Online measuring tool and measuring method for high temperature gas cooled reactor heat transfer unit internal cylinder component outer circle finish turning

A technology of high-temperature gas-cooled stacks and heat exchange units, which is applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., and can solve the problems of surface roughness, tool durability, shape, dimensional accuracy, and high user requirements. problems, to achieve simple structure, improve quality and processing efficiency, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

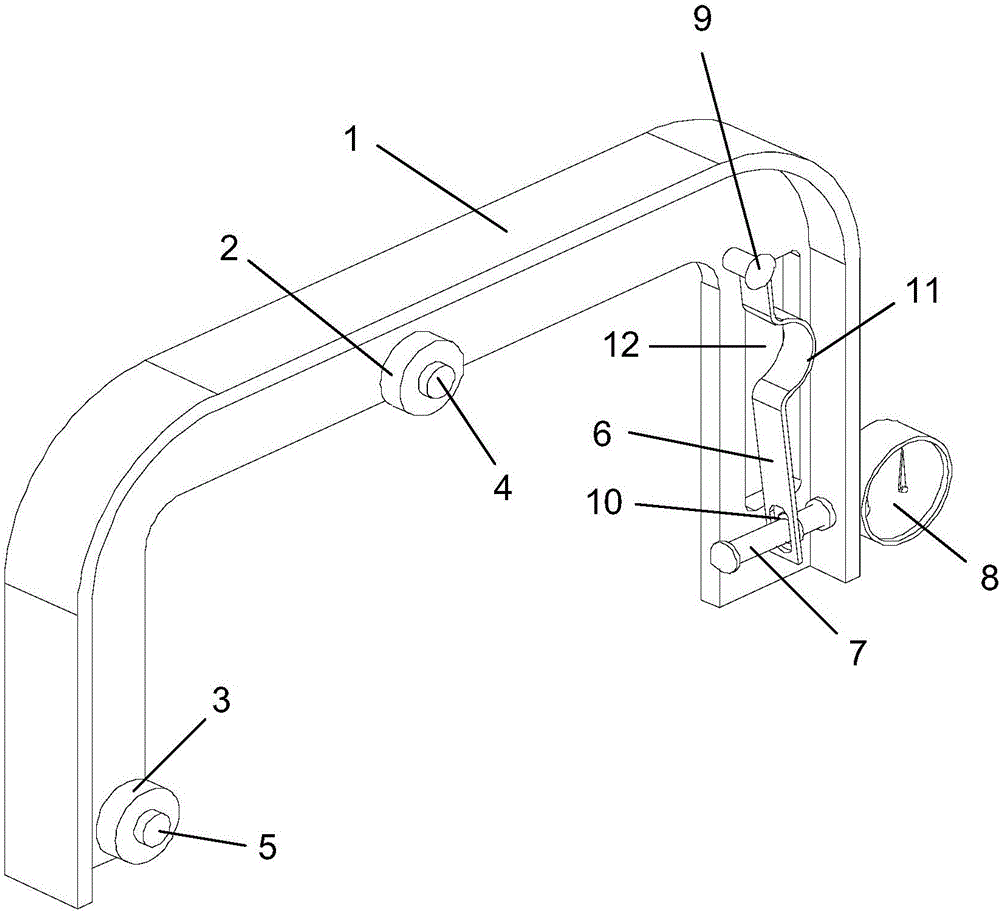

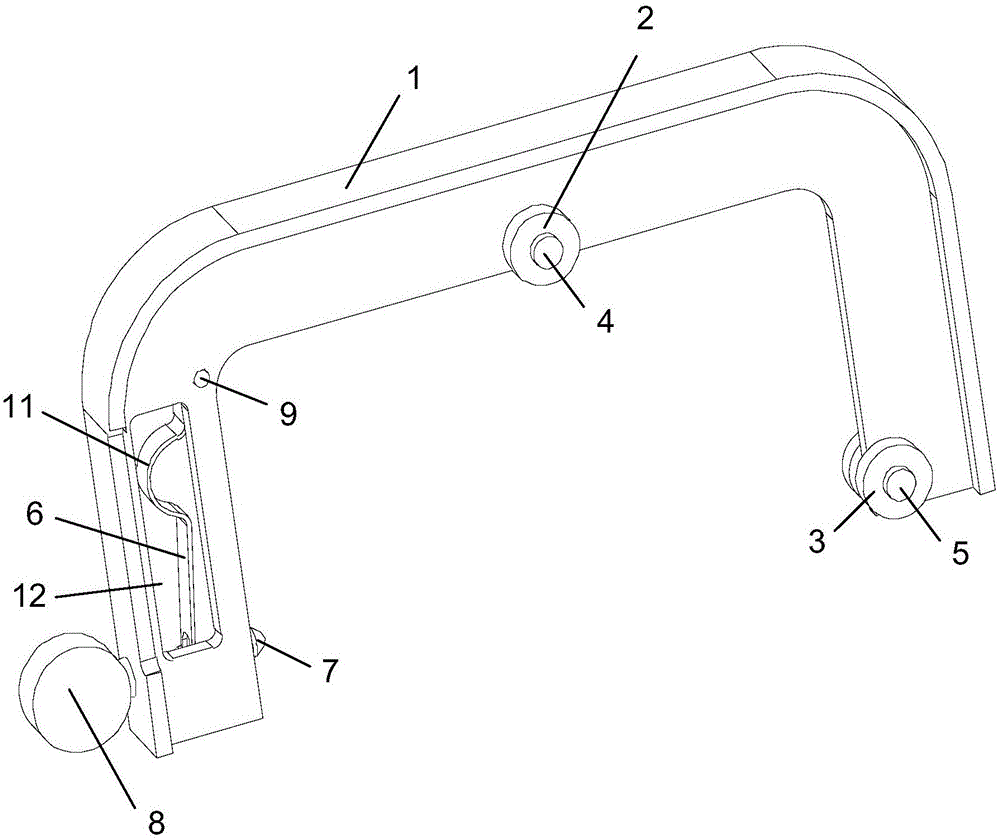

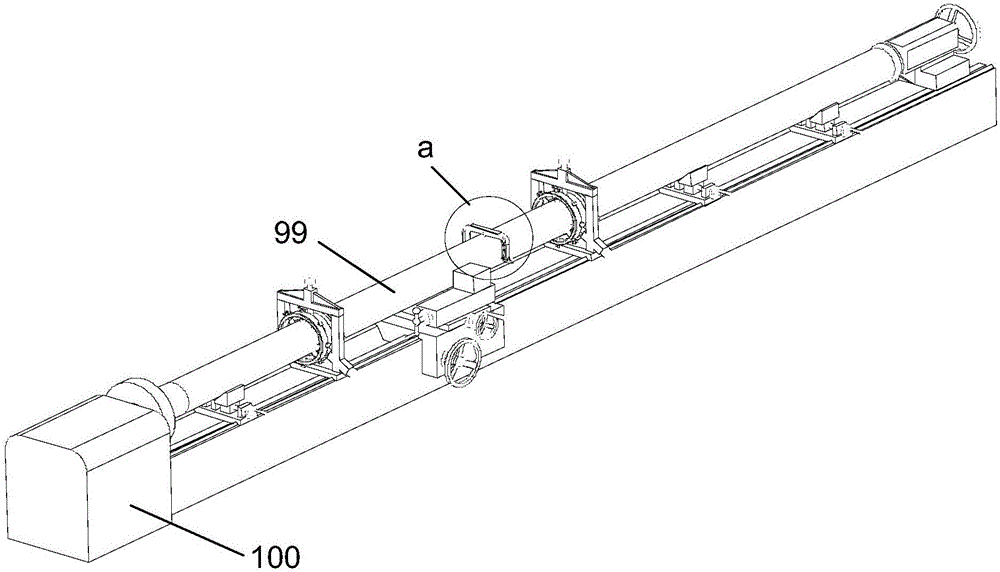

[0026] combine Figure 1 to Figure 2 As shown, the high-temperature gas-cooled reactor heat exchange unit inner cylinder assembly outer finishing online measuring tool provided by the present invention includes a bracket 1, a pair of upper rollers 2, a pair of side rollers 3 and a measuring mechanism. The bracket 1 is C-shaped and has an opening Set downwards, a pair of upper rollers 2 are respectively connected to both sides of the upper end of the bracket 1 through a roller shaft 4, a pair of side rollers 3 are respectively connected to both sides of one end of the bracket 1 through another roller shaft 5, and the measuring mechanism is set on the bracket At the other end of 1, the measuring mechanism includes a driving rod 6, a measuring head 7 and a dial indicator 8. The driving rod 6 is arranged longitudinally, and its up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com