Novel steel bar connecting full-grouting sleeve and construction method thereof

A full grouting and sleeve technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of low construction efficiency and achieve the effect of cheap price, convenient use and simple remedial method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

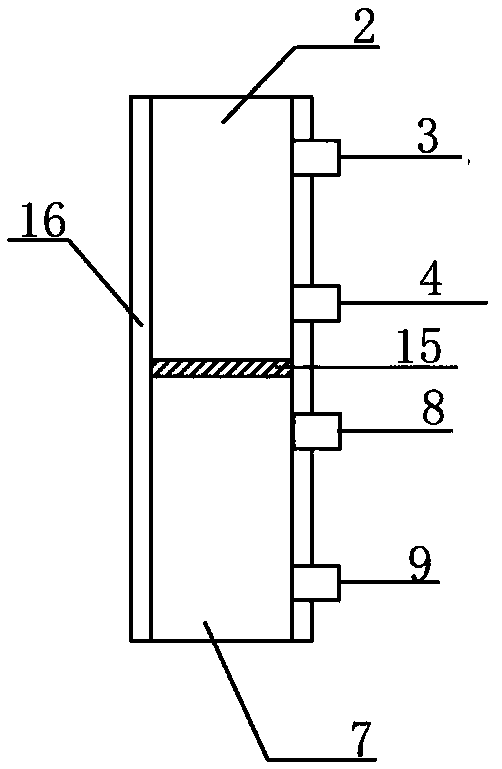

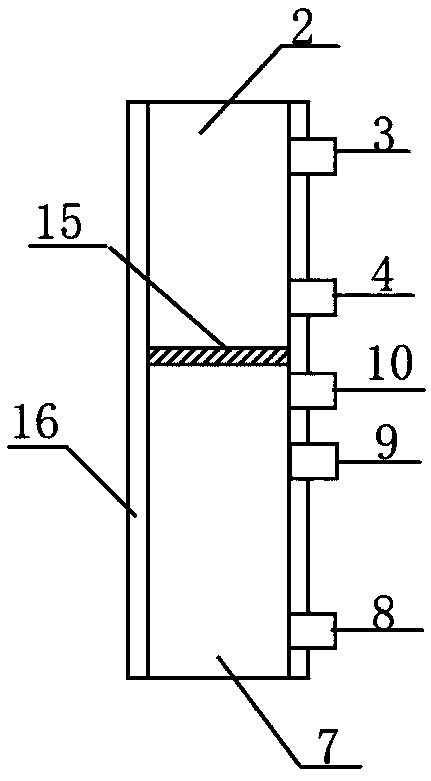

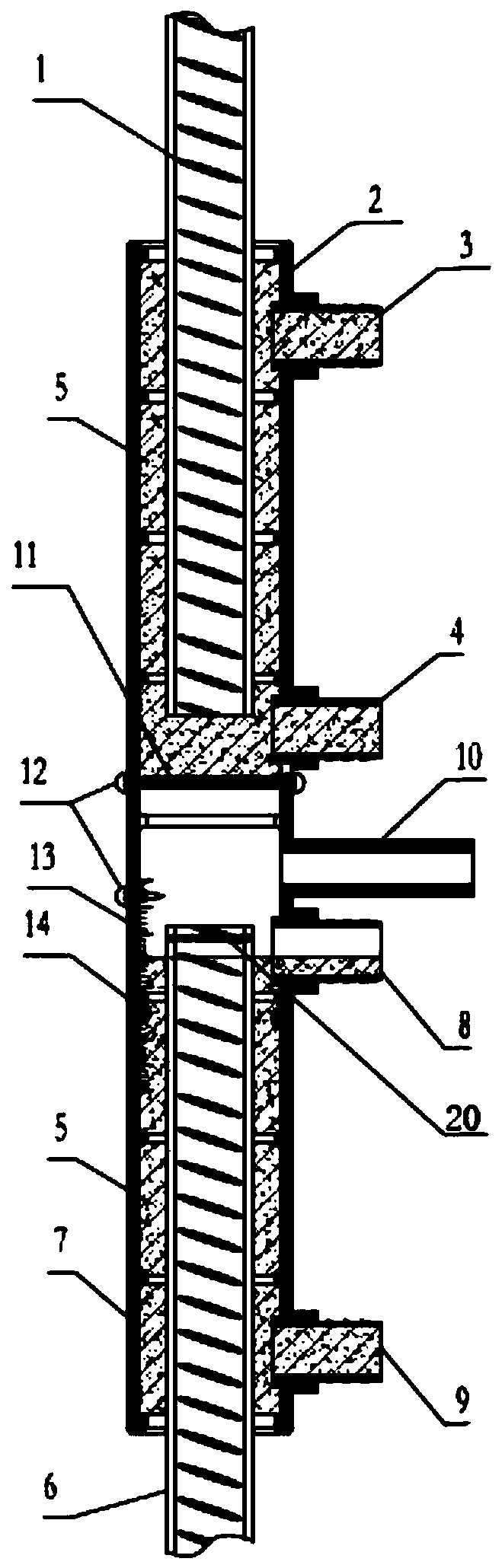

[0034] figure 1 It is a schematic diagram of the basic structure of the new full-grouting connection sleeve. The new full-grouting connection sleeve includes a sleeve body 16 and a partition structure 15. The partition structure 15 is fixed in the sleeve body 16, and it separates the The chamber is divided into a first chamber 2 for accommodating the first steel bar and a second chamber 7 for accommodating the second steel bar and providing detection, and the first chamber 2 is set at a corresponding position on the wall of the sleeve body 16 There are a first hole 3 and a second hole 4 communicating with the first chamber, wherein the first hole 3 is a slurry outlet hole or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com