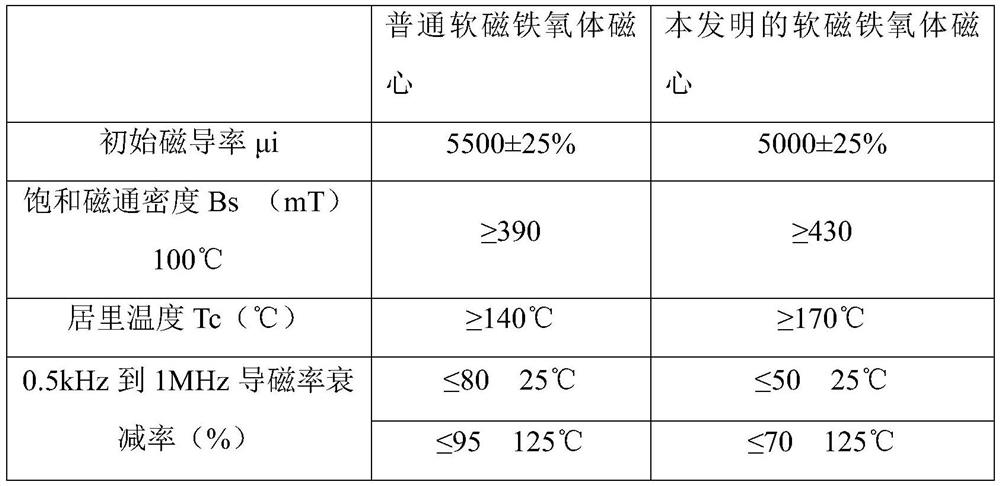

A kind of preparation method of manganese zinc soft magnetic ferrite material with four high characteristics

A manganese-zinc soft magnet, characteristic technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic core manufacturing, inorganic material magnetism, etc., can solve the problems of high magnetic permeability, difficult to achieve the most satisfactory, etc., to achieve high magnetic permeability, Good spectral stability and high sintering density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a four-high-characteristic manganese-zinc soft ferrite material, comprising the following steps:

[0026] (1) Ingredients: take Fe 2 o 3 , MnO and ZnO with the main ingredients, the molar ratio is (51.5-52.5): (30.5-31.5): (16.5-17.5);

[0027] (2) Matching auxiliary materials: ZrO equivalent to 0.005-0.010wt% of the main material 2 , 0.006-0.012wt% Nb 2 o 5 , 0.013-0.018wt% CaCO 3 , 0.005-0.001wt% SiO 2 , 0.035-0.05wt% SnO 2 ;

[0028] (3) Pre-burning: Add appropriate amount of deionized water to the main ingredients prepared in step (1), fully mix and stir, then use gadolinium chip machine to make 2-4mm thick blanks, and pre-fire, the pre-burning temperature is 870 -920℃, pre-burning time is 1-2 hours;

[0029] (4) Superfine grinding of auxiliary materials: the auxiliary materials prepared in step (2) except SiO 2 In addition, add an appropriate amount of deionized water, carry out ball milling of auxiliary materials, and add SiO2 whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com