Low-floor bogie driving unit and low-floor bogie

A drive unit and bogie technology, which is applied to the transmission device driven by the motor, etc., can solve the problem of reducing the lateral space of the motor, and achieve the effect of reducing the height, lowering the maintenance cost, and improving the curve passing ability of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below with reference to specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0030] For the convenience of description, the relative positional relationship of each component, such as: upper, lower, left, right, etc., are described according to the layout direction of the drawings in the specification, and do not limit the structure of this patent.

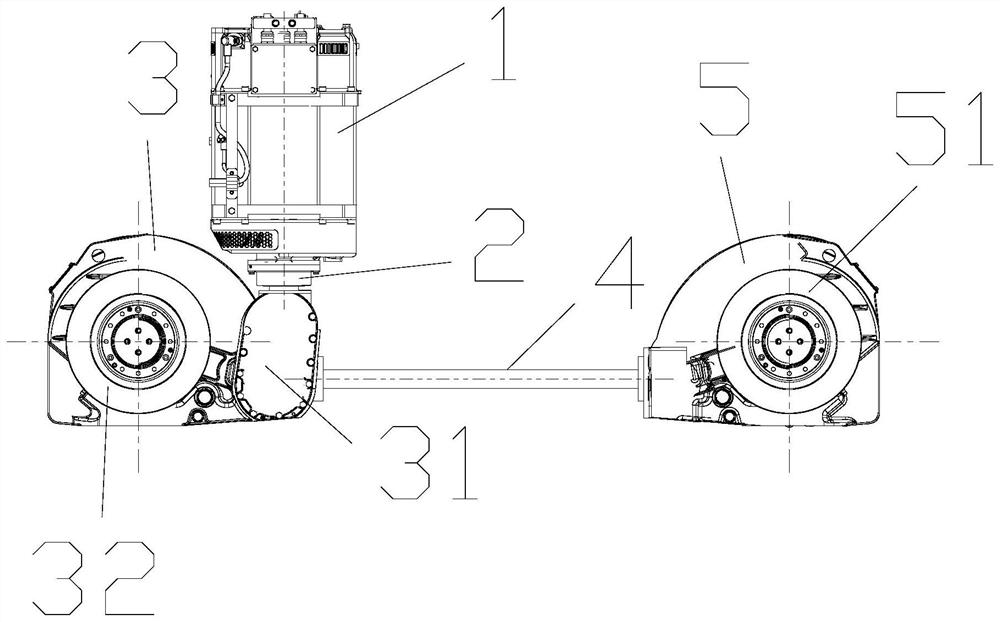

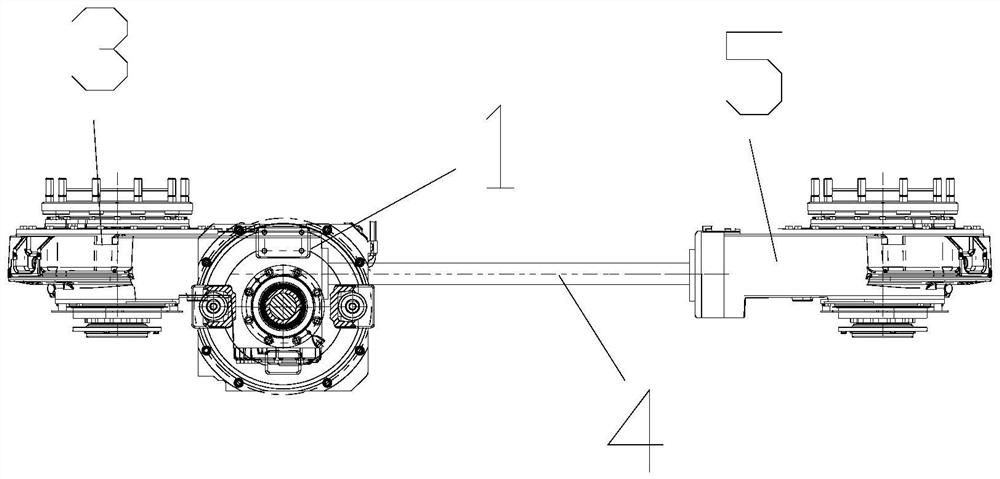

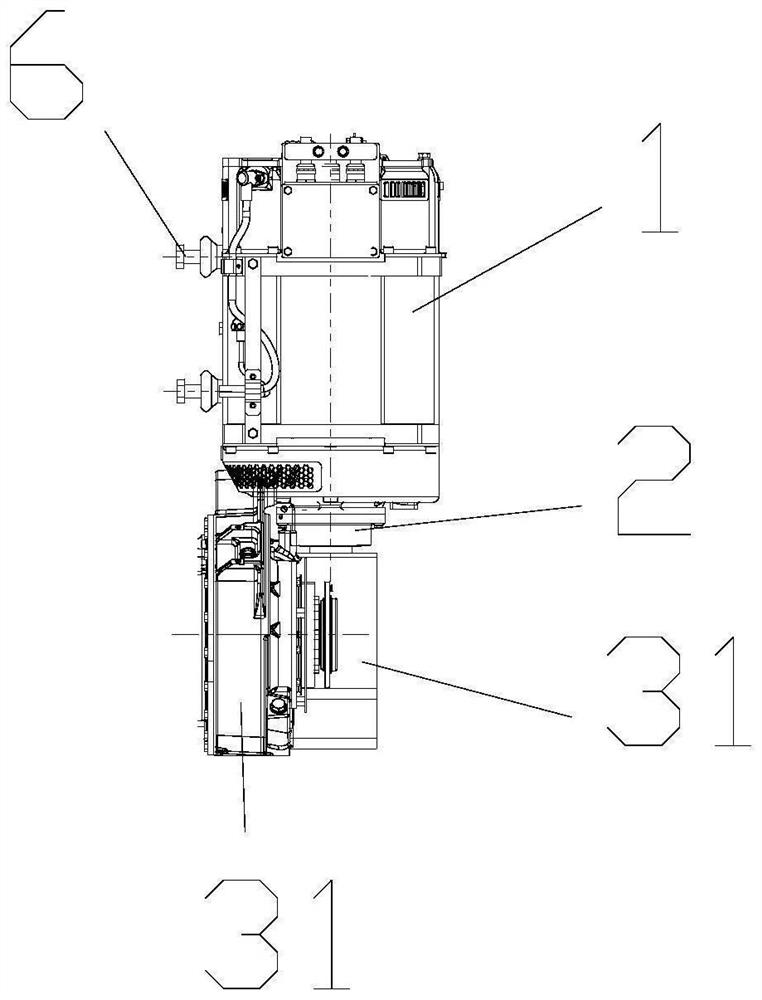

[0031] like figure 1 - Image 6 As shown, an embodiment of the low-floor bogie drive unit and the low-floor bogie of the present invention mainly includes a drive motor 1, a set of couplings 2, a first gear box 3, a link device 4, 1 second gear box 5 is composed.

[0032] The drive motor 1 , the first gear box 3 and the second gear box 5 are respectively mounted on the outside of the bogie frame 7 . A motor mounting seat 8 is vertically arranged on the outer side of the bogie frame 7 , and the driving motor 1 is vertically m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com