Mobile platform truck

A technology for platform vehicles and electric vehicles, applied in the field of mobile platform vehicles, can solve the problems of many people required, time-consuming, inability to adapt to loading and unloading operations, etc., and achieve the effect of safe and reliable driving and stable lifting action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

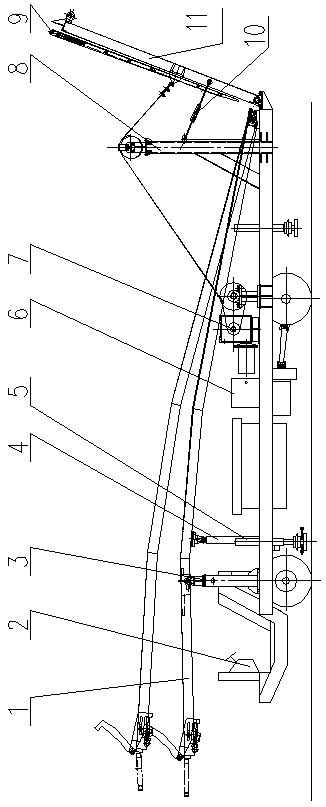

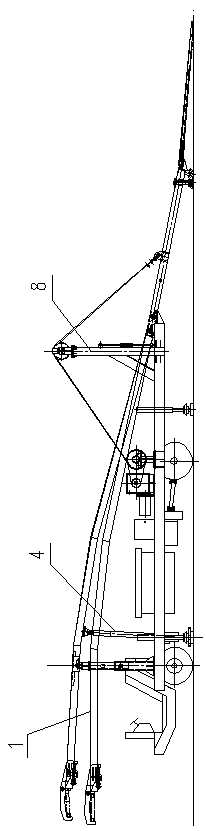

[0028] A mobile station trolley, comprising: a front lifting platform composition 1, the front lifting platform composition 1 is connected to a front platform lifting device composition 4 and a telescopic bracket composition 3, the front platform lifting device composition 4 and a telescopic The support components 3 are respectively connected to the special electric vehicles 2, the rear end of the special electric vehicles 2 is connected to the rear lifting platform component 11, the rear lifting platform component 11 is connected to two movable bridge components 9, and the rear lifting platform component 11 passes through pulleys The bracket composition 8 is connected with the rear platform lifting device 7, the pulley bracket composition 8 is equipped with a fixing rod composition 10, and its lower part is connected with a special electric vehicle 2, and the special electric vehicle 2 is equipped with 4 sets of manual adjustment support devices 5 .

Embodiment 2

[0030] The mobile station trolley, the front lifting platform component 1 can swing up and down along the rear end shaft, the lifting speed is 90mm / min, and the maximum stroke is 550mm, which can realize the docking with the horizontal position and the middle position of the special transport vehicle for double-decker cars , to complete the double-station loading and unloading of vehicles on the second floor;

[0031] For the mobile station trolley, the rear lifting platform composition 11 adopts a chain wheel and a drum wire rope transmission mode, the drum diameter is Φ200mm, the wire rope diameter is Φ8mm, the lifting speed is 1400mm / min, and the stroke is 1135mm;

[0032] The special-purpose electric vehicle can carry 5 tons, the empty vehicle load-bearing surface height is 560mm, the total length of the vehicle is 6510mm, the vehicle width is 2940mm, the front overhang length of the vehicle is 1300mm, the rear overhang length is 2210mm, and the climbing angle is not more t...

Embodiment 3

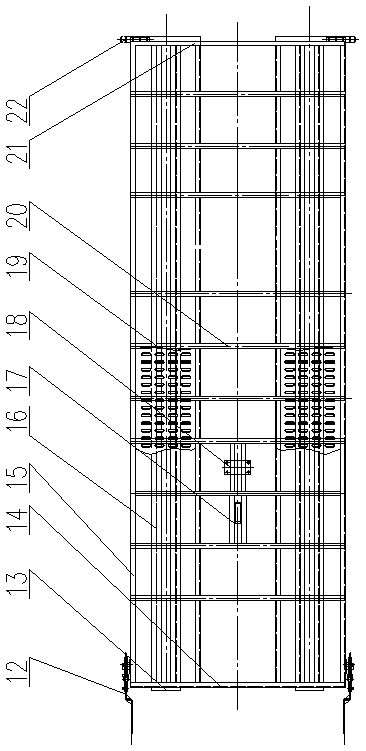

[0034] According to the mobile station trolley described in embodiment 1 or 2, the front lifting platform composition 1 includes four H-shaped steel longitudinal beams A16 and two channel steel side beams A15, each of the longitudinal beams A16, the The side beams A15 are composed of three sections, and the angle between each section is not more than 6°. The longitudinal beams A16 and the side beams A16 are connected to several beams A20, and the front lifting platform is composed of 1 The side beam A15, the longitudinal beam A16, and the crossbeam A20 are covered with an oblong hole anti-skid steel plate A19 with raised edges, and the front end of the side beam A15 is connected with a swing hook and a locking mechanism 12 , the front beam 14 is connected to the buffer pad 13, the rear beam 21 is connected to the rotating shaft to form A22, and the rotating shaft A is connected to the bearing seat A, and the bearing seat A is connected to the special electric vehicle 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com