Space five-freedom-degree motion heavy-load trolley docking platform

A technology of docking platform and degree of freedom, applied in the direction of workbench, workshop equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive operators, the number of operators, technical experience, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

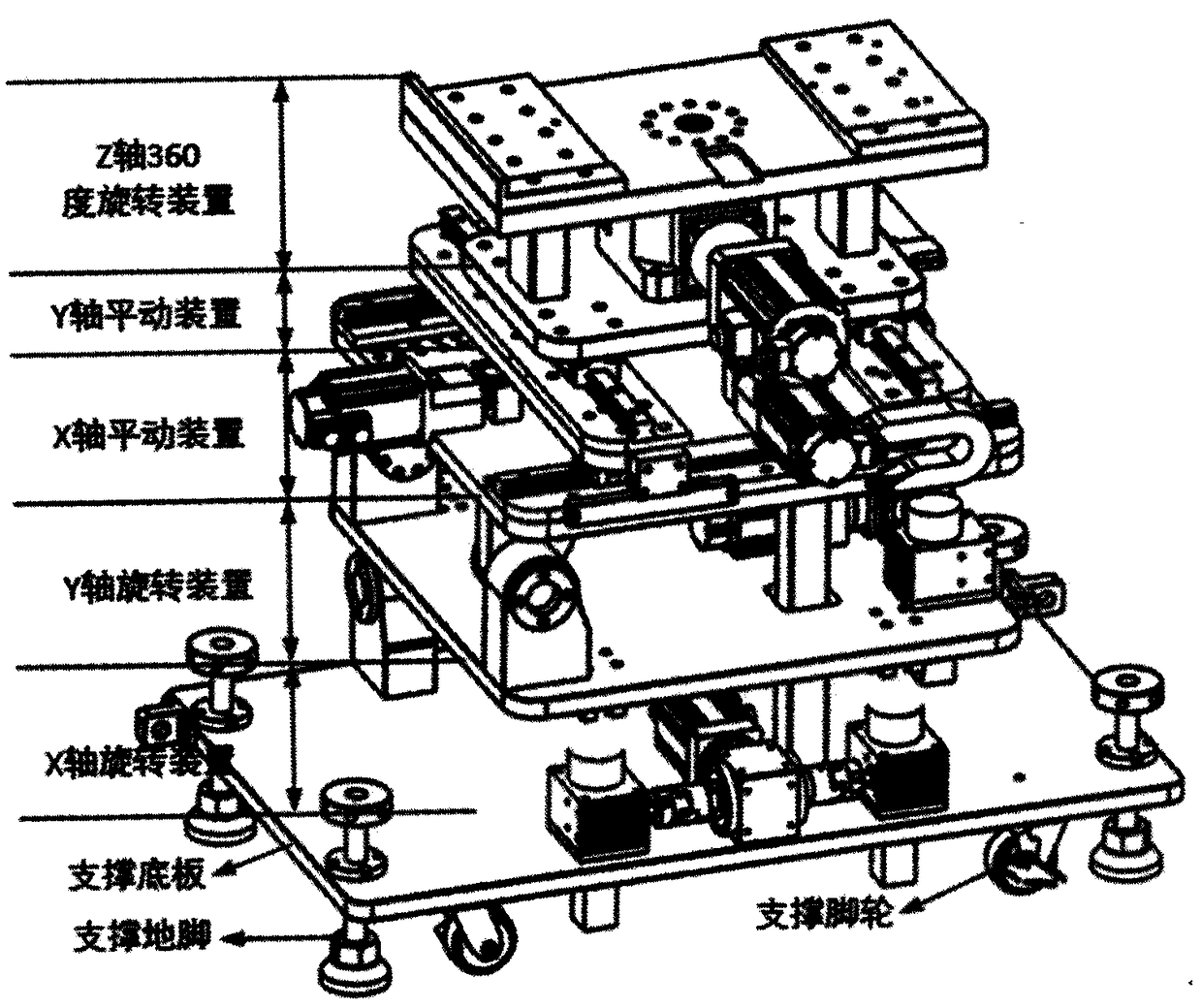

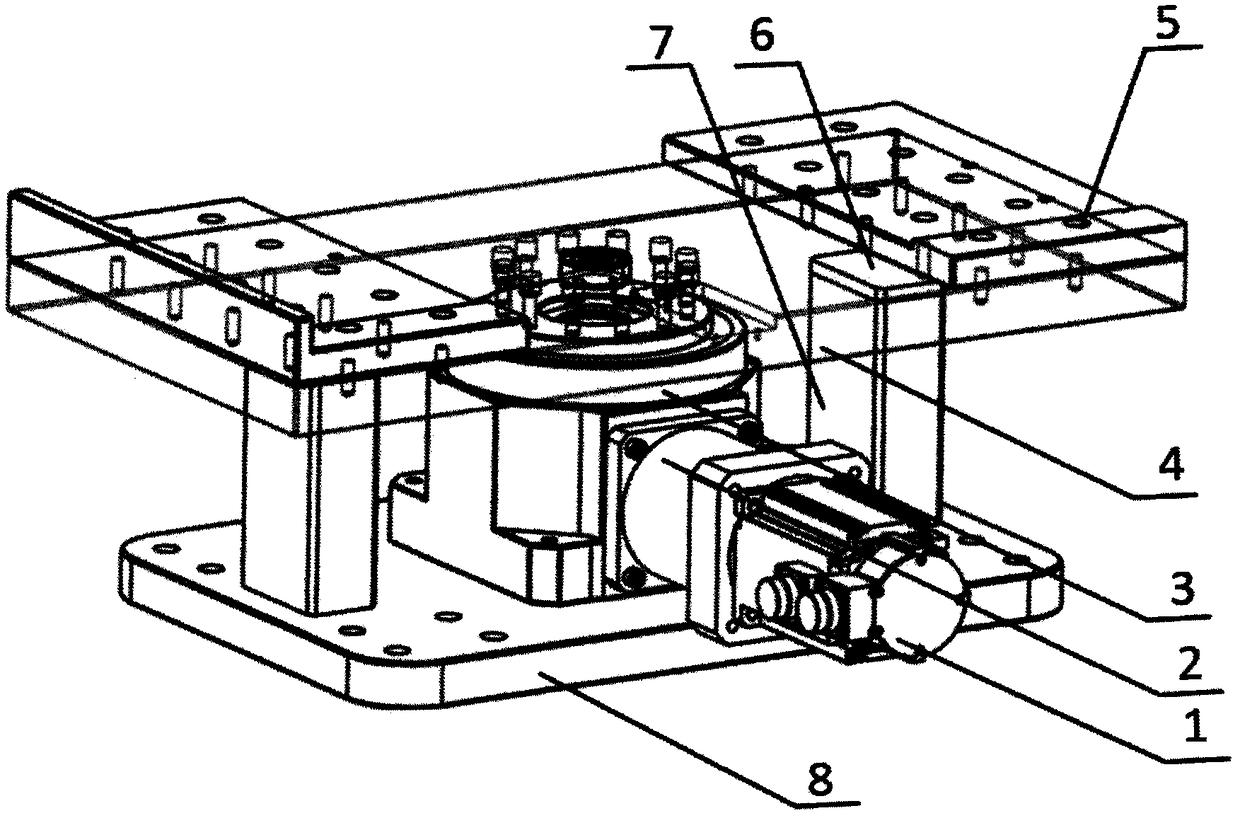

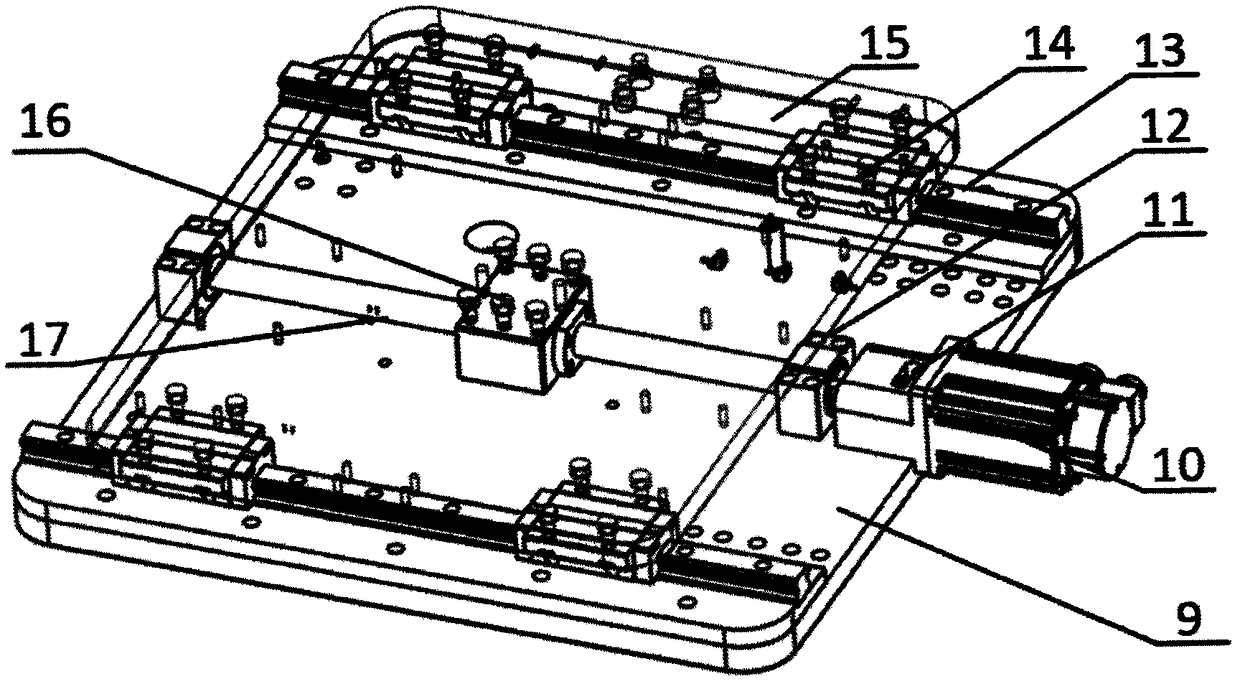

[0017] A space five-degree-of-freedom movement heavy-duty trolley docking platform, such as figure 1 As shown, it includes a Z-axis 360-degree rotating device, a Y-axis translation device, an X-axis translation device, a Y-axis rotation device and an X-axis rotation device, and a support base plate, support feet and support casters installed at the bottom of the trolley. The Z-axis 360-degree rotation device is located on the top of the docking platform, which can realize the 360-degree rotation of the module, thereby adjusting the gap between the two sides of the docking module. The Y-axis translation device and the X-axis translation device are located under the Z-axis 360-degree rotation device, which can realize the front-back and left-right movements of the docking module. The Y-axis rotation device and the X-axis rotation device can realize the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com