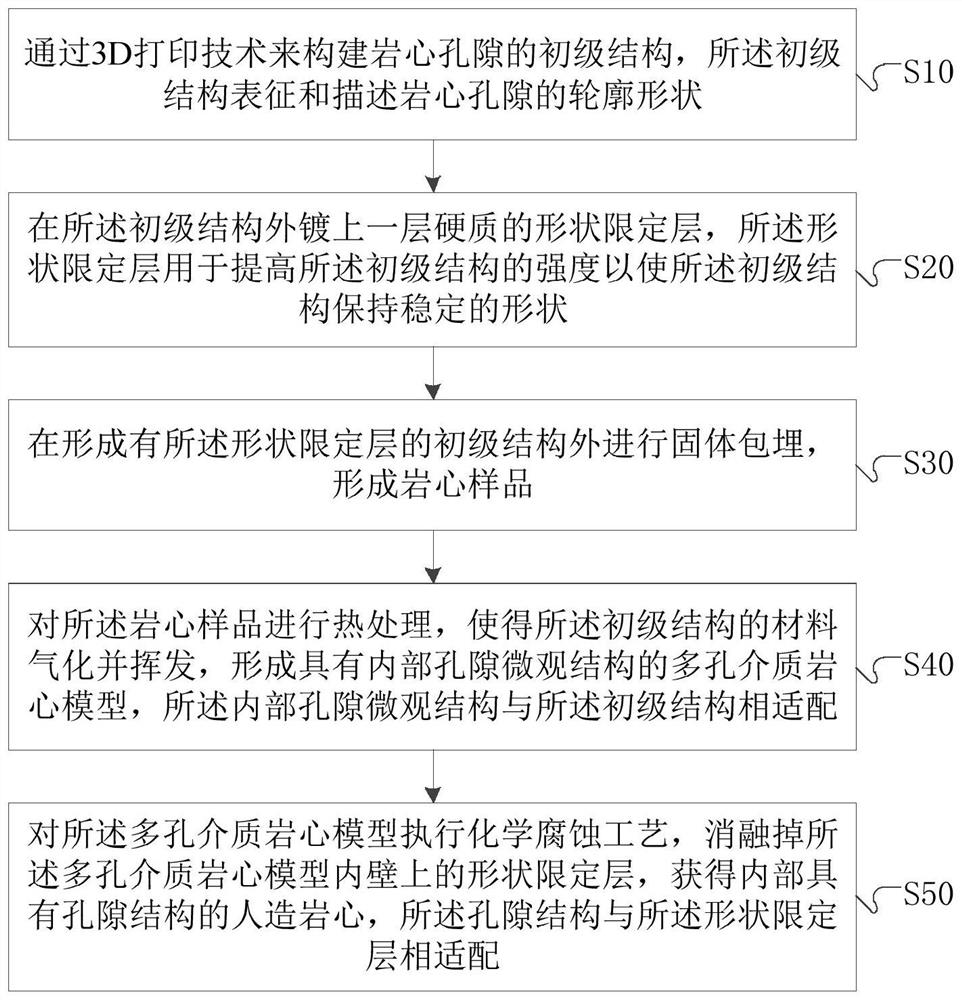

A method and device for preparing an artificial core

An artificial core and core technology, which is applied in the field of artificial core preparation, can solve the problems of limited application range of artificial core, poor temperature and pressure resistance, and inability to simulate the environment by physical simulation, and achieve low requirements, smooth and accurate inner wall surface, and easy The effect obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

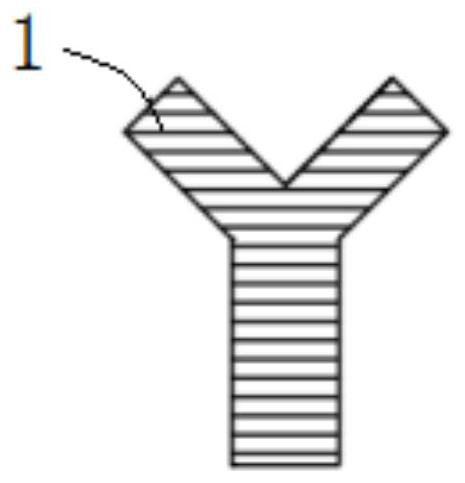

[0071] However, in the method for preparing the artificial core provided by the embodiment of the present invention, firstly, the primary structure 1 used to characterize and describe the shape of the pore contour is printed out with printing consumables through 3D printing technology, instead of printing out the three-dimensional shape of the pore as in the above-mentioned known embodiment. Print mineral grain or mineral powder slurry like that, form pores in mineral grain or mineral powder slurry.

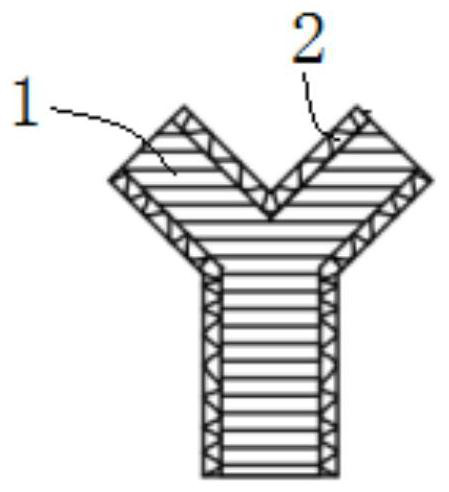

[0072]Subsequently, a hard shape-defining layer 2 is plated on the outer wall of the printed three-dimensional primary structure 1 for characterizing and describing the shape of the pore outline, so as to stabilize the shape of the primary structure 1 . Then, solid embedding filling is performed outside the primary structure 1 formed with the shape-defining layer 2 , and the solid embedding filling forms the filling matrix 3 as the skeleton of the final artificial core 8 , thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com