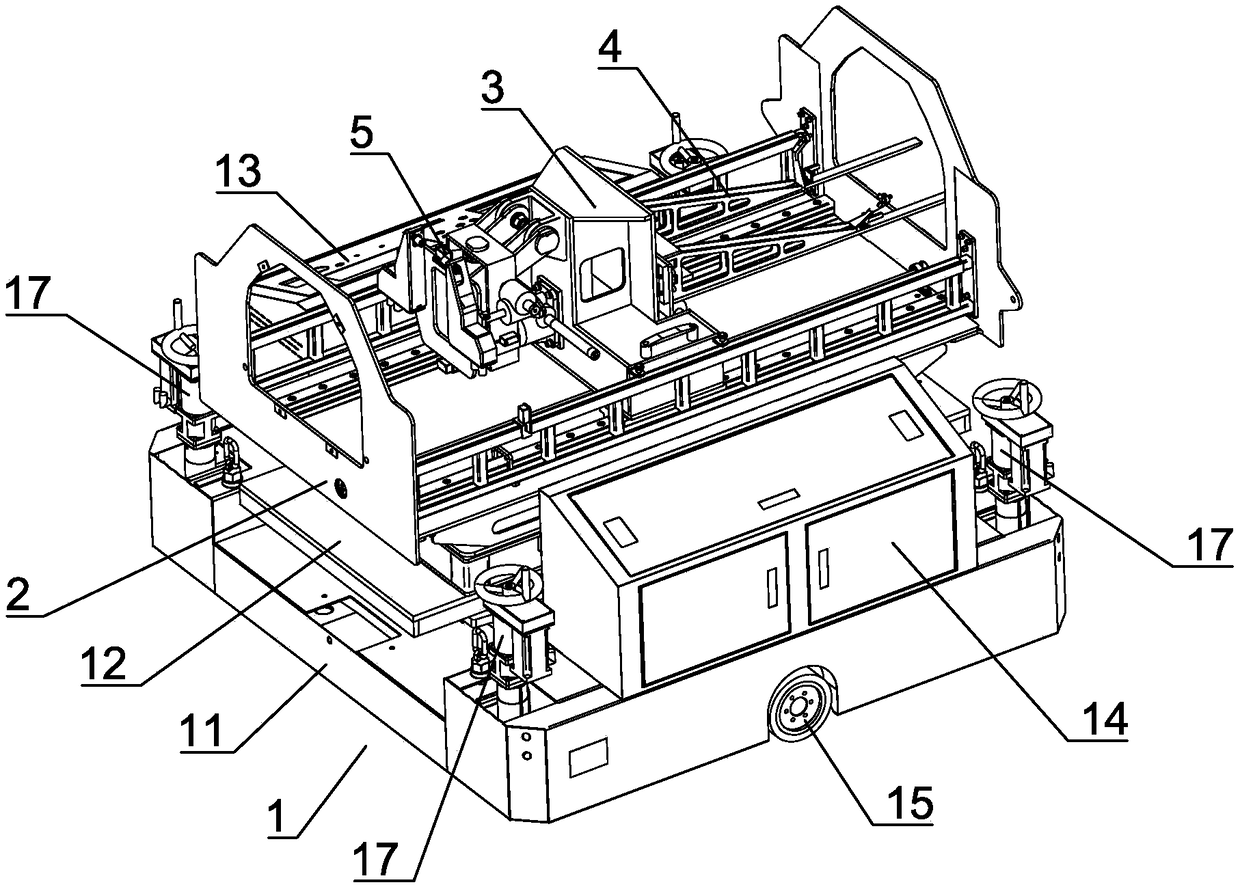

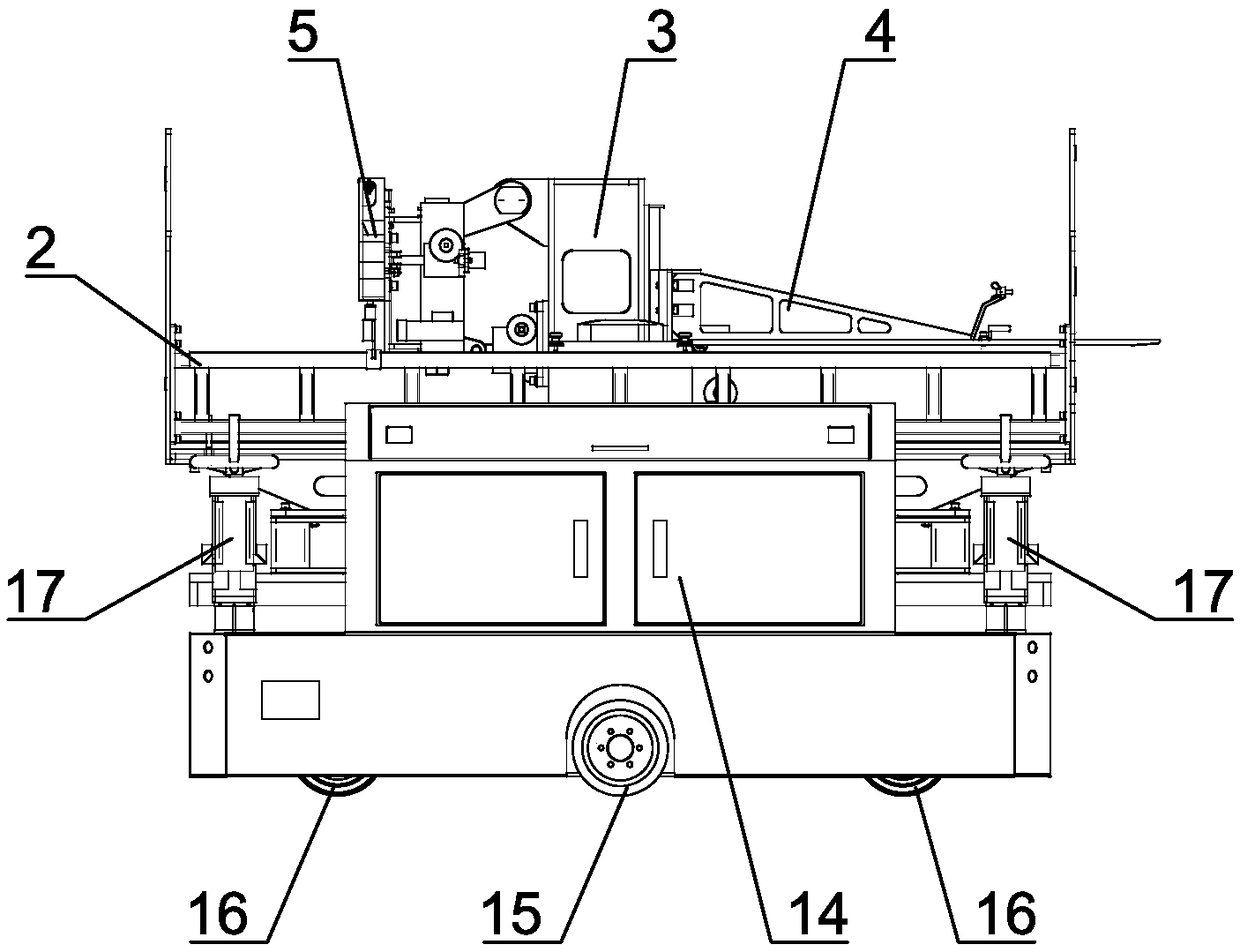

[0047] Such as Figure 1 to Figure 6 Shown is a specific embodiment of a high-precision filling device that places instruments in the cabin of the present invention, including a six-degree-of-freedom support platform 1 , a support frame 2 , a propulsion device 3 , a front loading clamp 4 and a rear loading clamp 5 . The six-degree-of-freedom support platform 1 specifically includes an underframe 11 and a rotary support platform 12 installed on the underframe 11 through a set of horizontal and vertical guide rails (not shown in the figure), and the underframe 11 is correspondingly arranged on the left and right sides of the rotary support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com