Optical fiber cable

A technology of optical fiber cables and optical fibers, applied in the field of optical fiber cables, to achieve the effects of reducing the number of uses, easy removal operations, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

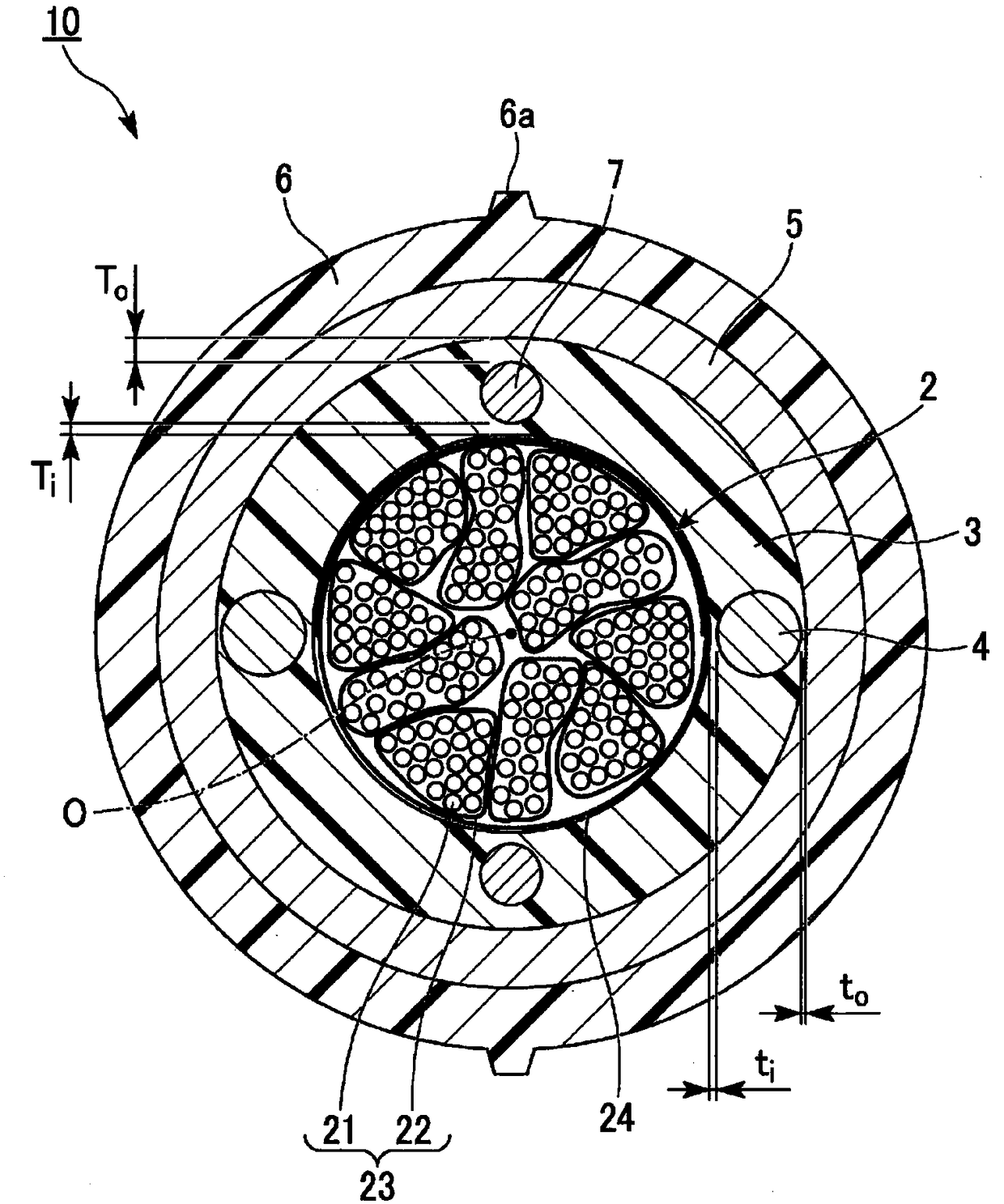

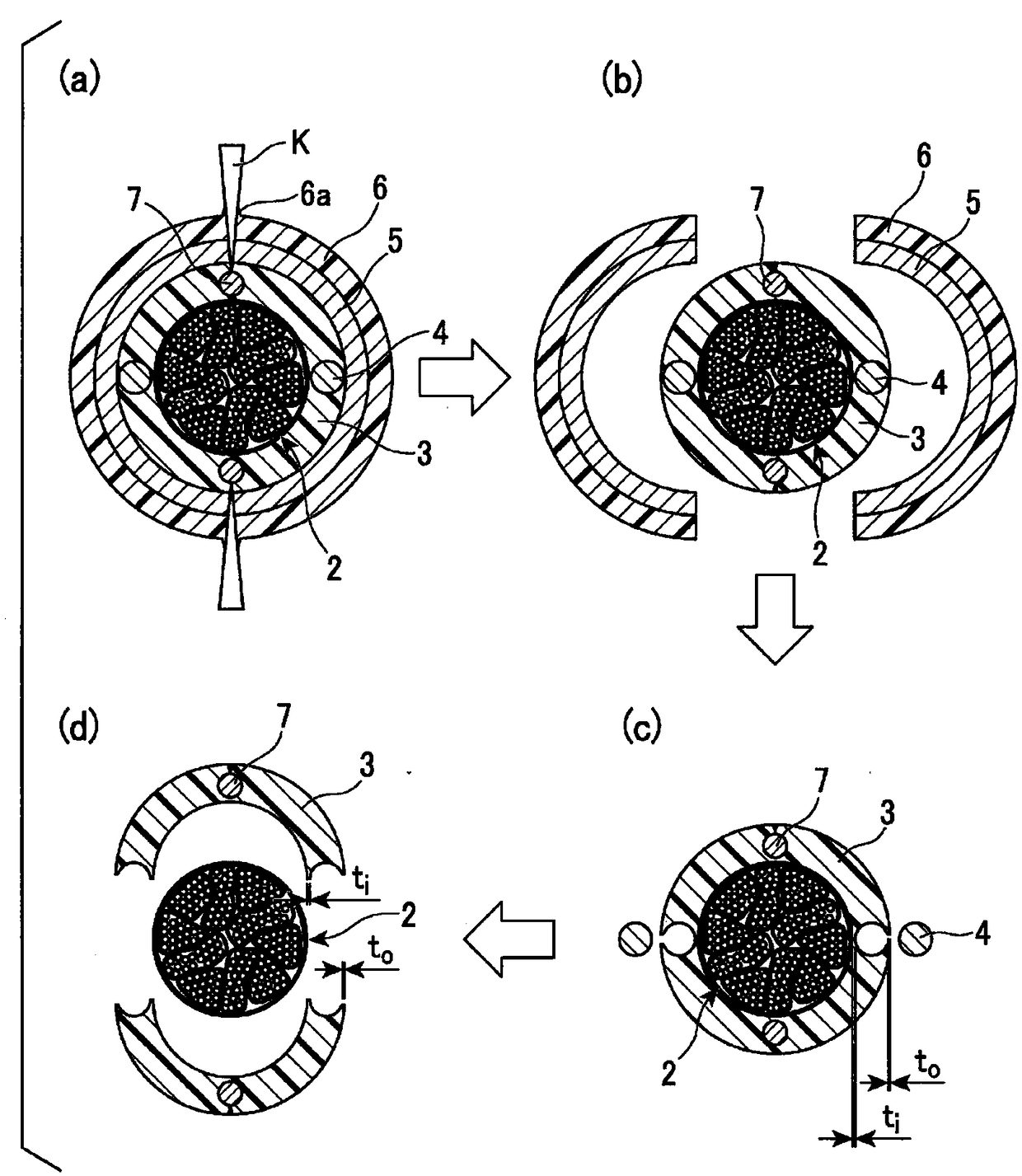

[0055] Below, refer to figure 1 , figure 2 , the structure of the optical fiber cable 10 of the first embodiment will be described. In addition, the scales of the drawings used in the following description are appropriately changed so that the shape of each component can be recognized.

[0056] like figure 1 As shown, the optical fiber cable 10 includes a core 2 , an inner sheath 3 , a pair of linear bodies 4 , a pair of tensile members 7 (tension members), a reinforcing sheet 5 , and an outer sheath 6 .

[0057] (direction definition)

[0058] Here, in this embodiment, the inner sheath 3 , the reinforcing sheet 5 , and the outer sheath 6 are formed in a cylindrical shape having a common central axis O.

[0059] In this embodiment, the direction along the central axis O is referred to as the longitudinal direction. In addition, a section perpendicular to the longitudinal direction is referred to as a transverse section, and a section along the longitudinal direction is r...

no. 2 Embodiment approach

[0112] Next, a second embodiment of the present invention will be described, but the basic configuration is the same as that of the first embodiment. Therefore, the same reference numerals are assigned to the same configurations, their descriptions are omitted, and only different points will be described.

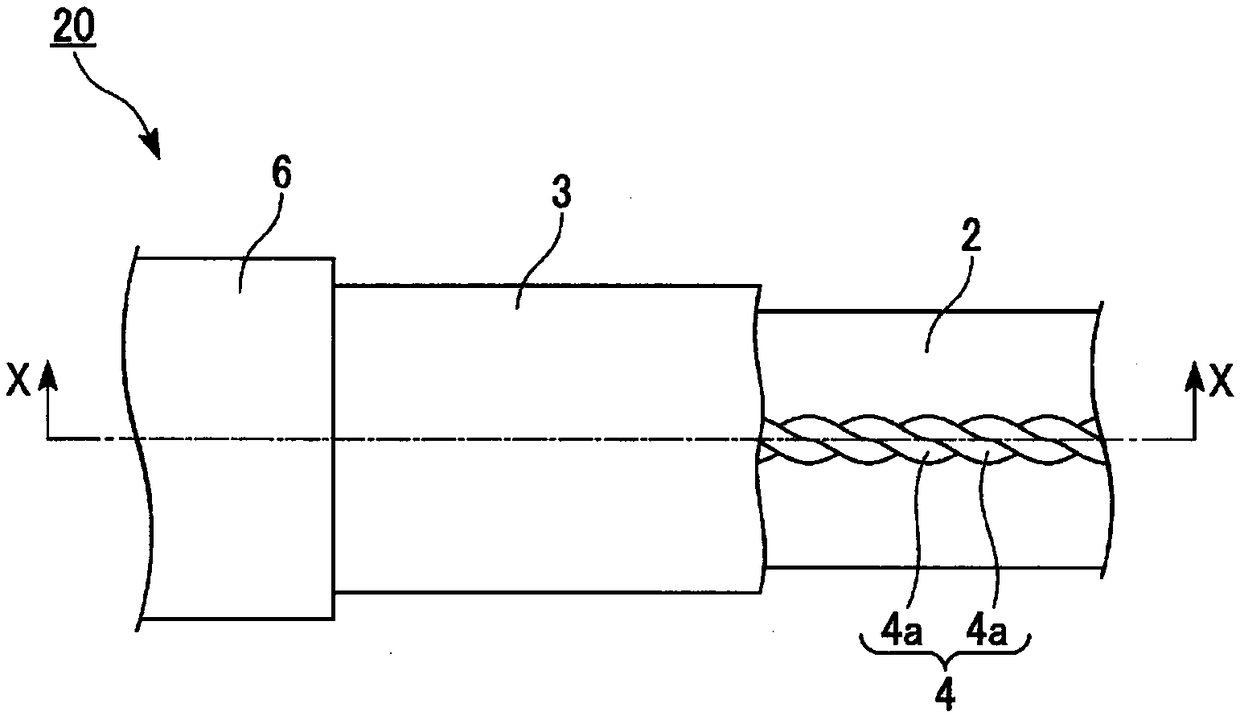

[0113] Such as Figure 3A , Figure 3B As shown, the optical fiber cable 20 of the second embodiment differs from the first embodiment in the form of the strip body 4 and the inner sheath 3 .

[0114] The thread body 4 of the second embodiment is formed of a yarn (yarn: yarn) twisted with fibers such as PP and polyester. exist Figure 3A , Figure 3B In the example shown, the linear body 4 is formed by further twisting a plurality of plain yarns 4a which are yarns. also, Figure 3A It is an explanatory diagram showing the structure of the optical fiber cable 20 according to the second embodiment, and the illustration of each structure is partially omitted. Specifical...

no. 3 Embodiment approach

[0125] Next, a third embodiment of the present invention will be described, but the basic configuration is the same as that of the first embodiment. Therefore, the same reference numerals are assigned to the same configurations, their descriptions are omitted, and only the differences will be described.

[0126] Figure 5 The optical fiber cable 30 of the third embodiment shown differs from the first embodiment in that the linear body 4 is fixed to the reinforcement sheet 5 .

[0127] Such as Figure 5 As shown, the line body 4 of the third embodiment is fixed to the reinforcing sheet 5 via the fixing portion 8 and the fixing layer 9 . The fixing portion 8 is formed of, for example, an adhesive. The fixing layer 9 is formed by attaching, for example, a PET sheet to the inner peripheral surface of the reinforcing sheet 5 with an adhesive. The fixing layer 9 is formed over the entirety of the inner peripheral surface of the reinforcing sheet 5 . Thereby, for example, even w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com