Motor controller

A motor controller and controller technology, which is applied to electrical components, circuit thermal devices, printed circuit components, etc., can solve the problems of affecting heat dissipation, sensitive thermal performance of Jingyuan, and slow thermal response of circuit substrates. The effect of enhancing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The concrete implementation method of the present invention is as follows:

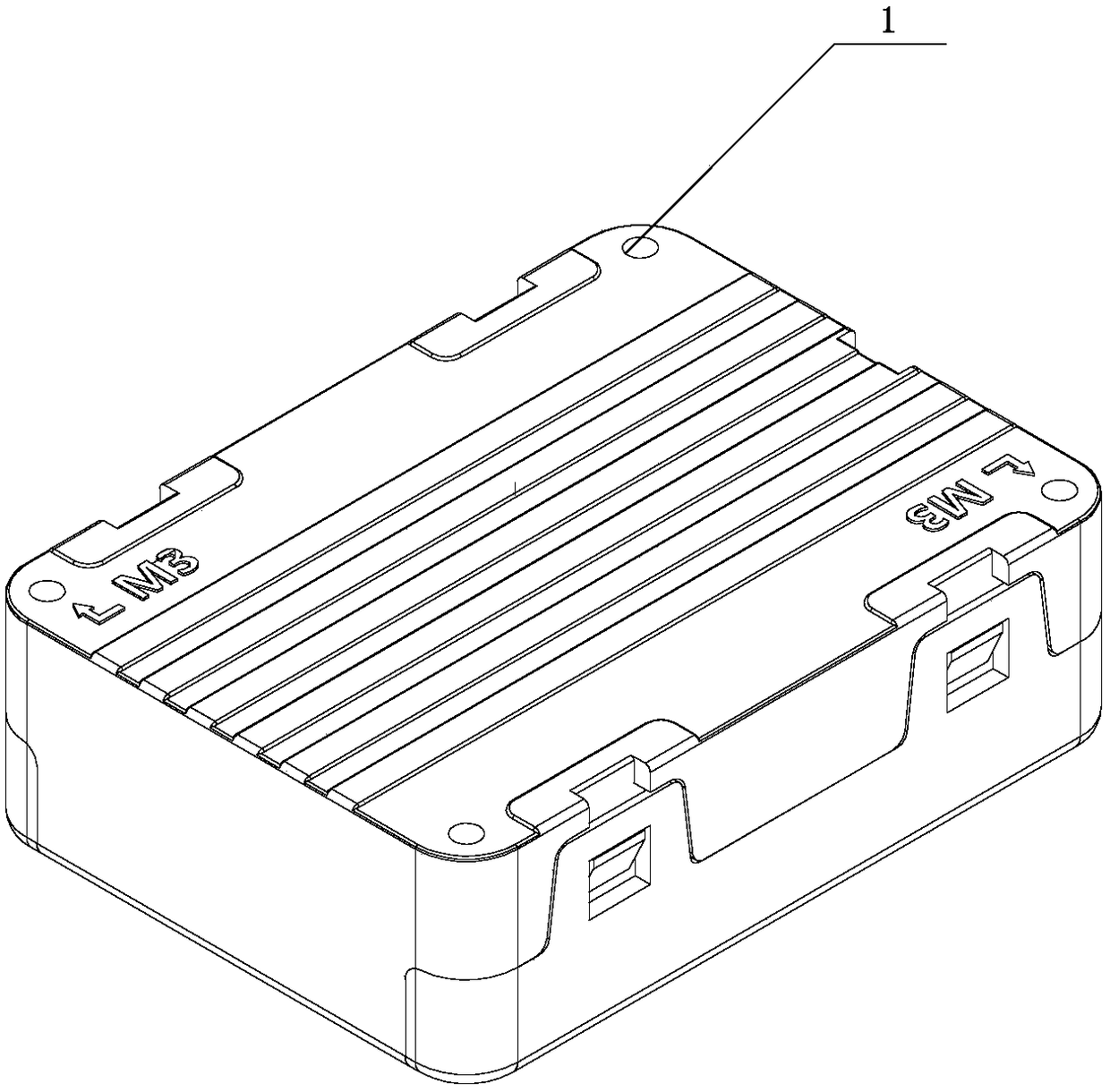

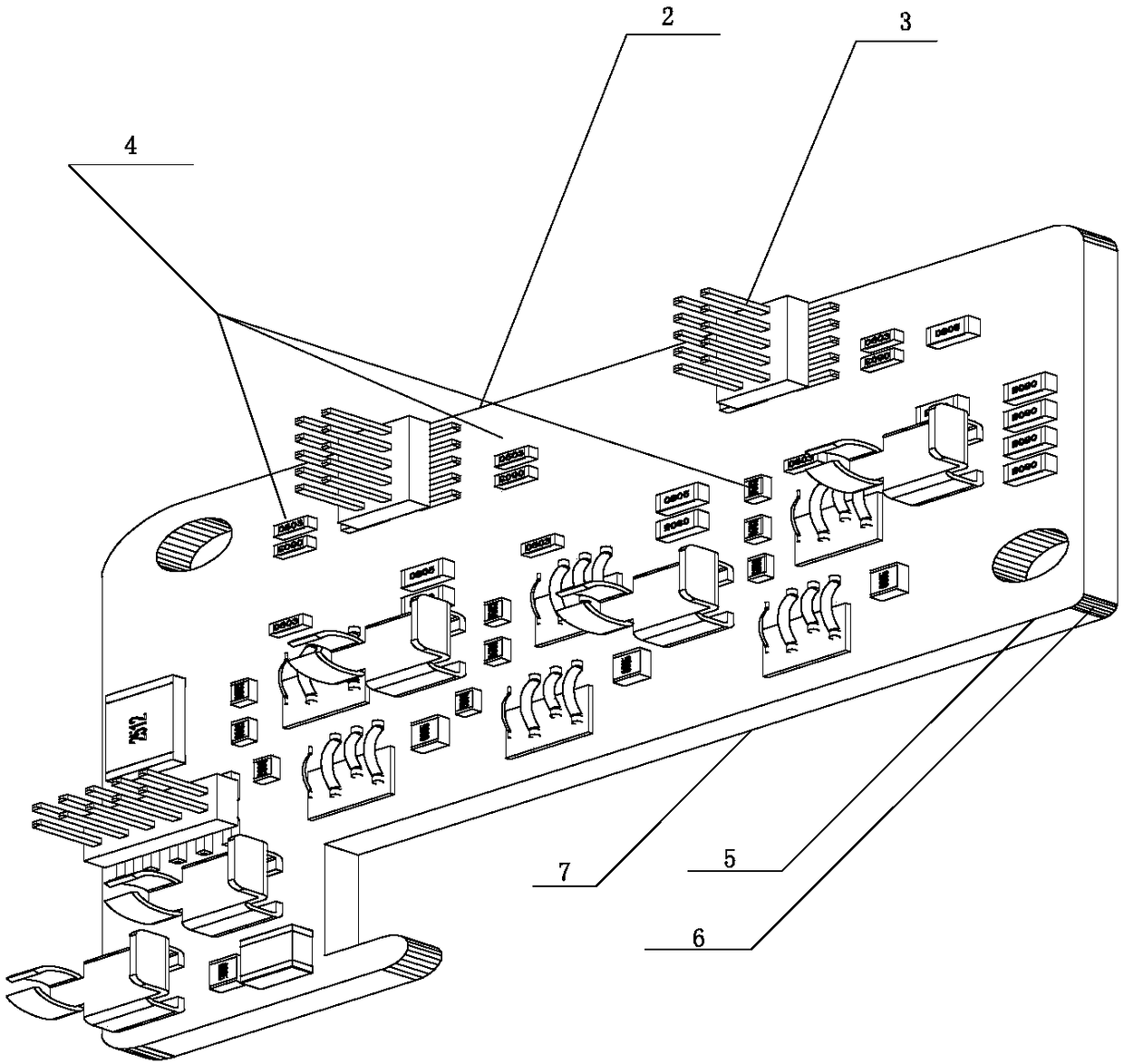

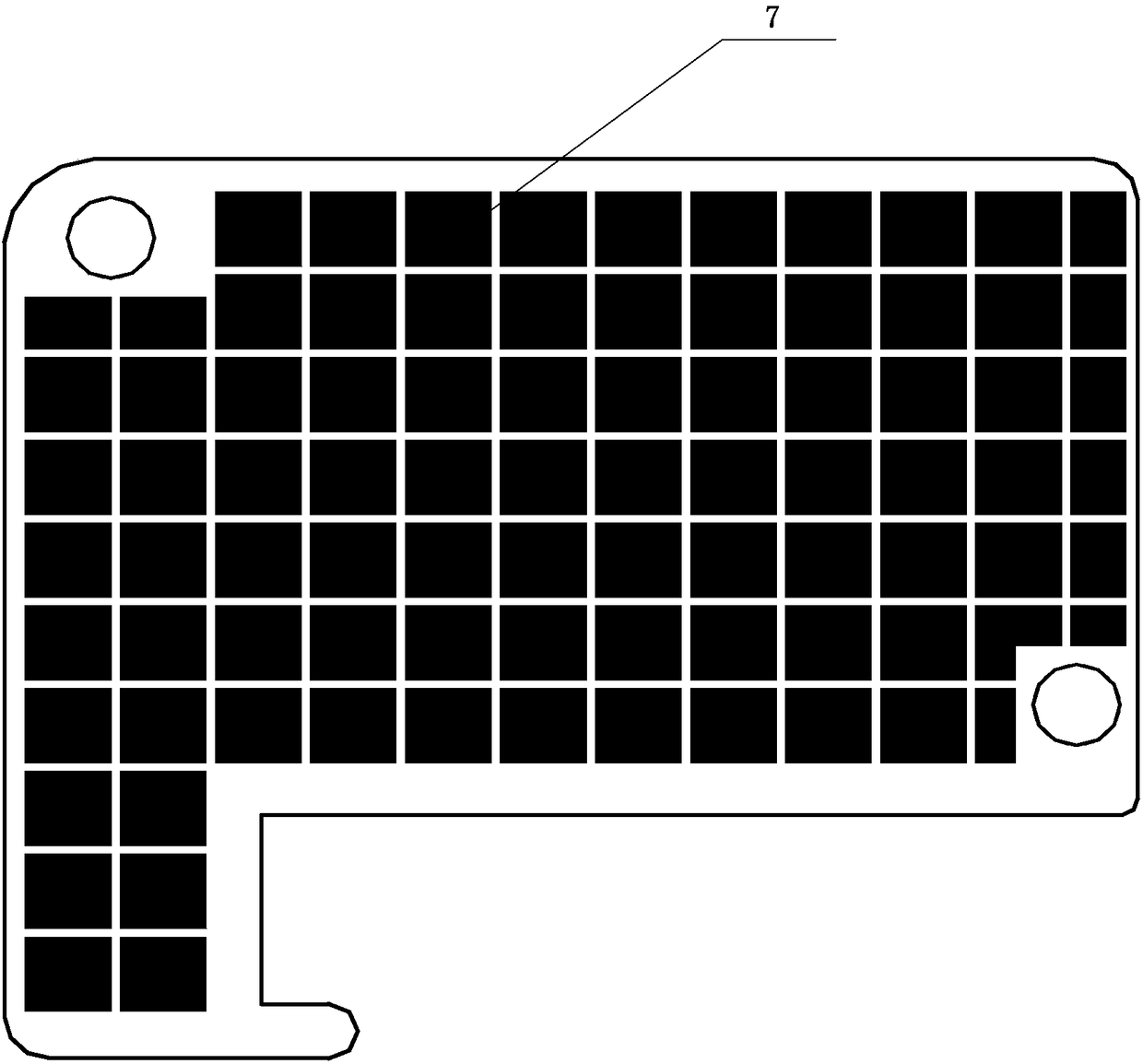

[0016] according to Figure 1-3 As shown, 1 is the controller housing, 2 is the circuit substrate, 3 is the plug terminal, 4 is the electronic component, 5 is the electronic component layer, 6 is the ceramic substrate layer, and 7 is the thin metal layer.

[0017] The electronic components 4 and the socket terminals 3 are mounted on the circuit substrate 2, and the circuit substrate 2 is located in the controller casing 1, and the controller casing 1 meets the IP55 waterproof requirement. The controller casing 1 embeds a circuit substrate 2 and electronic components 4 into the casing. The circuit substrate 2 is divided into an electronic component patch layer 5 and a ceramic substrate layer 6 .

[0018] A thin metal layer 7 is printed under the ceramic substrate layer 6 . The thin metal layer can be a copper clad layer, or other thin metal layers with good ductility. The thin metal layer can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com