High-temperature steam-type self-cleaning oven

A high-temperature steam, self-cleaning technology, applied in the field of ovens, can solve the problems of inconvenient wiping, fouling and mildew in the inner liner, and endangering health, and achieve the effect of decomposing oil stains and preventing mildew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

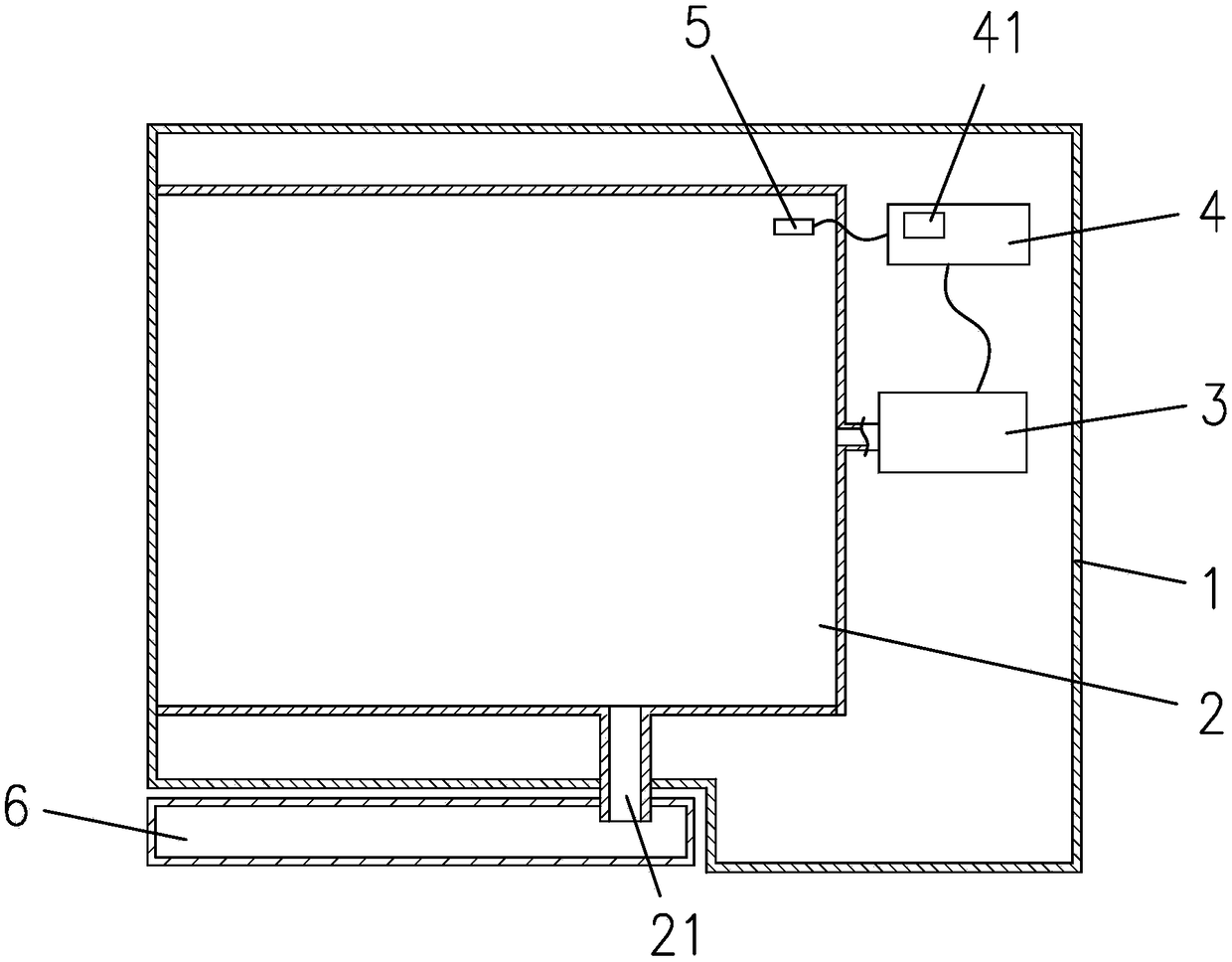

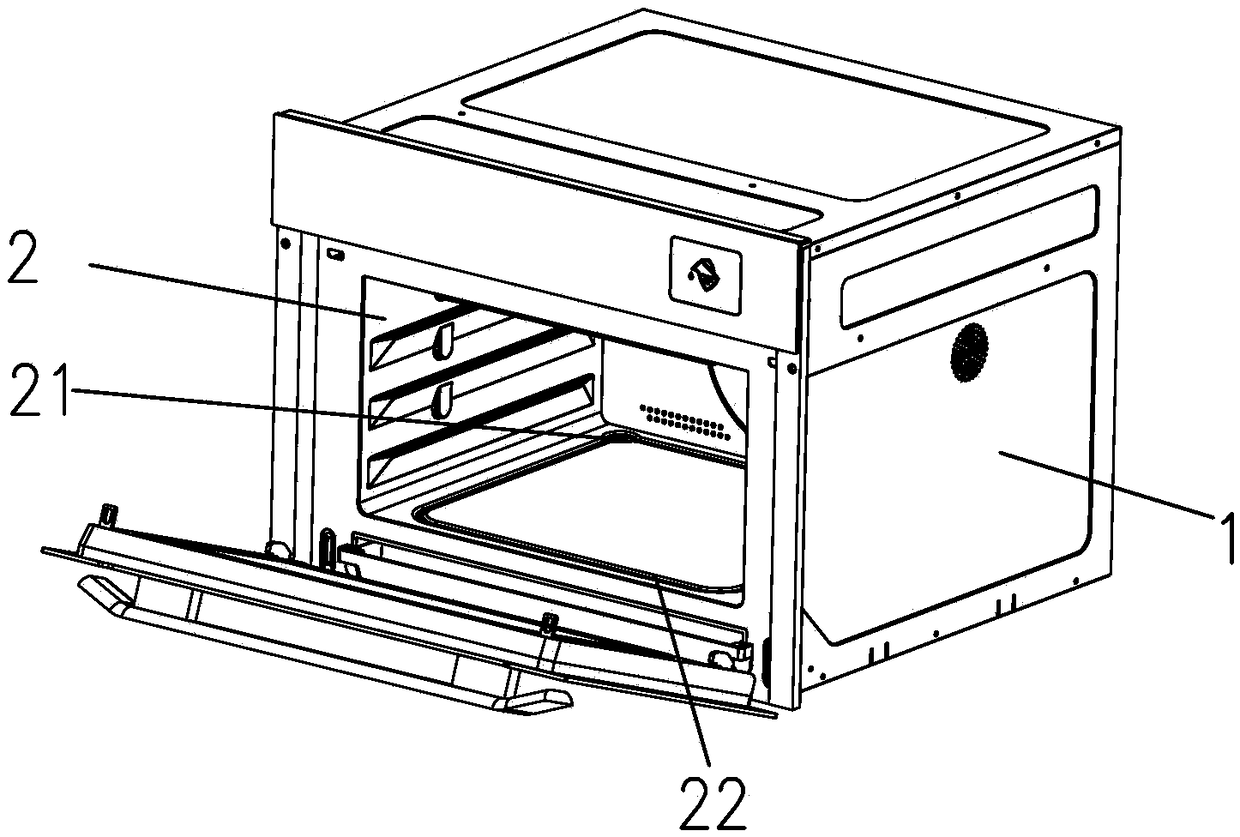

[0016] refer to figure 1 , a high-temperature steam-type self-cleaning oven, including a box body 1 and an inner container 2, a steam generating device 3 and a controller 4 are arranged between the box body 1 and the inner container 2; Connection; the steam output end of the steam generating device 3 is connected to the inner tank 2; the controller 4 controls the steam generating device 3 to deliver high-temperature steam to the inner tank 2 after receiving the self-cleaning instruction. The self-cleaning command may be a "self-cleaning" button set on the oven control panel, which is turned on by the user according to the needs of use, so as to realize the self-cleaning program of the inner container.

[0017] The steam generator 3 in the oven can clean and heat the liner 2 with high-frequency and large steam volume, and use high temperature to decompose oil stains; at the same time, the internal humidity is high, which can soften the attachments on the wall of the liner 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com