Oil pool provided with separating device

A separation device and oil pool technology, applied in the direction of recovering fat oil/fatty acid from waste, recycling technology, producing fat, etc., can solve the problems of resource waste, environmental pollution, etc., and achieve the effect of effective utilization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

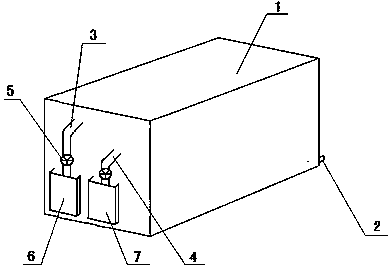

[0009] Combine below figure 1 The present invention is further described.

[0010] An oil pool with a separation device, comprising an oil pool 1 and a water outlet 2, the water outlet 2 is located at the bottom of the oil pool 1, and a neutral oil pipe 3 and a fat gel pipe 4 are also arranged on the side wall of the oil pool 1, The nozzles of the neutral oil pipe 3 and the fat-creating pipe 4 extend into the oil pool 1, the level of the nozzle of the fat-creating pipe 4 is lower than that of the neutral oil pipe 3, and the level of the water outlet 2 is lower than that of the fat-creating pipe 4 The horizontal height of the nozzle.

[0011] The entire separation tank only includes the neutral oil pipe 3, the gelling pipe 4 and the water outlet 2. The structure is simple and no additional power is required. When in use, due to the different densities of the neutral oil, gelatin, and water, due to gravity, after a period of Due to the precipitation of time, the oil pool 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com