Screw joint type paper tape filtering machine

A filter, screw-on technology, applied in the direction of filtration and separation, moving filter element filters, separation methods, etc., can solve the problem of insufficient chain network operation accuracy and stability, the impact of the operator's health, and filter filtration. problems such as poor effects, to avoid adverse effects, shorten production cycles, and reduce the probability of occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

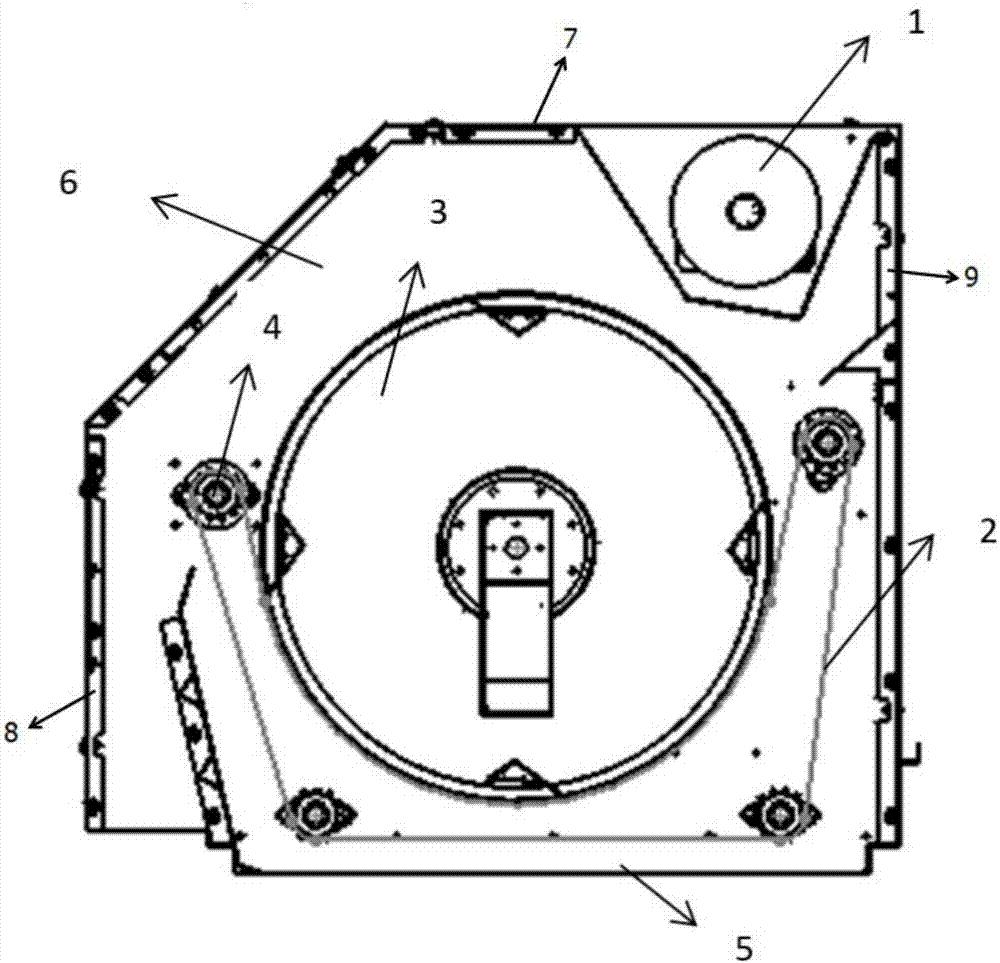

[0021] Example 1, such as Figure 1-3 Shown:

[0022] A screw-connected drum type paper belt 1 filter, the main body of the filter includes a front wall 8, a rear wall 9, a top cover 7, a wheel 3 and side plates 6 symmetrically arranged on both sides of the filter main body; The enclosed drum filter inner cavity is formed by bolt connection among the above-mentioned coaming plate, rear coaming plate 9, top cover 7, wheel disc 3 and side plate 6; In the isolation cavity, a wheel disc 3 is arranged on the lower left side of the isolation cavity, and several axles 4 are symmetrically arranged on both sides of the wheel disc 3, and a sprocket wheel is arranged on the wheel axle 4, and a chain net 2 is matched on the sprocket wheel; the chain net 2 forms a closed loop Transmission mechanism, the middle section of the chain net 2 is located below the wheel disc 3; the outer end of the paper tape 1 extends outward, and the extended section of the paper band 1 passes through the gap ...

Embodiment 2

[0032] Example 2, such as Figure 1-3 Shown:

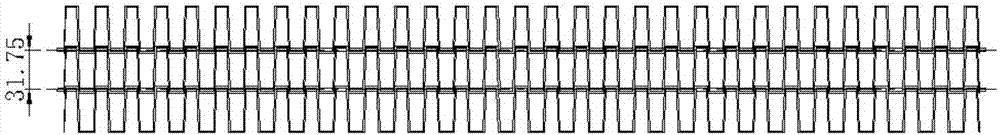

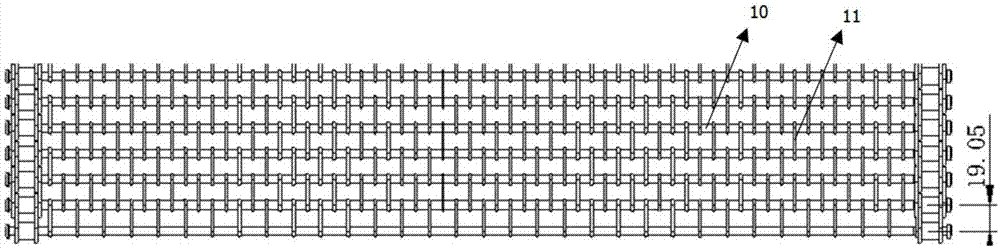

[0033] The side plate 6 is cut with a 6mm hot plate as a whole, without bending or welding, to ensure the flatness of the sprocket installation surface. During the cutting process, the laser scribing of the sprocket installation position ensures that the sprocket installation point meets the design requirements. The running track of the chain network is more accurate, and the running process is more stable.

[0034]The main structure of the screw-connected drum-type paper belt filter adopts the bolt installation process. Except for the edge of the wheel 3, which needs to be fully welded, the rest of the parts are connected by bolts to reduce the probability of occupational diseases caused by long-term welding operations. , while improving the working environment and improving work efficiency.

[0035] After the laser blanking of the screw-joint drum type paper filter machine, except the wheel 3 needs to be welded, the rest of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com