Biological fermentation tank with function of rapidly cleaning tank bottom

A bio-fermentation tank, fast technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc., can solve the problem of affecting personal safety, low work efficiency, time-consuming and labor-intensive, etc. problems, to achieve the effect of improving work efficiency, facilitating later maintenance, and rapid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

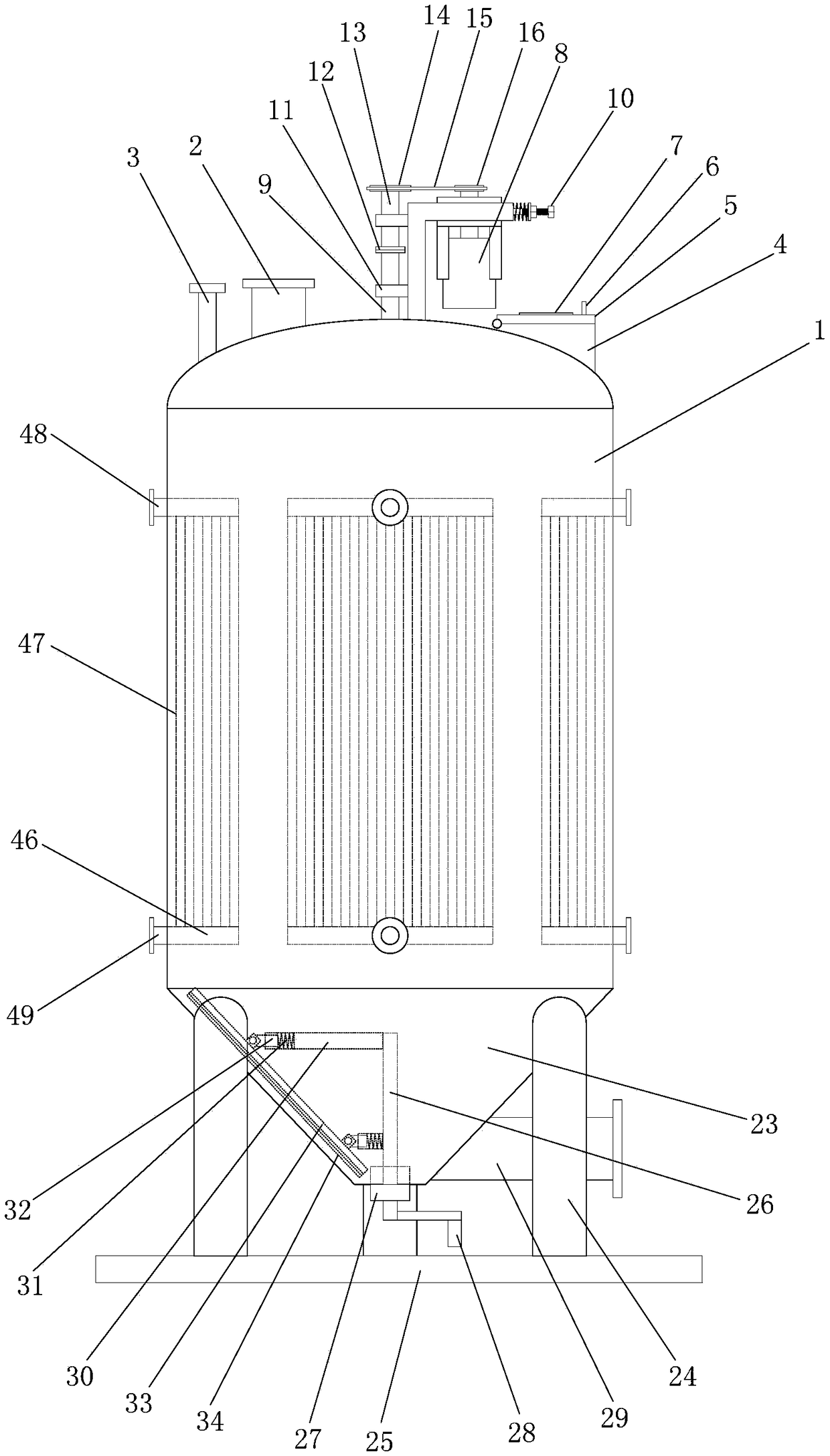

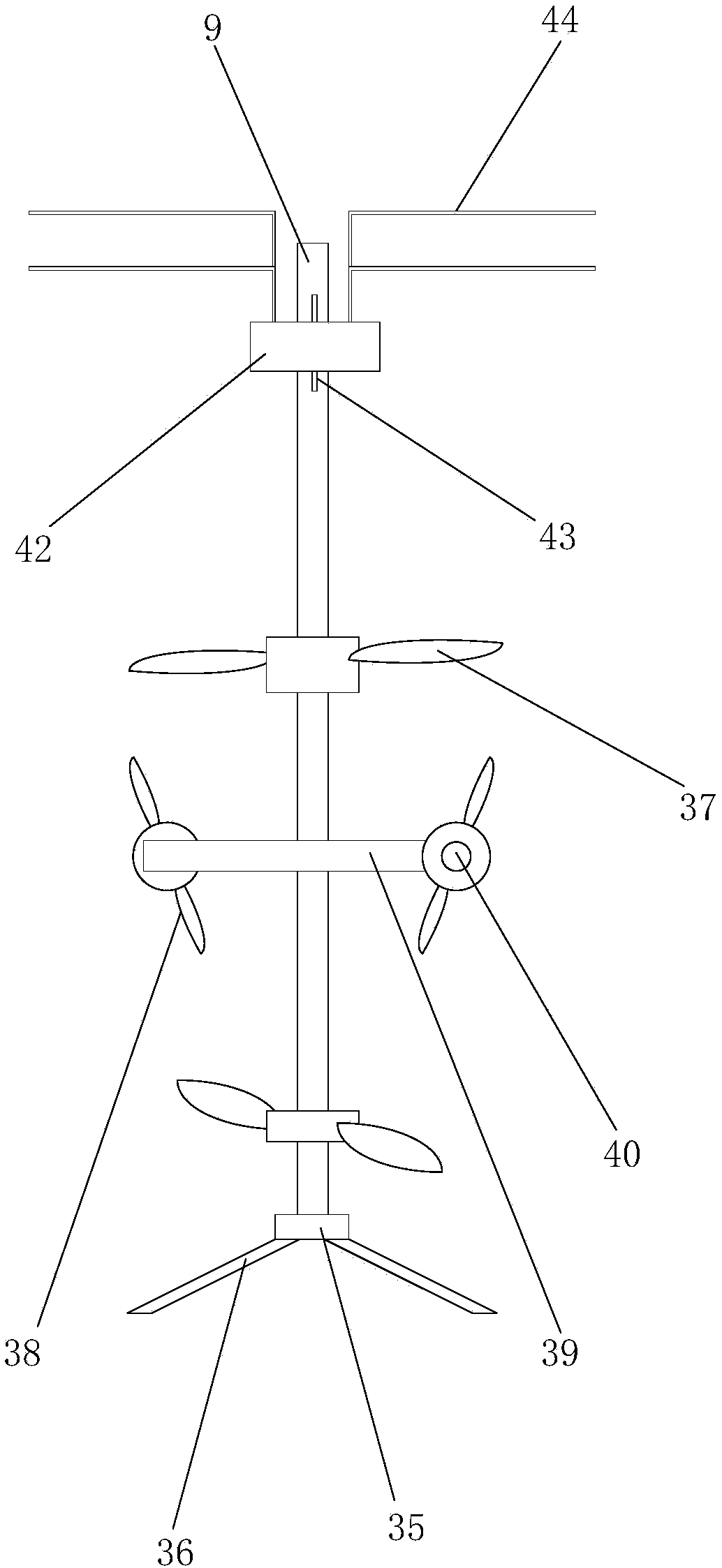

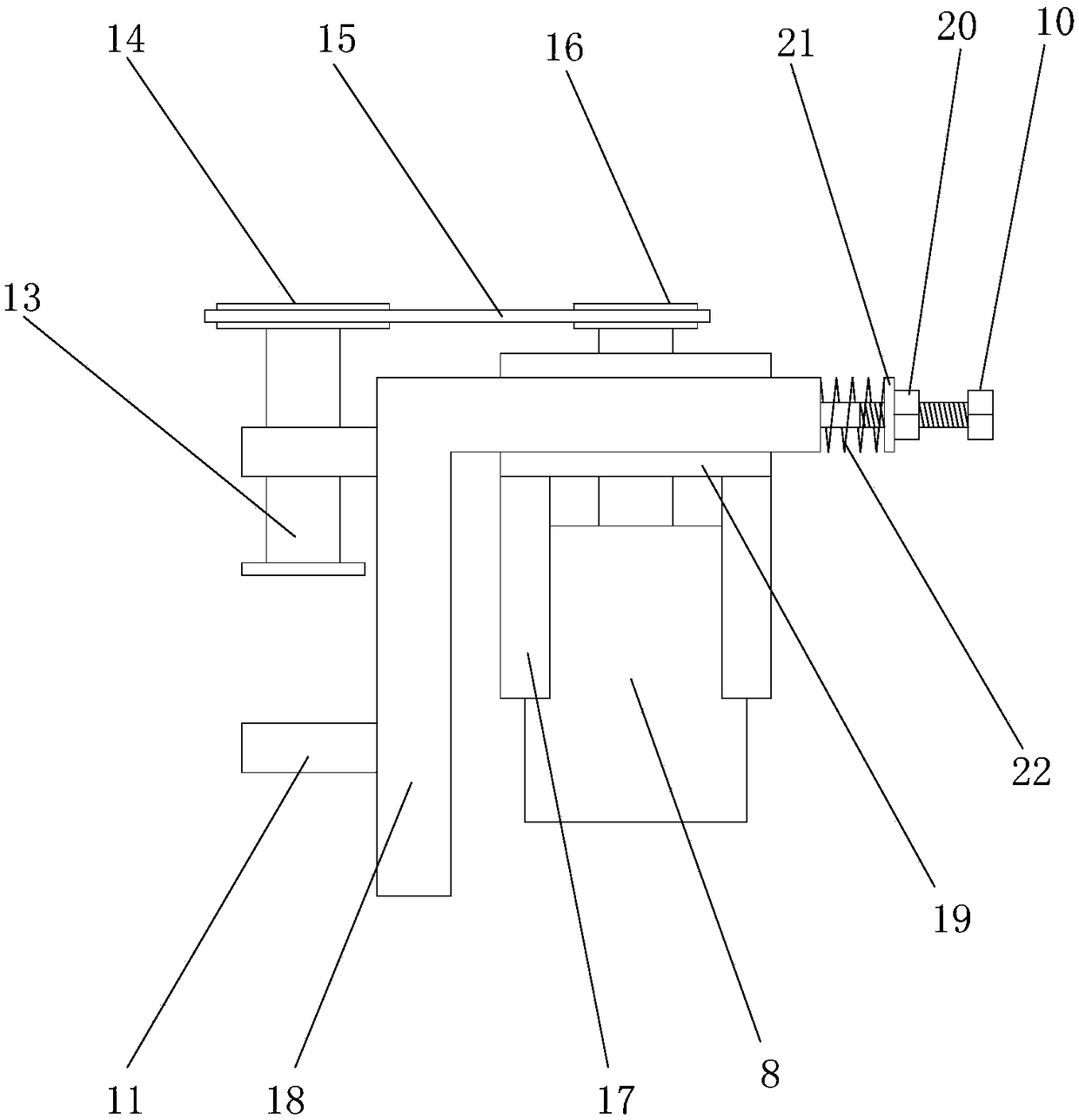

[0016] Such as Figure 1-4 As shown, the tank bottom quick-cleaning biological fermenter disclosed by the present invention includes: a tank body 1, a stirring motor 8, a stirring shaft 9 and an internal heat exchange unit; 3 and the maintenance passage 4; a sealing cover 5 is hingedly installed at the upper opening of the maintenance passage 4, and a glass observation window 7 and a door handle 6 are arranged on the sealing cover 5; the bottom of the tank body 1 is set as an inverted conical bottom 23; Three supporting legs 24 are vertically provided on the outer conical surface of the inverted conical bottom 23; the lower ends of the three supporting legs 24 are fixedly mounted on the same annular base plate 25; A drain pipe 29 communicating with the inside is also provided on the top; a wall-scraping rotating shaft 26 is vertically rotatably installed at the center of the inverted conical bottom 23; the lower end of the scraping rotating shaft 26 runs through the cone top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com