A treatment method for steel rolling oily sludge

A treatment method, oil sludge technology, applied in sludge treatment, water/sludge/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of high iron content, long treatment process, high energy consumption, etc., and reach the total iron content High efficiency, low operating cost, and low processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

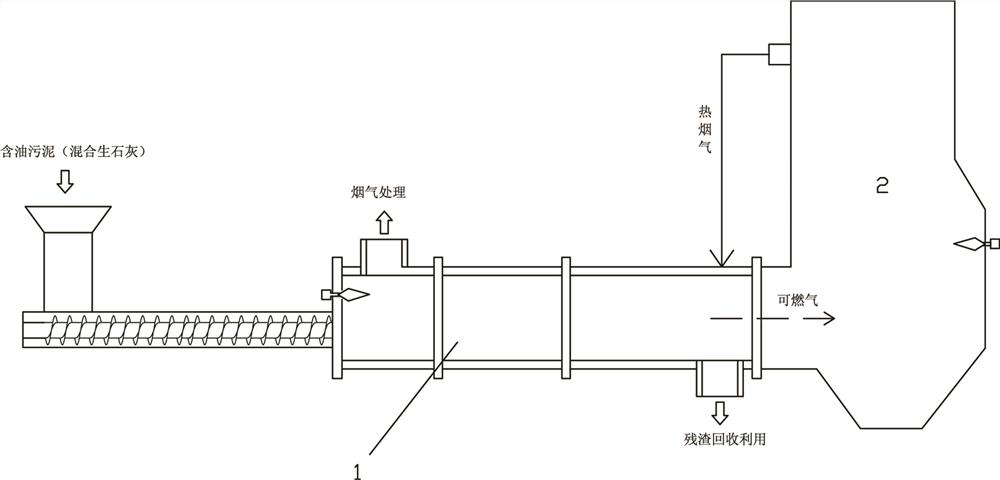

Embodiment 1

[0038] 1. The oily sludge produced by hot-rolling circulating water treatment has an oil content of 7.4%, a water content of 18.1%, and a total iron content of 48.5% (dry basis). 200 meshes of 5% quicklime powder are added to it, and after mixing, it is fed to the sludge by a screw. The feeder is sent into the kiln head of the rotary kiln reactor, and the process parameters in the rotary kiln reactor are controlled as follows: temperature 400°C, air excess coefficient 0.5, reaction time 20min; the average concentration of CO in the discharged combustible gas is 2500ppm, and the The combustible gas is ignited, and the hot flue gas with a temperature of 580°C is returned to the outer jacket of the rotary kiln reactor as an external heat source, and the flue gas after heat exchange is discharged after subsequent treatment; the rotary kiln tail is deoiled The final residue has a total iron content of 60.4%, a CaO content of 10.4%, a total carbon content of 2.4%, an oil content and ...

Embodiment 2

[0040] The oily sludge produced by the treatment of a thick plate circulating water has an oil content of 4.5%, a water content of 15.1%, and a total iron content of 51.6 (dry basis). 200 meshes of 3.5% quicklime are added to it, mixed and passed through a screw feeder Send it into the kiln head of the rotary kiln reactor, and control the process parameters in the rotary kiln reactor as follows: temperature 360°C, air excess coefficient 0.4, reaction time 15min; the average concentration of CO in the discharged combustible gas is 1358ppm, which can be The gas is ignited, and the hot flue gas with a temperature of 520 ° C is returned to the outer jacket of the rotary kiln reactor as an external heat source. The flue gas after heat exchange enters the subsequent treatment and is discharged; The total iron content of the residue is 60.6%, the CaO content is 8.4%, the total carbon content is 2.1%, the oil content and water content are zero, and it is back-sintered for production an...

Embodiment 3

[0042] The oily sludge produced by the first rolling circulating water treatment has an oil content of 9.9%, a water content of 22%, and a total iron content of 47.6% (dry basis). 7.5% quicklime is added to it, and after mixing, it is sent to the sludge by a screw feeder. into the kiln head of the rotary kiln reactor, and the process parameters in the rotary kiln reactor are controlled as follows: temperature 450°C, air excess coefficient 0.7, reaction time 25min; the average concentration of CO in the discharged combustible gas is 2710ppm, and the combustible gas Ignite, return the hot flue gas with a temperature of 700°C to the outer jacket of the rotary kiln reactor as an external heat source, and the flue gas after heat exchange will be discharged after subsequent treatment; the residue after deoiling at the rotary kiln tail The total iron content is 59.8%, the CaO content is 11.6%, the total carbon content is 2.3%, the oil content is less than 0.1%, and the moisture conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com