Mixing machine enhanced-granulating device

The technology of a mixer and a mixing drum is applied in the field of raw material processing equipment, which can solve the problems of small wetting area, reduced granulation effect, easy corrosion and rust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

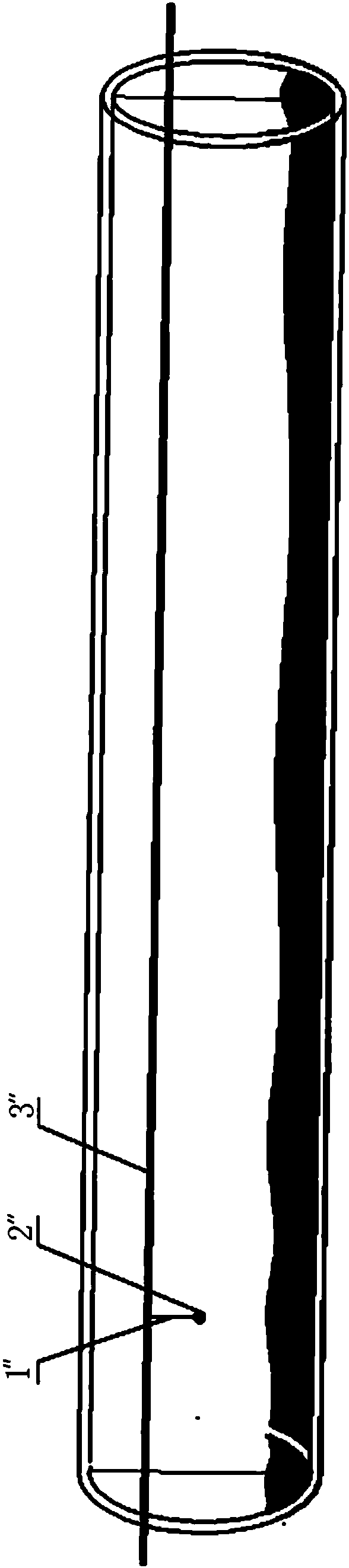

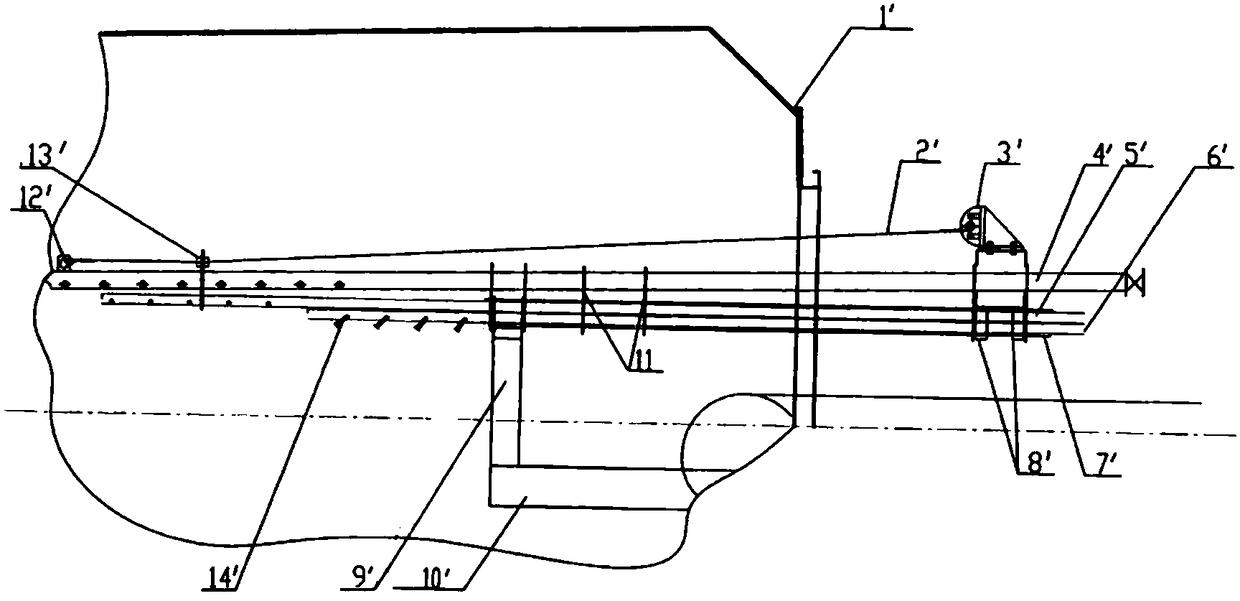

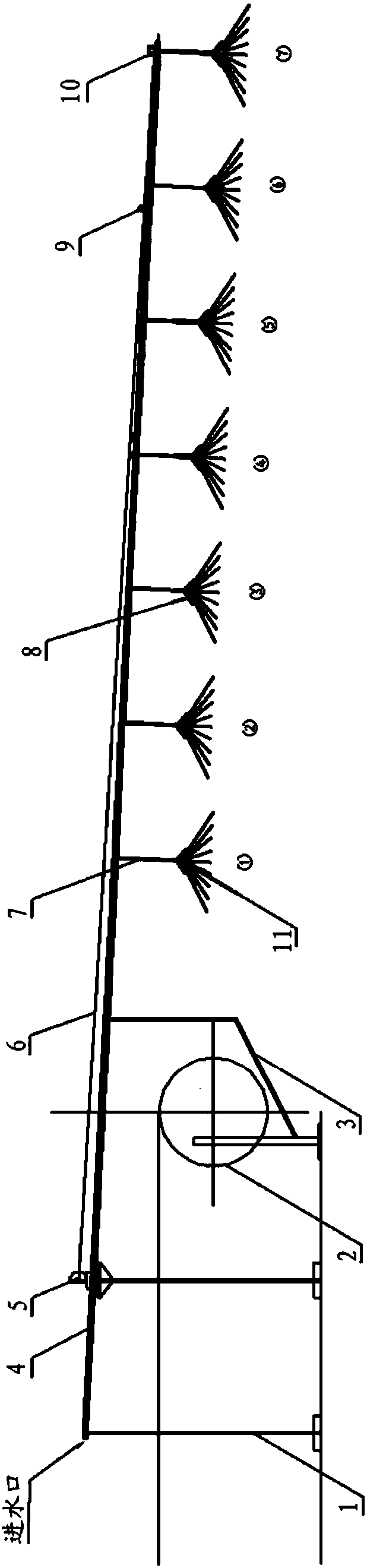

[0041] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0042] In this article, the terms "up, down, inside, and outside" are established based on the positional relationship shown in the drawings. Depending on the drawings, the corresponding positional relationship may also change accordingly. Therefore, it cannot be It is understood as an absolute limitation on the scope of protection; moreover, relational terms such as "first" and "second" are only used to distinguish one component with the same name from another, and do not necessarily require or Imply any such actual relationship or order between these components.

[0043] The air permeability of the sintered material layer is a very important state parameter in the sintering process, which reflects the difficulty of the sintered material ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap