Holographic real-time measuring method and device for measuring particle size of moving particle

A particle size, real-time measurement technology, applied in the direction of measuring devices, particle and sedimentation analysis, particle size analysis, etc., can solve the problem that the holographic measurement method of particle size cannot measure real-time in real time, so as to improve the reconstruction efficiency and increase the measurement error, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

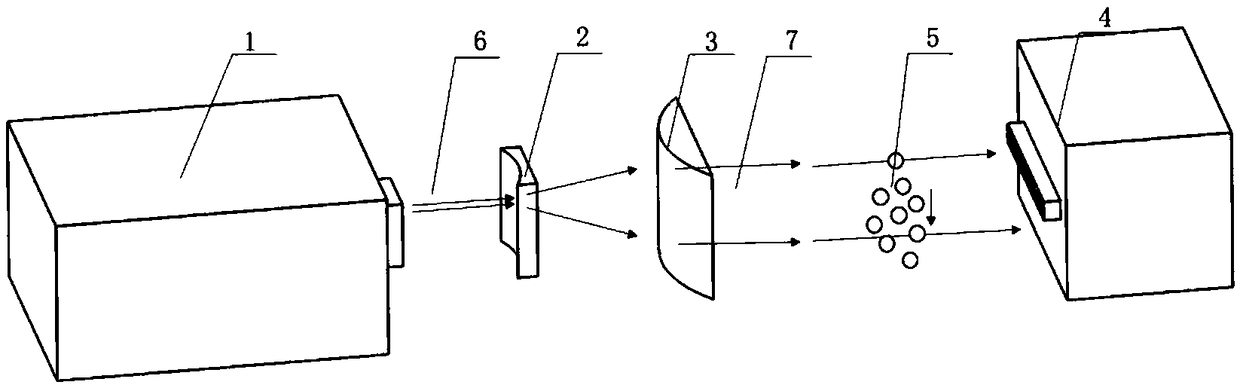

[0043] Such as figure 1 In the holographic real-time measurement device shown, the laser light source 1, the plano-concave cylindrical lens A 2, the plano-convex cylindrical lens B3, and the line array camera 4 are located on the same axis in the order of arrangement, which is a coaxial holographic form. The focal point of the plano-concave cylindrical lens A 2 coincides with the plano-convex cylindrical lens B 3 .

[0044]Specifically, in this embodiment, the laser light source 1 is a semiconductor continuous laser with a wavelength of 532 nanometers. The focal length of the plano-concave cylindrical lens A 2 is 30 mm, the length is 20 mm, and the width is 10 mm; the focal length of the plano-convex cylindrical lens B 3 is 60 mm, the length is 40 mm, and the width is 25 mm. The pixel size of the line scan camera 4 is 10 microns, the number of pixels is 4096×1, the effective measurement area of the line scan camera 4 can reach 4 cm, and the sampling frequency can reach 52 k...

Embodiment 2

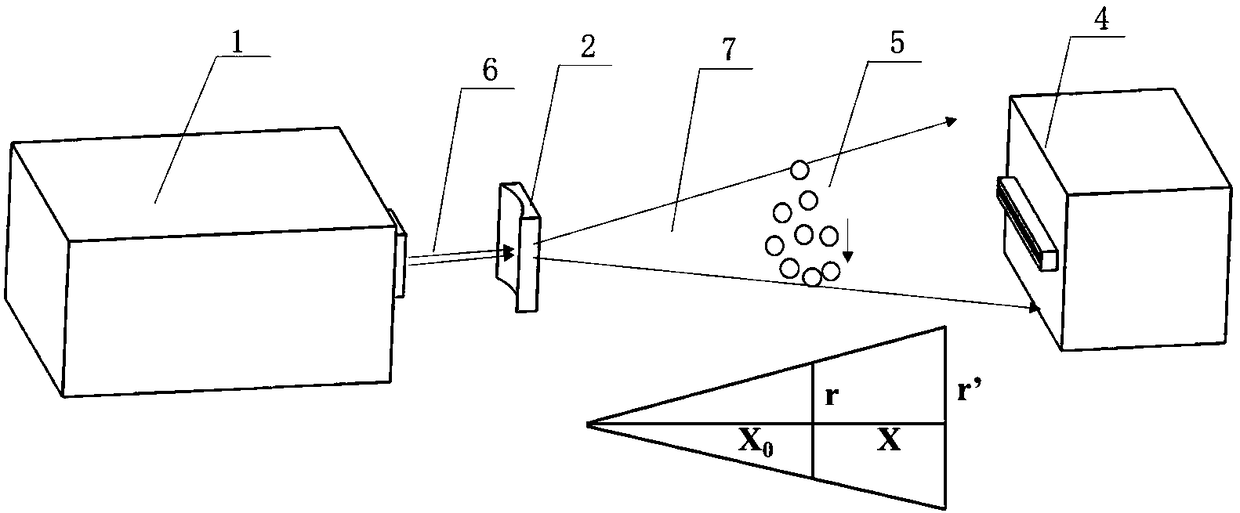

[0065] Such as figure 2 In the holographic real-time measuring device shown, the laser light source 1, the plano-concave cylindrical lens A2, and the line array camera 4 are arranged on the same axis according to the sequence, which is a coaxial holographic form.

[0066] The method for measuring the particle size using the holographic real-time measuring device of this embodiment is as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com