A method of cutting pvc board based on mark point positioning function

A PVC board and point positioning technology, applied in the direction of instruments, image feedback, manufacturing tools, etc., can solve the problems of low efficiency, large error, and long time consumption, and achieve the effects of strong robustness, small loss of precision, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The invention will be described in detail below with reference to the accompanying drawings.

[0057]ReferFigure 1 ~ 6A method of cutting a PVC board based on a MARK point positioning function, including the following steps:

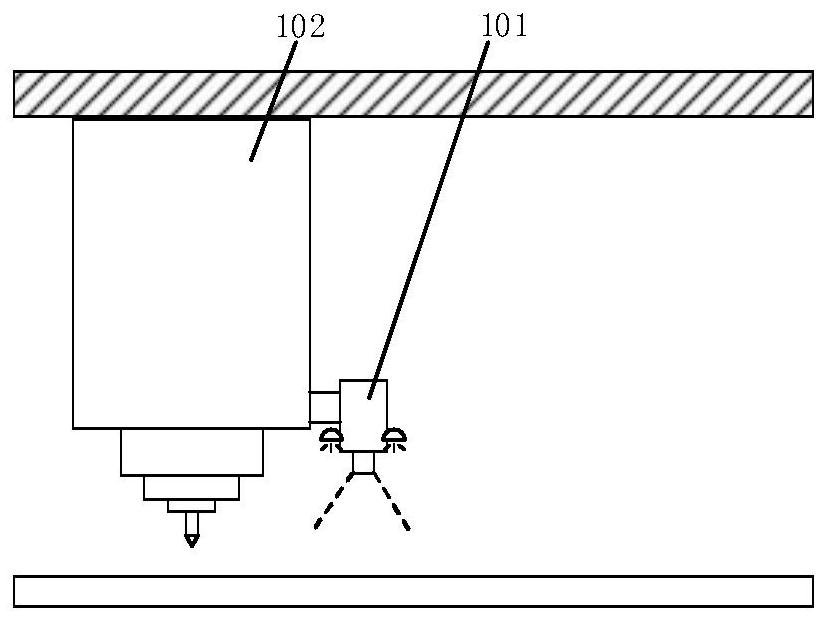

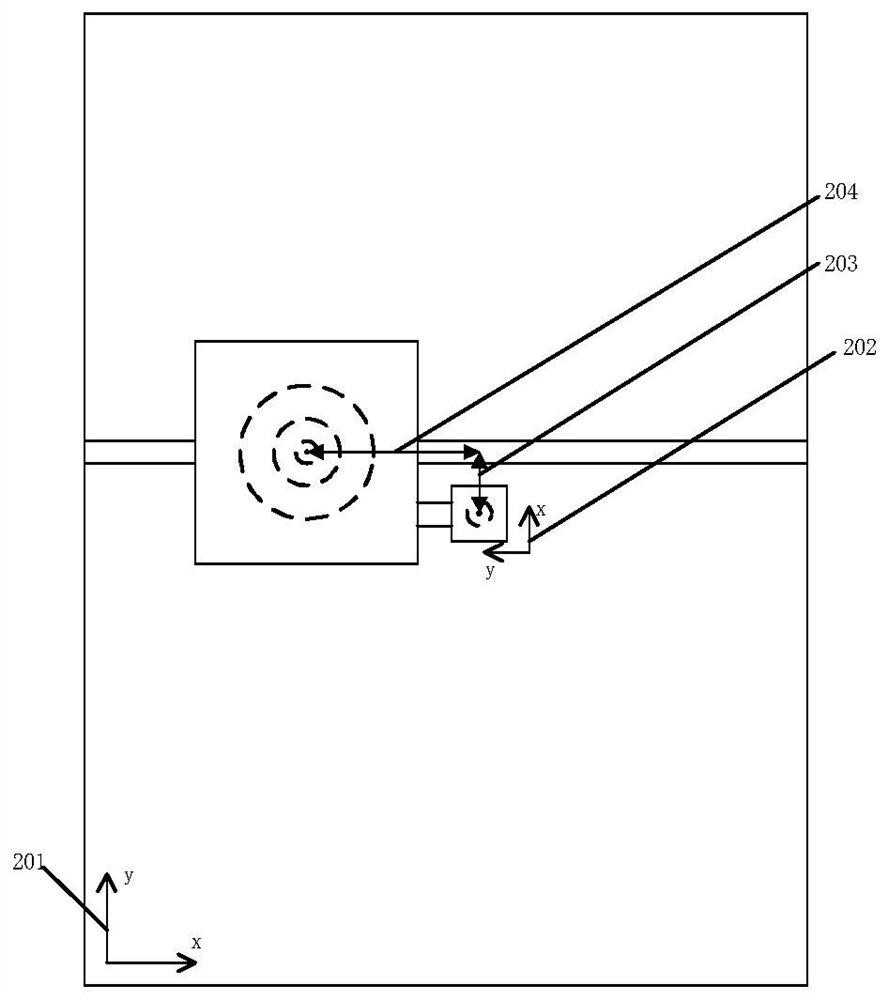

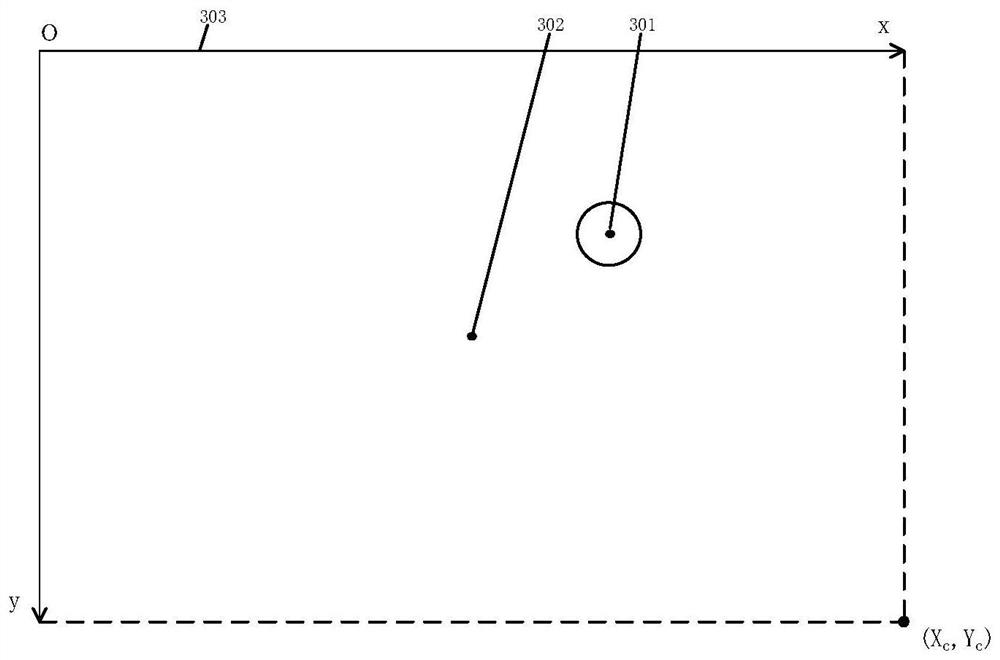

[0058]1) First, iffigure 1 The industrial camera is displayed to the position near the spindle of the engraving and milling machine, such asfigure 2 The function of the camera and the spindle is shown by the camera bias to the camera and the main shaft relative offset XsSums. Proportion of coordinates and actual working coordinate systems in known cutting files1: 1. Calculate the transition ratio in the camera coordinate system and the cutting file program by the current height camera MARK point imaging.2: 1, such asimage 3 The maximum range of the camera coordinate system is (xcYc).

[0059]2) Second, the engraving and milling machine is based on the cutting program file to find the strategy of Mark points, such asFigure 4 Indicated.

[0060]3) According to step 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com