Detection device and detection method for blocking of fused deposition type 3D printing machine spray head

A 3D printer and blockage detection technology, applied in the field of 3D printing, can solve the problems of limited printing materials, unsuitable promotion, narrow application range, etc., and achieve the effects of preventing mechanical structure damage, easy promotion, and preventing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

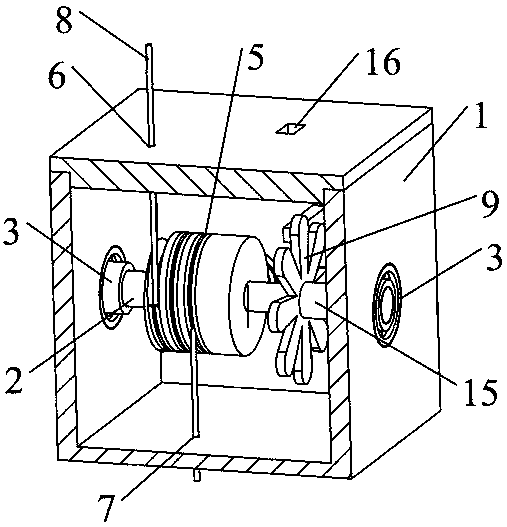

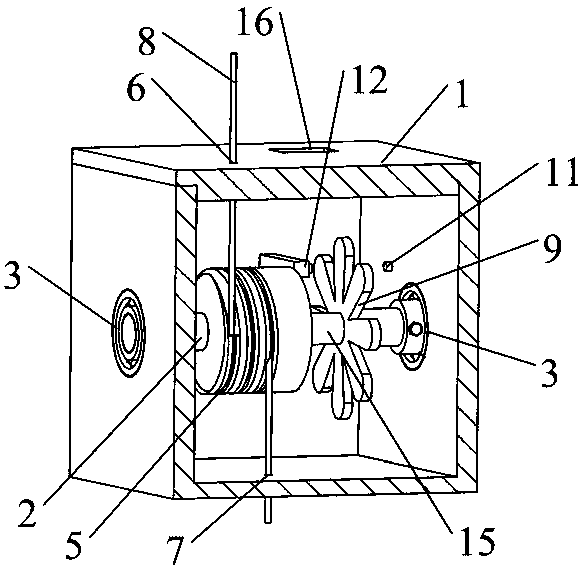

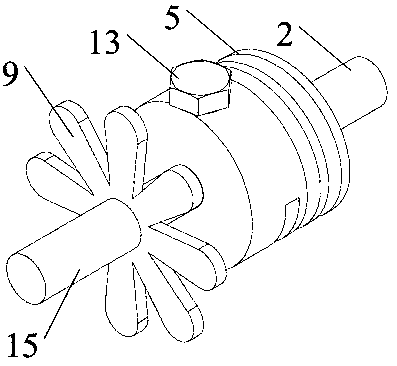

[0051] The invention provides a fused deposition type 3D printer nozzle clogging detection device, such as Figures 1 to 7 As shown, it includes: a box body 1, and the inside of the box body 1 is provided with a worm 2 and a fan blade assembly;

[0052] The first end of the worm 2 is rotationally connected with the box wall;

[0053] The fan blade assembly is provided with a fan blade rod 15, and the fan blade rod 15 is covered with a fan blade 9;

[0054] The first end of the blade rod 15 is rotatably connected with the box wall;

[0055] The second end of the blade rod 15 is connected to the second end of the worm, and the blade rod 15 rotates synchronously with the worm 2 and drives the blade 9 to rotate;

[0056] The first side of the fan blade 9 is provided with a first photoelectric through-beam sensor 11;

[0057] The second side of the fan blade 9 is provided with a second photoelectric sensor 12;

[0058] The first photoelectric through-beam sensor 11 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com