Hanger of container reach stacker

A technology of reach stackers and containers, which is applied in the field of spreaders, can solve the problems of accidental falling off of containers and inconvenient rapid grabbing of containers, and achieve the effects of improving the efficiency of grabbing containers, preventing accidental falling off, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

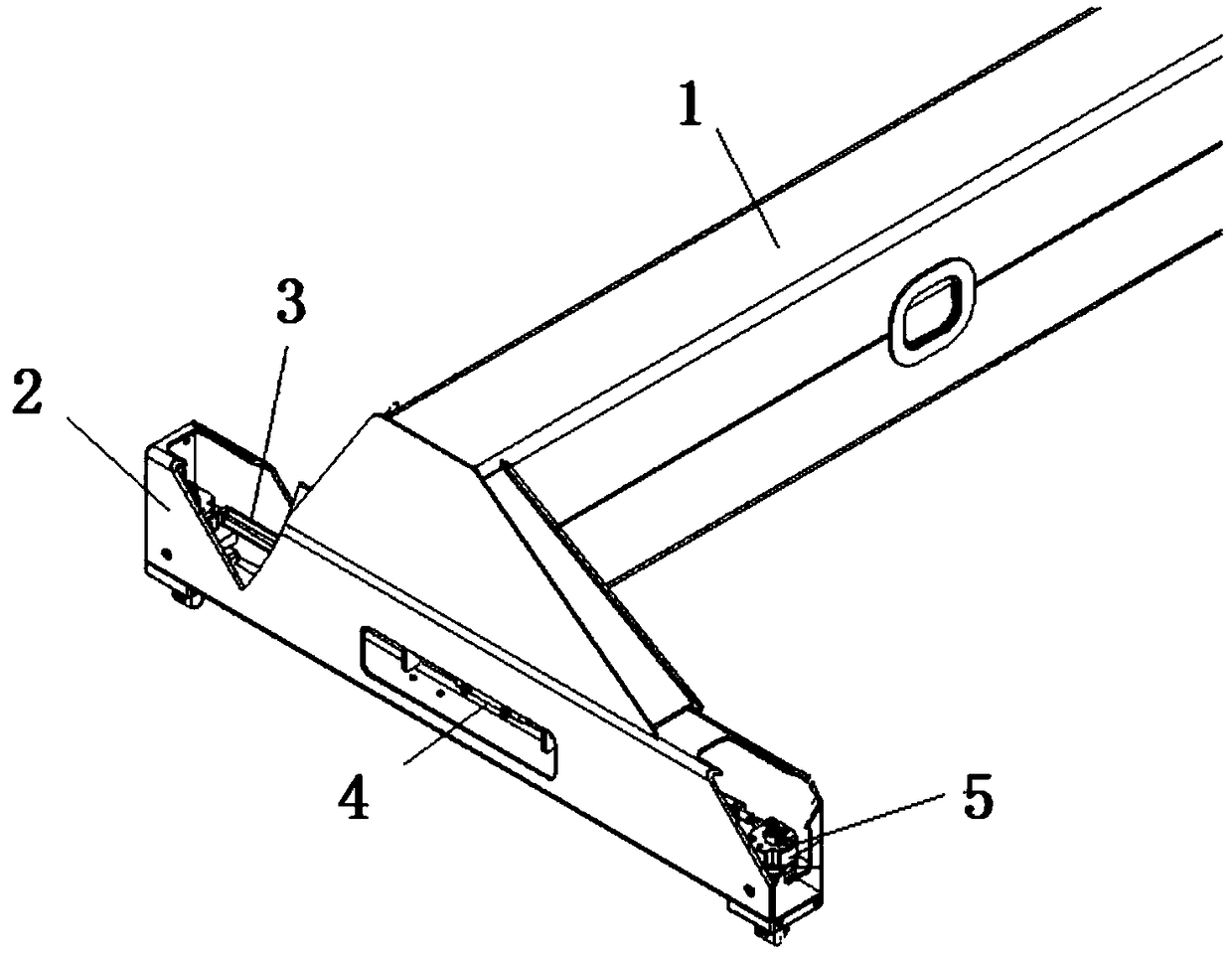

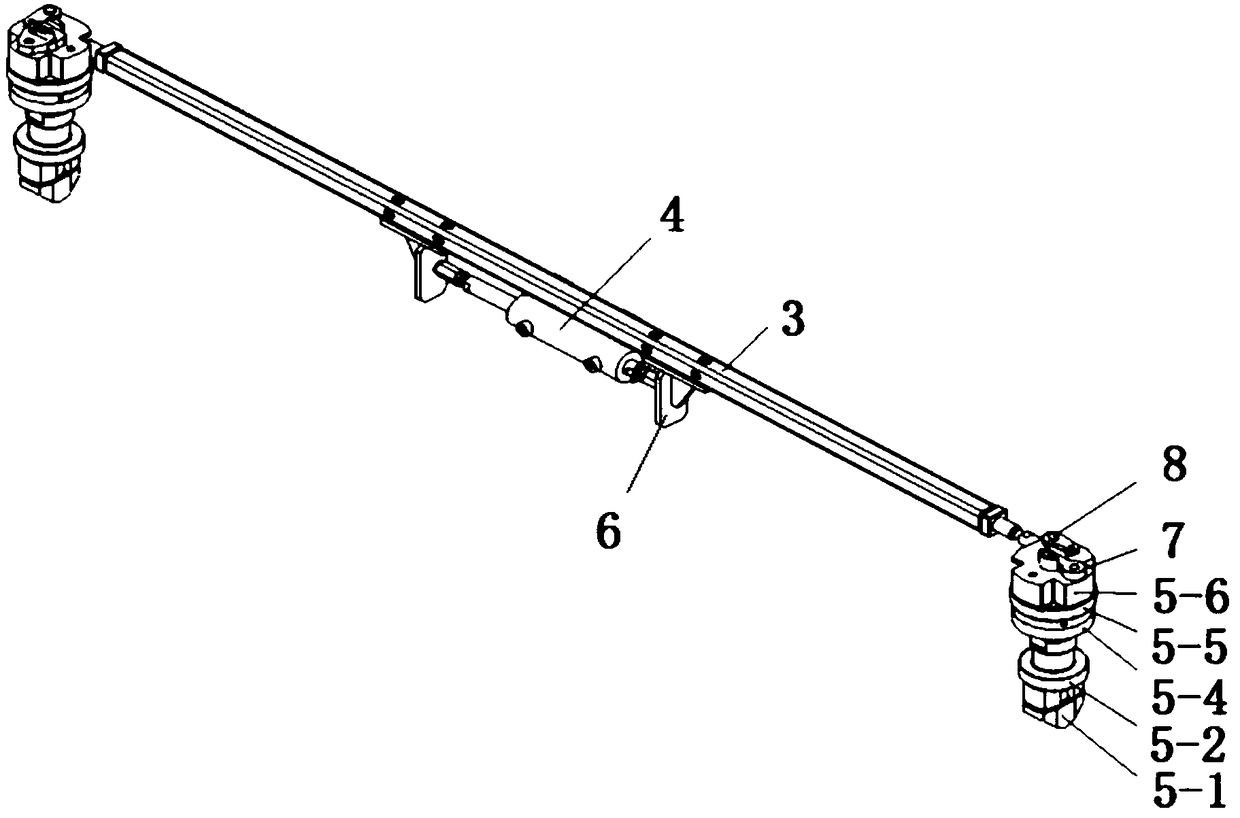

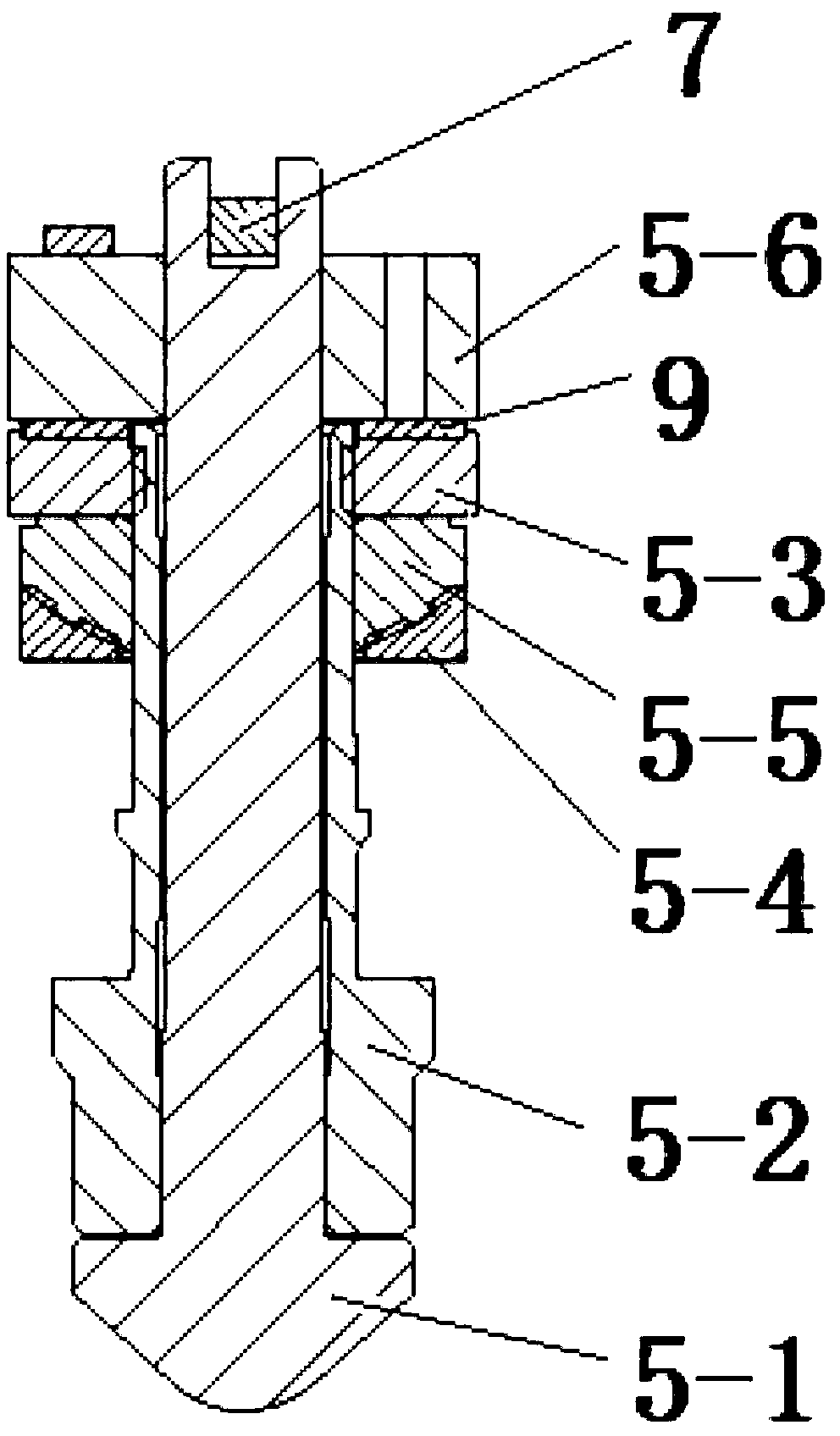

[0023] Embodiment 1: The present invention provides a technical solution: a container front loader spreader, comprising a connecting frame 2 connected to the two ends of the fixed arm 1 (such as figure 1 as shown, figure 1 Only part of the schematic diagram is drawn), the connecting frame 2 is horizontally provided with a connecting rod 3 and a bidirectional driving device 4, the bidirectional driving device 4 is fixedly connected to the connecting frame 2, and the connecting rod 3 is driven by the bidirectional driving device 4 to move along its axial direction; It should be noted that the two-way driving device 4 is a double-rod hydraulic cylinder or a double-rod cylinder, and the connecting rod 3 is fixedly connected with two baffles 6, and the two piston ends of the two-way driving device 4 are located between the two baffles 6, Two piston ends of preferred two-way driving device 4 are in contact with the side wall of baffle plate 4, thereby drive connecting rod 3 to drive...

Embodiment 2

[0027] Embodiment 2: In Embodiment 1, "a spreader 5 is hinged at one end of the connecting rod 3" is changed to "a spreader 5 is hinged at both ends of the connecting rod 3", and the rest is the same as that of Embodiment 1.

[0028] Working principle: when the spreader 5 is in use, the two-way driving device 4 pushes the connecting rod 3 to make a linear motion, and the connecting rod 3 pushes the two locking plates 5-6 to rotate through the pin shaft 8, and the locking plate 5-6 drives the lock head 5-1 to synchronize Rotate to 90°, after the lock head 5-1 rotates 90°, the elliptical step surface cannot be pulled out from the container waist hole, and the lock head 5-1 can hook the container waist hole to complete the container lifting and transportation. When the two lock heads 5-1 are inserted into the waist-shaped hole of the container, the stability when the lock head 5-1 is hooked up with the container is increased; The rod 3 drives the lock plate 5-6 and the lock head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com