Main structure and system of L-shaped organic solid waste carbon gasifier

A technology of organic solid waste and main structure, applied in the direction of incinerator, combustion type, steam generation method using heat carrier, etc., to achieve the effect of no need for desulfurization and denitrification, harmonious and unified environment, and reduction of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

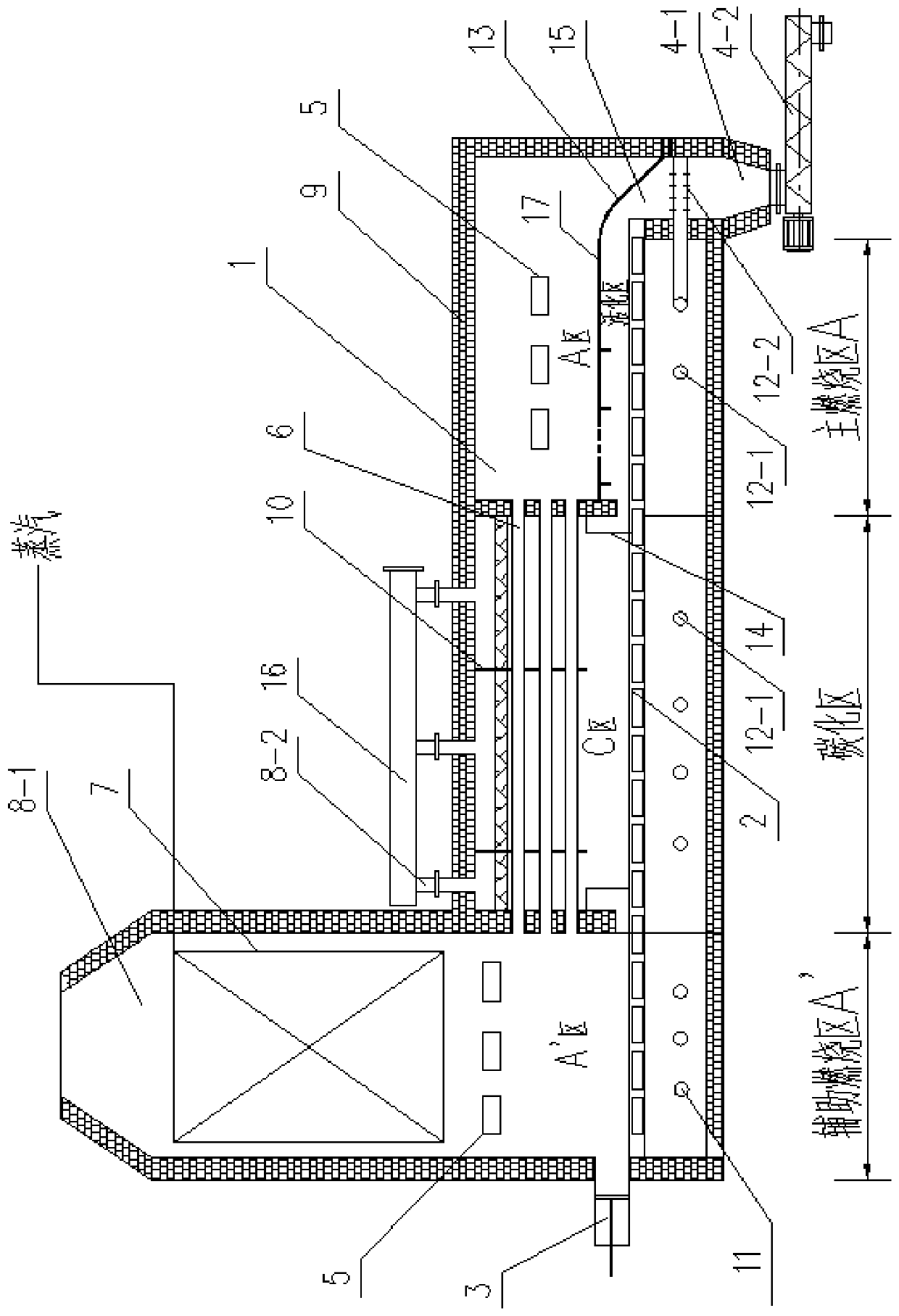

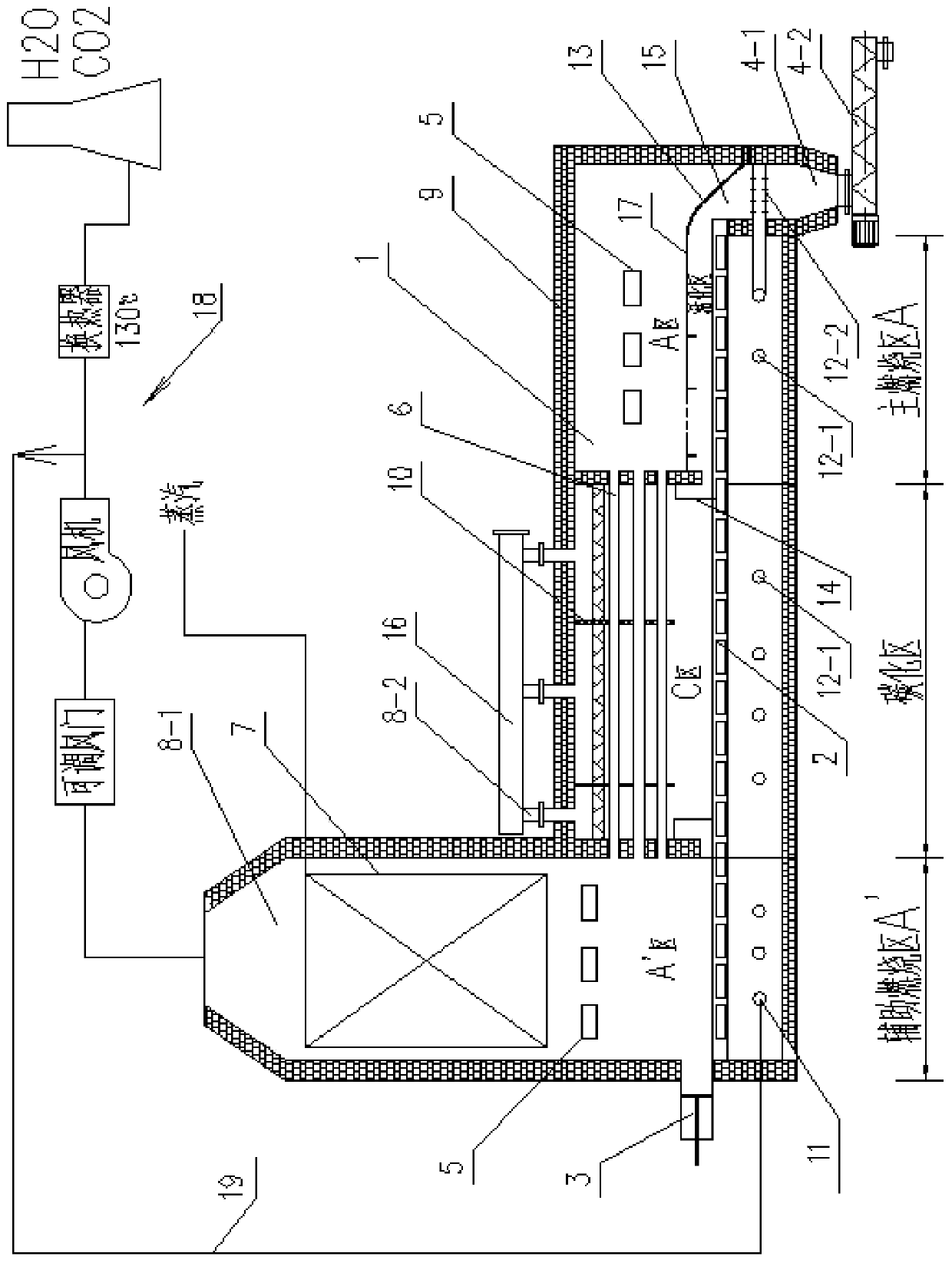

[0043] Such as figure 1 Shown is an embodiment of the main structure of an L-shaped organic solid waste charcoal gasifier. According to the implementation of this example, the main structure of the charcoal gasifier is mainly divided into three areas, which are composed of auxiliary combustion chamber A ', built-in radiant heating tube carbonization chamber C and main combustion chamber A, these three areas are arranged in sequence from the feeding side to the discharging side of the carbonization furnace.

[0044] Above-mentioned each district is divided by heat-resistant furnace wall 9, thereby makes the furnace gas of each district in the furnace not communicate with each other between carbonization chamber C and main combustion chamber A, auxiliary combustion chamber A'. 10 partitions are arranged in the carbonization chamber C to form segmental output of pyrolysis gas. Several direct heating burners 5 are installed in the auxiliary combustion chamber A', and a feeding an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com