Mining hydraulic power operation machine

A working machine and hydraulic technology, which is applied to drilling with liquid/gas jets, producing fluids, drilling equipment, etc., can solve problems such as difficulty in adapting to underground applications, inability to meet the needs of drilling holes, and large floor space, achieving structural The effect of compactness, small footprint and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

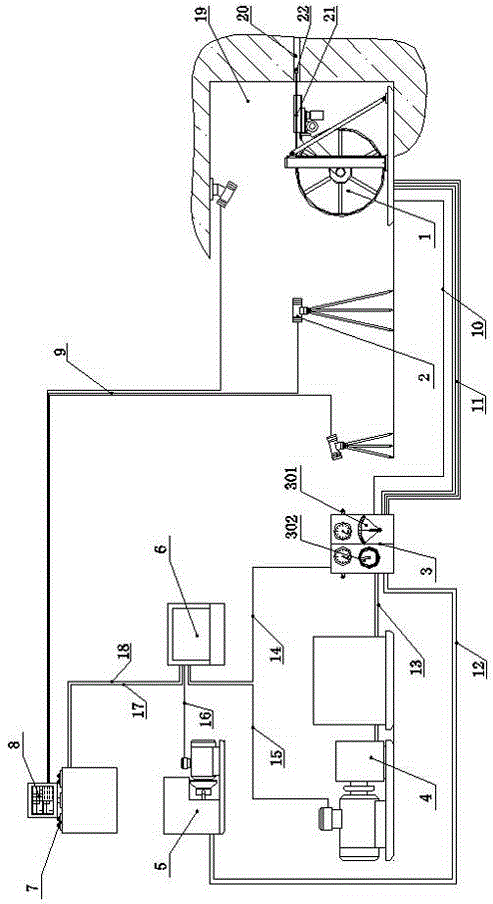

[0038] Such as figure 1 The mine hydraulic work machine shown includes a main engine 1, an executive platform 3, a clean water pump station 4, a hydraulic pump station 5 and a switch cabinet 6, the executive platform 3 passes a power cable 14, and the clean water pump station 4 passes a power cable 15, hydraulic pressure The pump stations 5 are electrically connected to the switch cabinets 6 respectively through power cables 16 . A flexible steel pipe remote controller 301 and a high-pressure water remote controller 302 are installed in the executive platform 3, and the host 1 is connected to the flexible steel pipe remote controller 301 through multiple oil pipes 11, and connected to the high-pressure water remote controller 302 through water pipes 10 , on the other side of the execution platform 3, the hydraulic pump station 5 is connected with the flexible steel pipe remote controller 301 and the oil pressure gauge through two oil pipes 12, and the clean water pump station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com