Multi-stage telescoping water outlet pile

A telescopic and telescopic tube technology, applied in watering devices, horticulture, botany equipment and methods, etc., can solve the problems of cumbersome and inconvenient disassembly, maintenance and replacement of parts, reduced sealing performance, etc., to ensure sealing, convenient installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

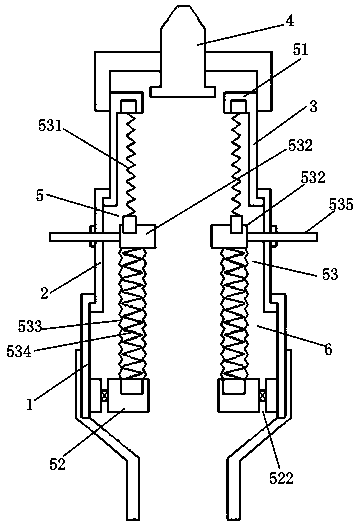

[0027] Such as Figures 1 to 5 As shown, a multi-stage telescopic water discharge pile includes a bottom fixed pipe 1, a top telescopic pipe 3, a top water nozzle 4, a transitional telescopic pipe 2, and a telescopic inner core 5. The bottom fixed pipe 1 and the top telescopic pipe 3 are connected with a plurality of end-to-end telescopically connected transition telescopic pipes 2; the top water nozzle 4 is installed on the upper end of the top telescopic pipe 3; the bottom fixed pipe 1. The transitional telescopic tube 2 and the top telescopic tube 3 are provided with a through connection groove 6 inside; the telescopic inner core 5 is installed in the connection groove 6; the telescopic inner core 5 includes a bottom positioning ring 52 and a telescopic assembly 53 , the top positioning ring 51; the bottom positioning ring 52 is installed around the inside of the bottom fixed pipe 1; the top positioning ring 51 is installed around the upper end of the top telescopic tube 3;...

Embodiment 2

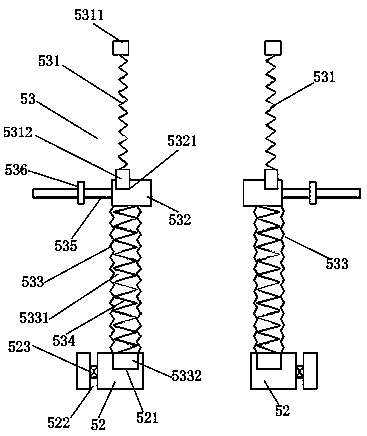

[0030] This embodiment refers to Embodiment 1, the difference is that this embodiment detachably connects the telescopic components to further increase the range of axial telescopic expansion, such as figure 1 and 2 As shown, in order to further increase the range of axial expansion and contraction, the telescopic assembly 53 includes an upper bellows 531, a driving ring 532, and a lower annular bellows 533; the upper end of the upper bellows 531 is connected under the top positioning ring 51 On the end face, the lower end of the upper bellows 531 is connected to the upper end of the driving ring 532; It is connected to the upper end surface of the bottom positioning ring 52 . Further preferred connection method, the upper end of the upper bellows 531 is provided with a first threaded ring 5311, the lower end of the upper bellows 531 is provided with a second threaded ring 5312; the lower end of the top positioning ring 51 is provided with a top threaded groove; The upper en...

Embodiment 3

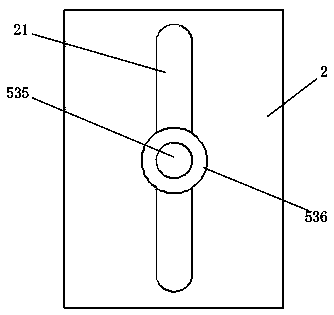

[0034] This embodiment refers to Embodiment 3, the difference is that a plurality of sliding locking screws 535 and a plurality of locking nuts 536 are added, as Figures 1 to 5 As shown, in order to flexibly drive the upper bellows 531 and the lower annular bellows 533 and adjust the water outlet speed, the telescopic assembly 53 also includes a plurality of sliding locking screws 535 and a plurality of locking nuts 536; the driving ring body Around 532, a sliding locking screw 535 is evenly and vertically installed respectively; the surroundings of the transition telescopic tube 2 that is connected to the upper end of the bottom fixed tube 1 are evenly provided with sliding grooves 21, and it is illustrated here that although the present invention only A transitional telescopic tube 2 is shown, but in fact, the present invention can add a plurality of transitional telescopic tubes 2 for upper and lower end-to-end telescopic connections. The sliding groove 21 is formed; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com