Method and apparatus for handling piece goods moved one after another in at least one row

A technology for goods and pieces, applied in the field of equipment for pieces of goods, can solve problems such as inaccuracy of pieces of goods, accumulation of wrong positioning of pieces of goods, and deviations from associations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

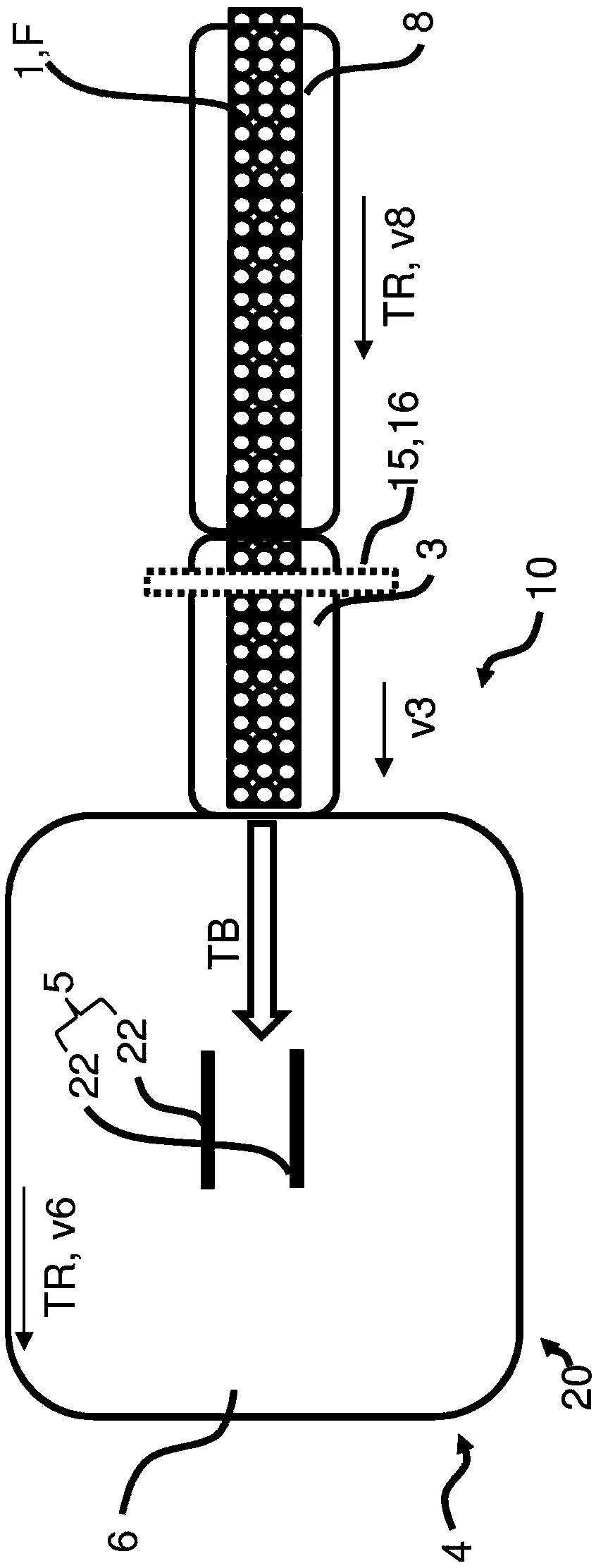

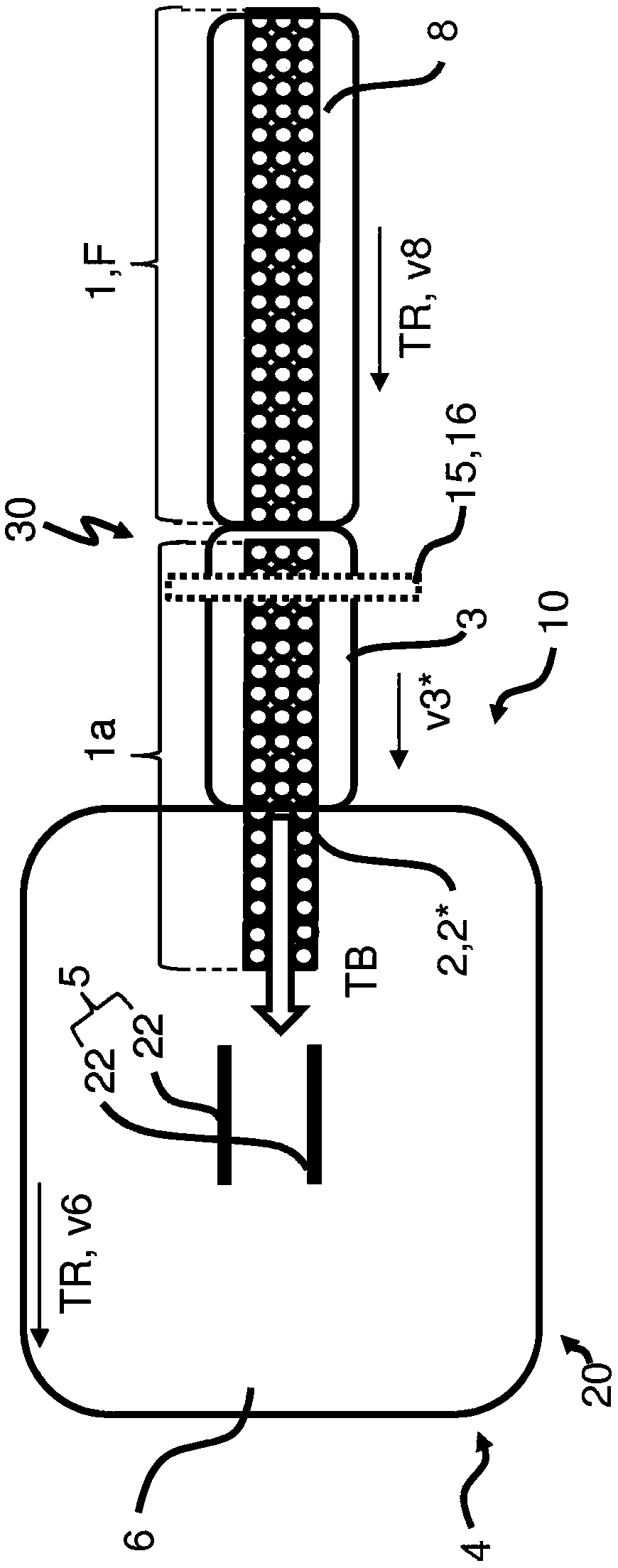

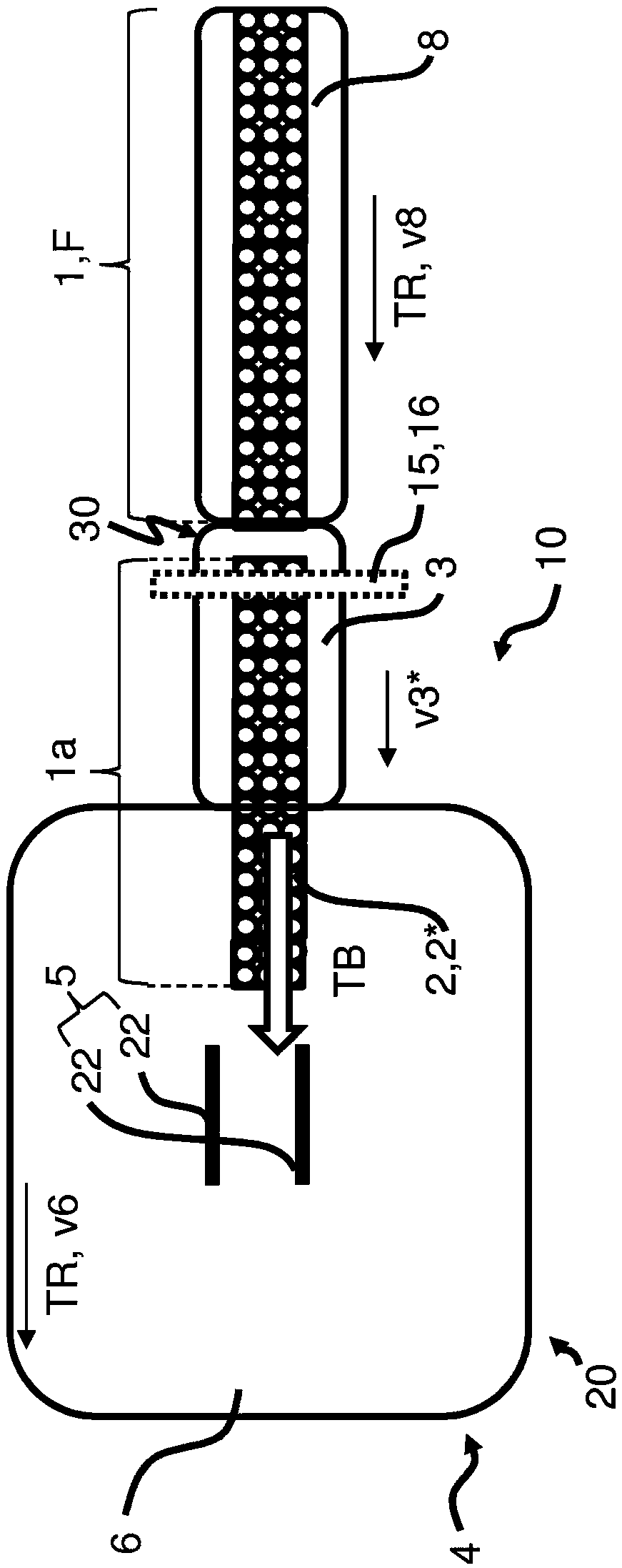

[0051] Figure 1 to Figure 5 The top views each show the time course of an embodiment variant of the method according to the invention for processing successively moving individual goods by means of corresponding handling devices. According to the method description described below, small or minimal gaps or distances between the individual goods 2 may occur during the gap-free conveying of the individual goods 2 moving one after the other. These gaps or distances can arise, for example, through a relative movement of the individual parts 2 relative to one another and / or through dimensional deviations of the individual part parts 2 . When such gaps or distances occur, it can happen that the receiving position of the manipulator 5 or the gripper described below acting in the catch area 4 is no longer correct. If this positioning error of the manipulator 5 with respect to the piece goods 2 to be captured is accumulated by a plurality of piece goods 2 or groups of piece goods 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com