A machining error analysis method based on installation error extraction and correction

A technology of installation error and analysis method, applied in measurement devices, instruments, geometric CAD and other directions, can solve the problems of not reflecting the worm machining error, installation and alignment is cumbersome, etc. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

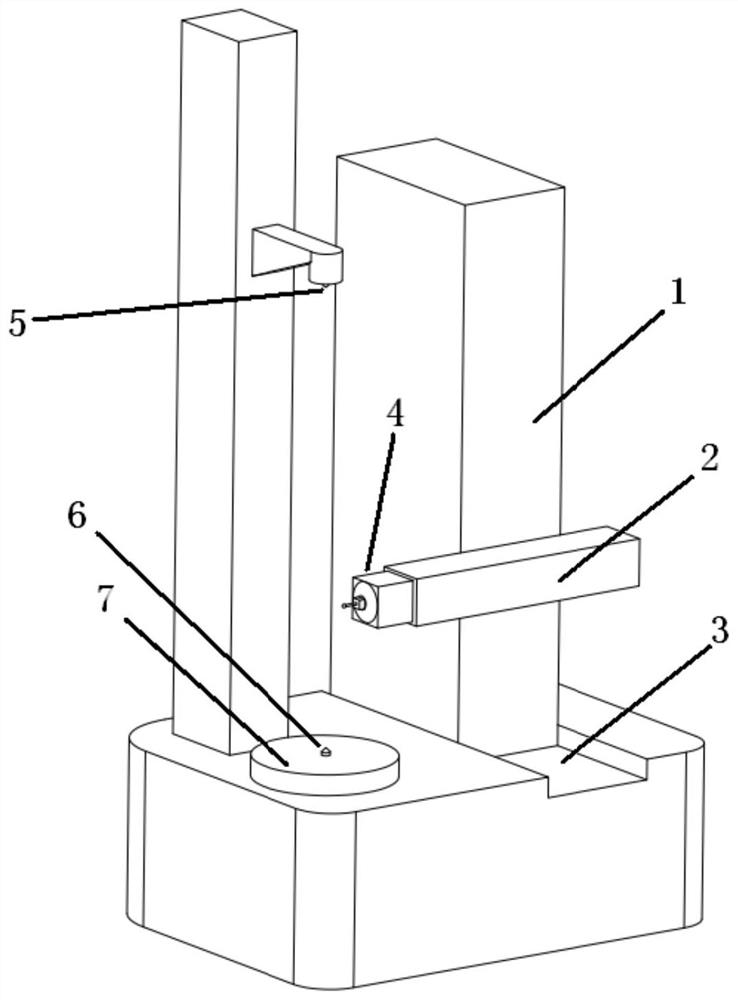

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

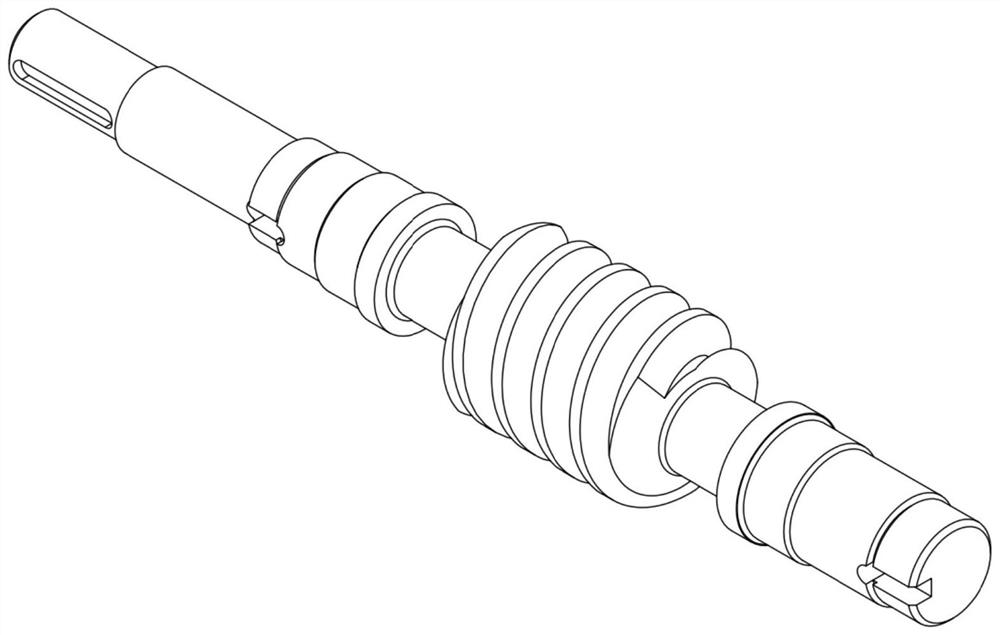

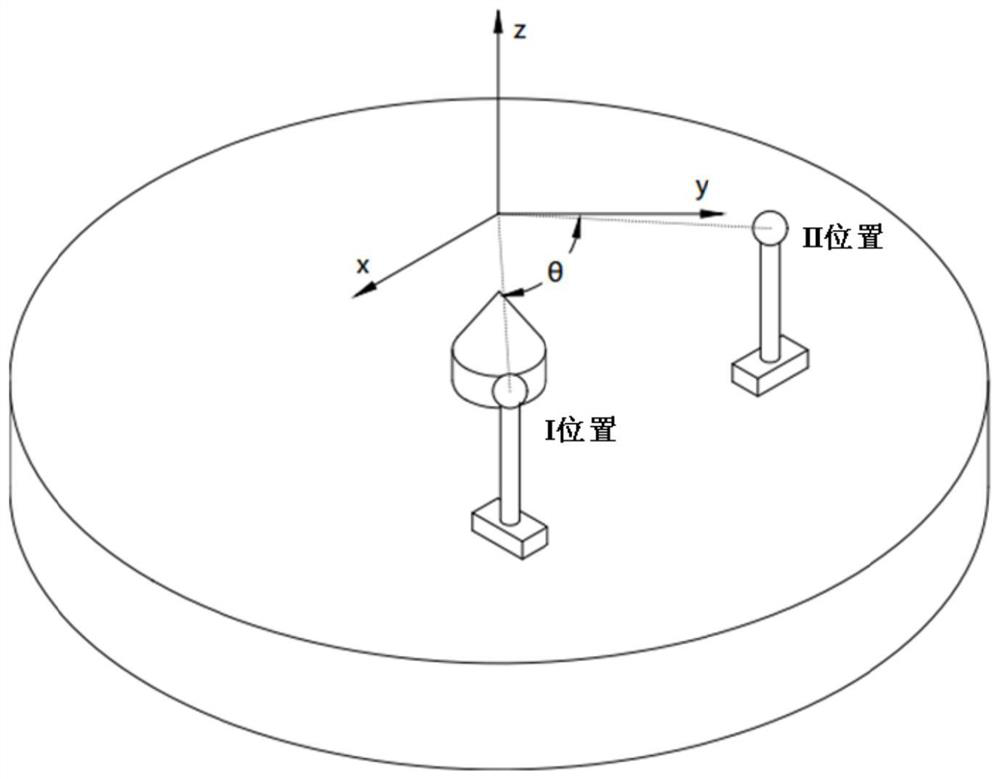

[0027] For the worm without upper and lower tops and the machining error measurement that has a large deviation between the axis of the worm and the axis of rotation of the measuring platform after the top is clamped, if the installation error is not corrected, and the measurement results are used as the basis for judging whether the worm is qualified, Since the installation error is not eliminated, the measurement result of the qualified worm will be poor, and it will be misjudged as a waste product. The above problems also exist in the analysis of machining errors of other workpieces similar to worms (such as rotary workpieces). For this reason, the present invention firstly proposes a worm screw eccentricity and tilt installation error extraction and correction method based on a four-axis measurement center, including the following steps, see Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com