Calibration device and method for orthogonality and gain consistency of three-axis magnetic sensor

A sensor and three-axis magnetic technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of poor calibration accuracy, low efficiency, and complicated debugging process, and achieve the effect of improving calibration work efficiency and calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

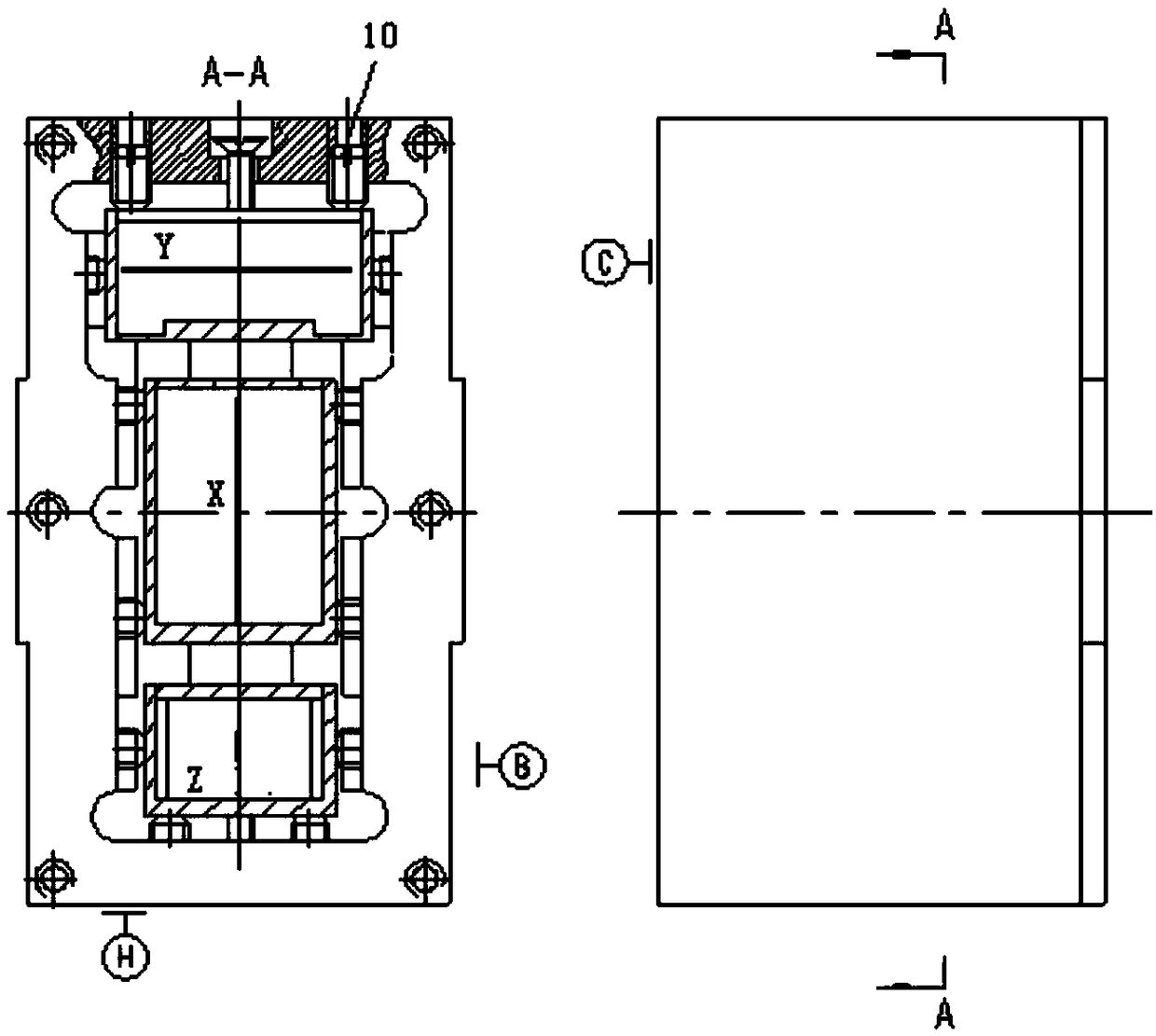

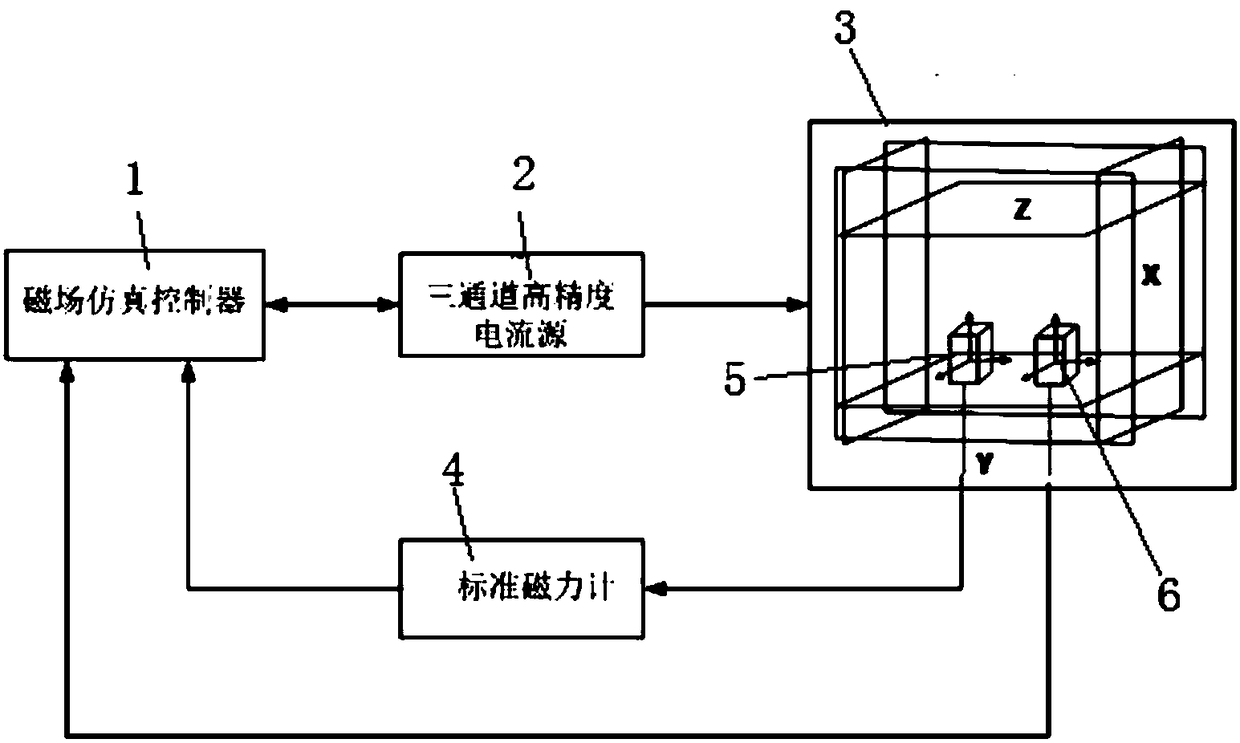

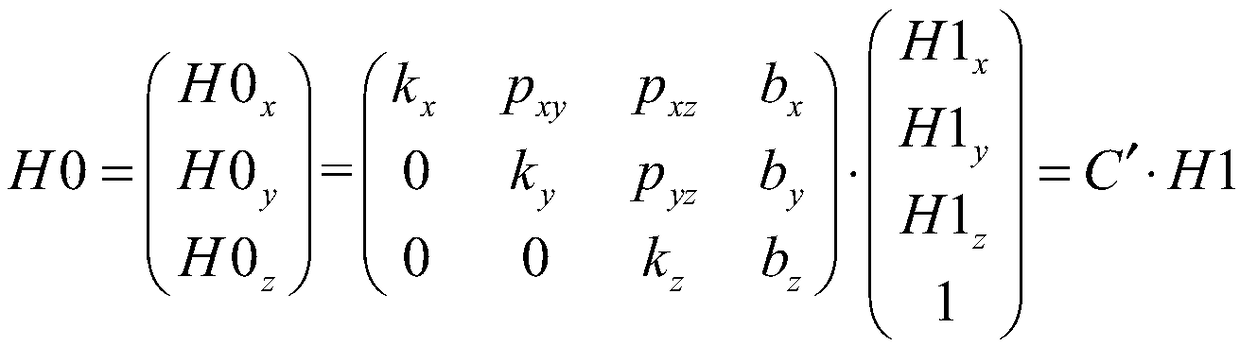

[0021] Such as figure 2 As shown, a set of calibration device for orthogonality and gain consistency of three-axis magnetic sensors used in this calibration method is mainly composed of four parts: a set of magnetic field simulation controller 1, magnetic field simulation control and calculation software loaded In the magnetic field simulation controller 1; a set of three-channel high-precision current source 2; a set of three-dimensional coils 3; a set of high-precision standard magnetometer 4, the high-precision standard magnetometer 4 is a standard magnetometer with qualified measurement. The three-dimensional coil 3 is composed of three sets of mutually orthogonal coils in the X direction, the Y direction and the Z direction. The standard magnetic sensor 5 and the three-axis magnetic sensor 6 to be calibrated (one or more) are fixed in the homogene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com