Forklift steering system

A steering system and forklift technology, applied in the field of vehicle steering systems, can solve problems such as large steering space, poor sightlines, and ignorance, and achieve the effects of large directional change range, flexible directional change, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

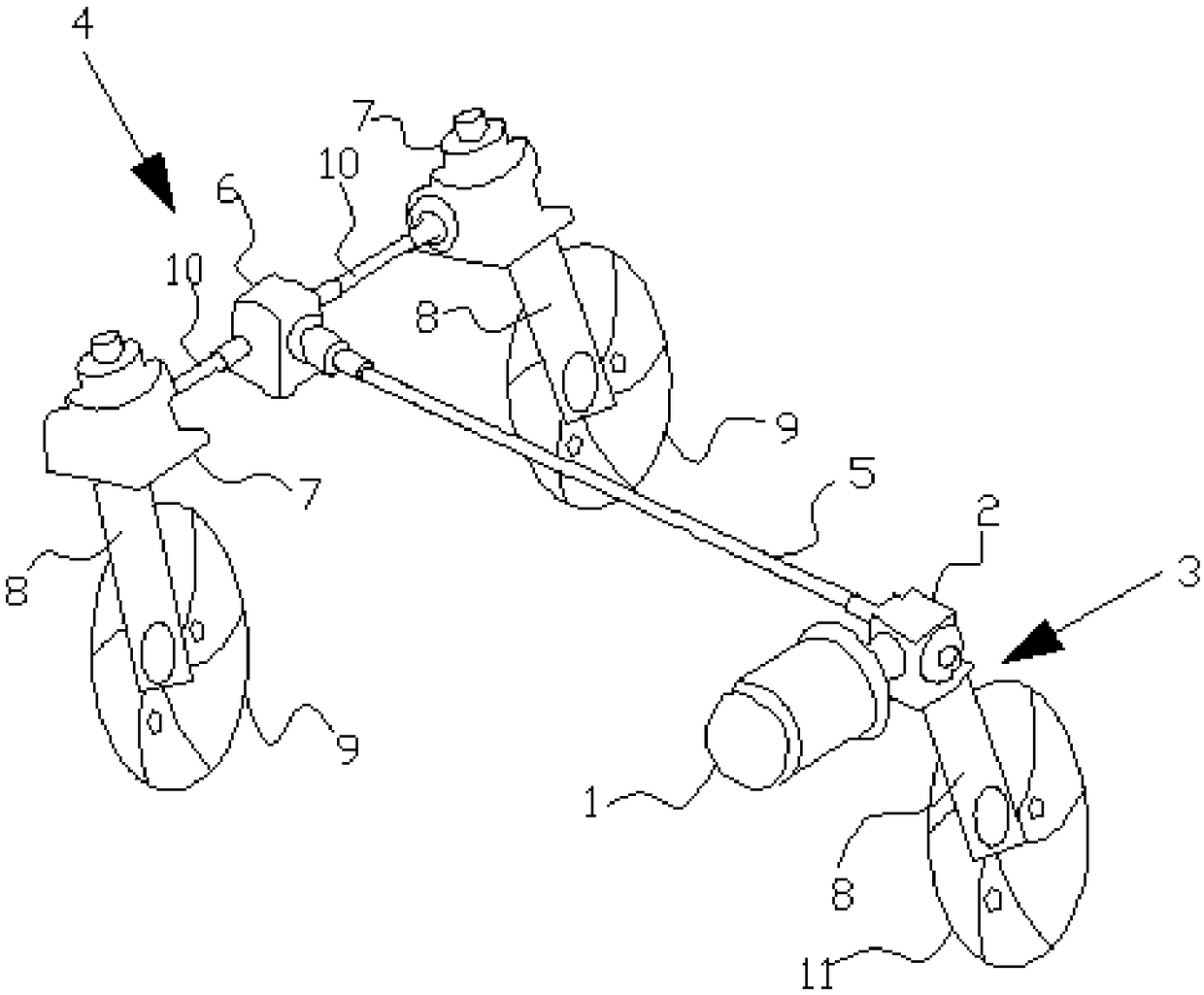

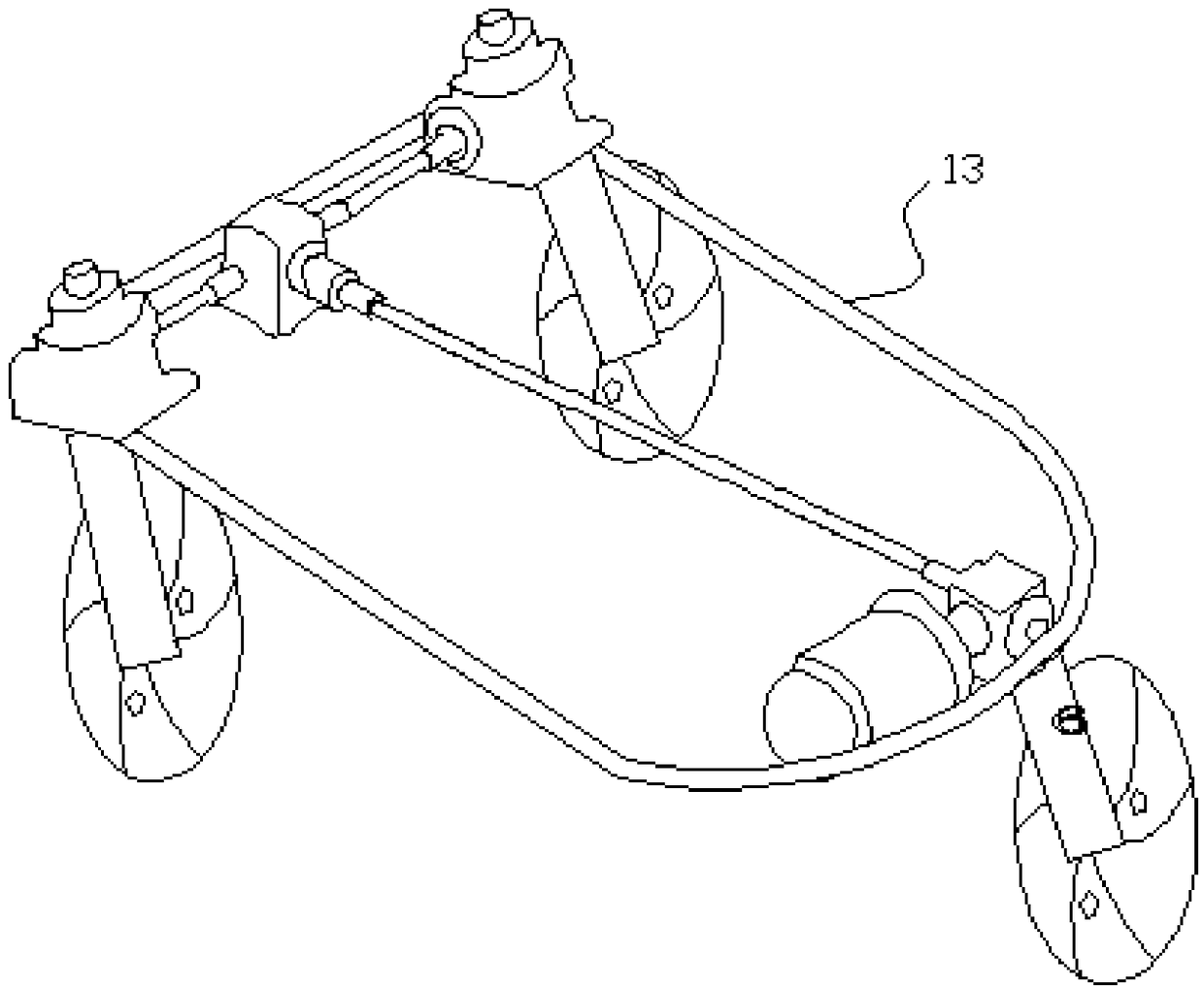

[0021] Example 1: A steering system of a forklift, such as figure 1 As shown, it includes a motor 1, a reducer 2, a front steering unit 3, and a rear steering unit 4. The output shaft of the motor is connected to the input shaft of the reducer. The reducer has dual output shafts, one of which is Connected to the front steering unit, and another output shaft connected to the rear steering unit;

[0022] The rear steering unit includes a first transmission shaft 5, two transmission shafts 10, a commutator 6, two transmissions 7, two pillar plates 8 and two rear wheels 9. One end of the first transmission shaft is connected to the One output shaft of the reducer is connected, and the other end of the first transmission shaft is connected to the input shaft of the commutator, and the commutator has parallel dual output shafts, and is connected to the side transmission shafts respectively. One end of the side drive shaft is connected to the input shaft of the transmission, the output ...

Embodiment 2

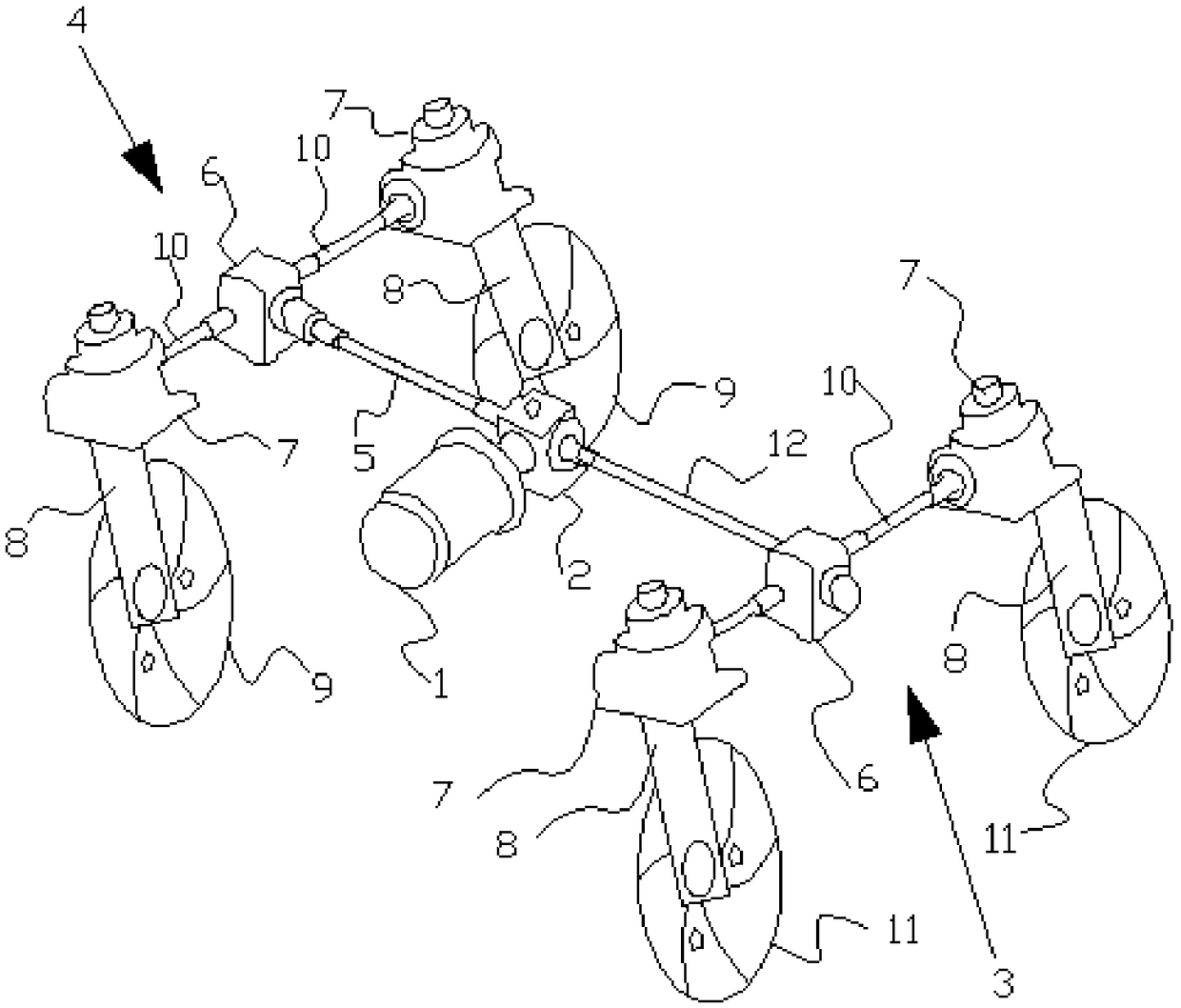

[0028] Embodiment 2: A steering system of a forklift, such as image 3 As shown, it has a similar structure to Embodiment 1, except that the front steering unit includes a second drive shaft 12, two side drive shafts 10, a commutator, two drives, two upright plates and two For the front wheel, one end of the second transmission shaft is connected with an output shaft of the reducer, and the other end of the second transmission shaft is connected with the input shaft of the commutator, and the commutator has a parallel The dual output shafts are respectively connected to one end of the side transmission shaft, the other end of the side transmission shaft is connected to the input shaft of the transmission, and the output shaft of the transmission is connected to the upper end of the column plate , The lower end of each column plate is connected with the front wheel, the torque of the motor is transmitted to the second drive shaft through the reducer, and the direction is changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com