Electronic cigarette atomizer

An electronic cigarette atomizer and atomization technology, applied in the field of electronic cigarettes, can solve the problems affecting the normal operation of the heating unit, the atomization seat is easily collapsed and deformed, and the smoke liquid leaks, so as to avoid high temperature ablation failure and avoid smoke liquid leakage. , the effect of large cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

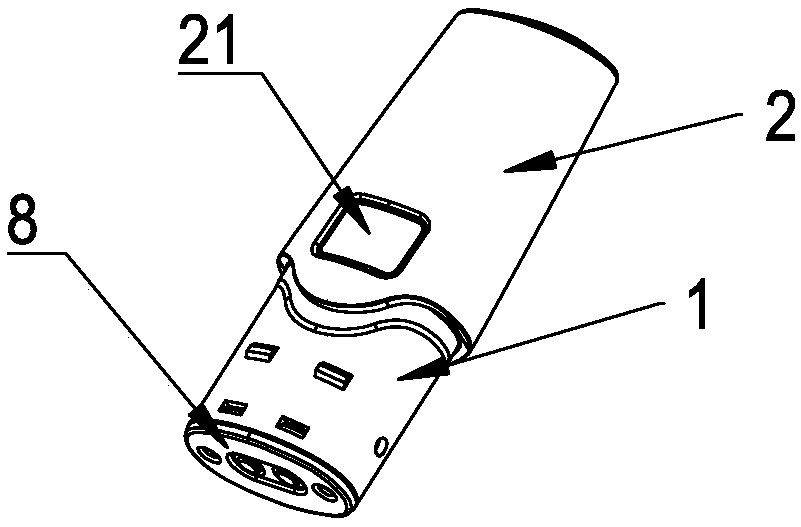

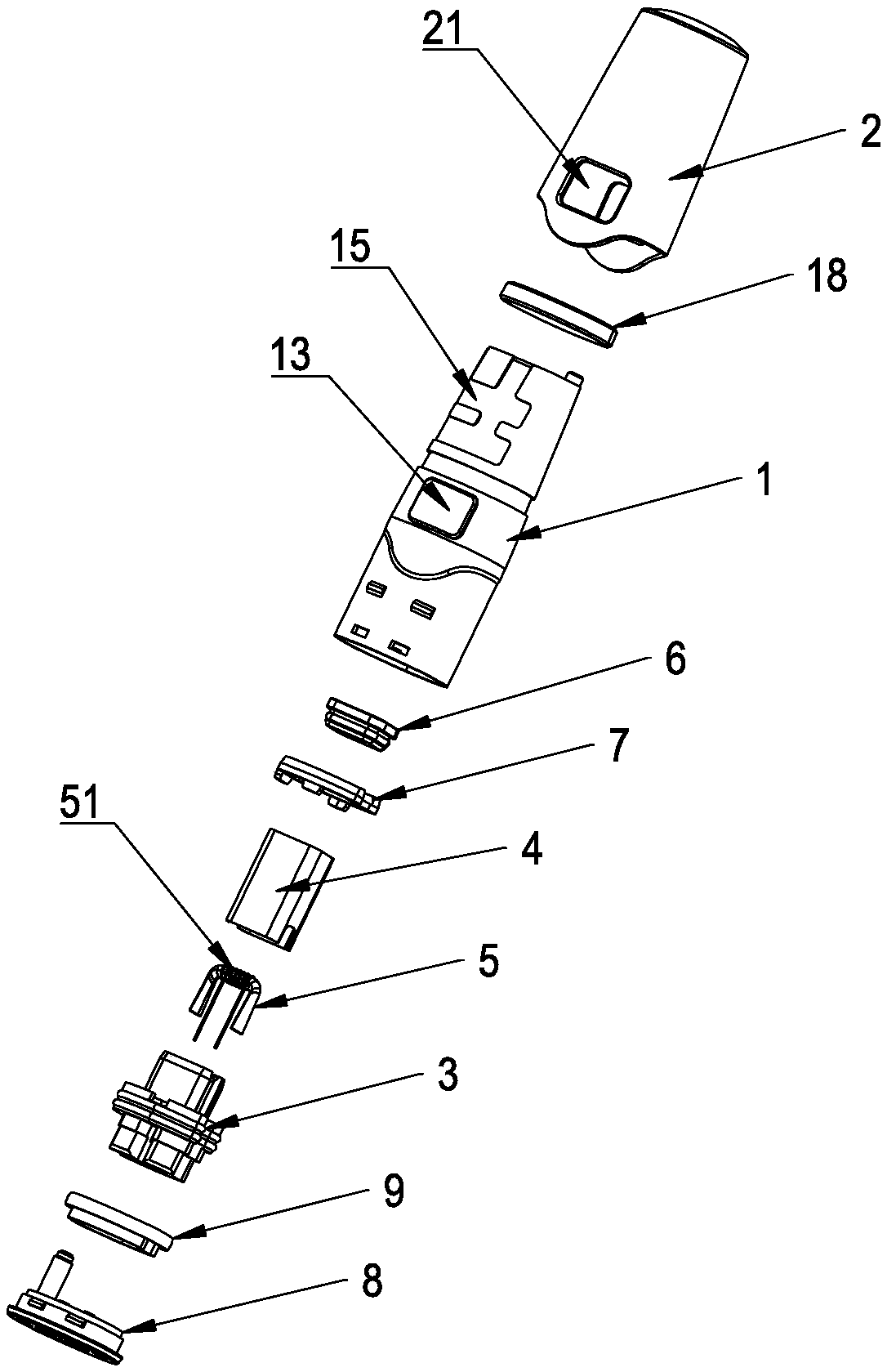

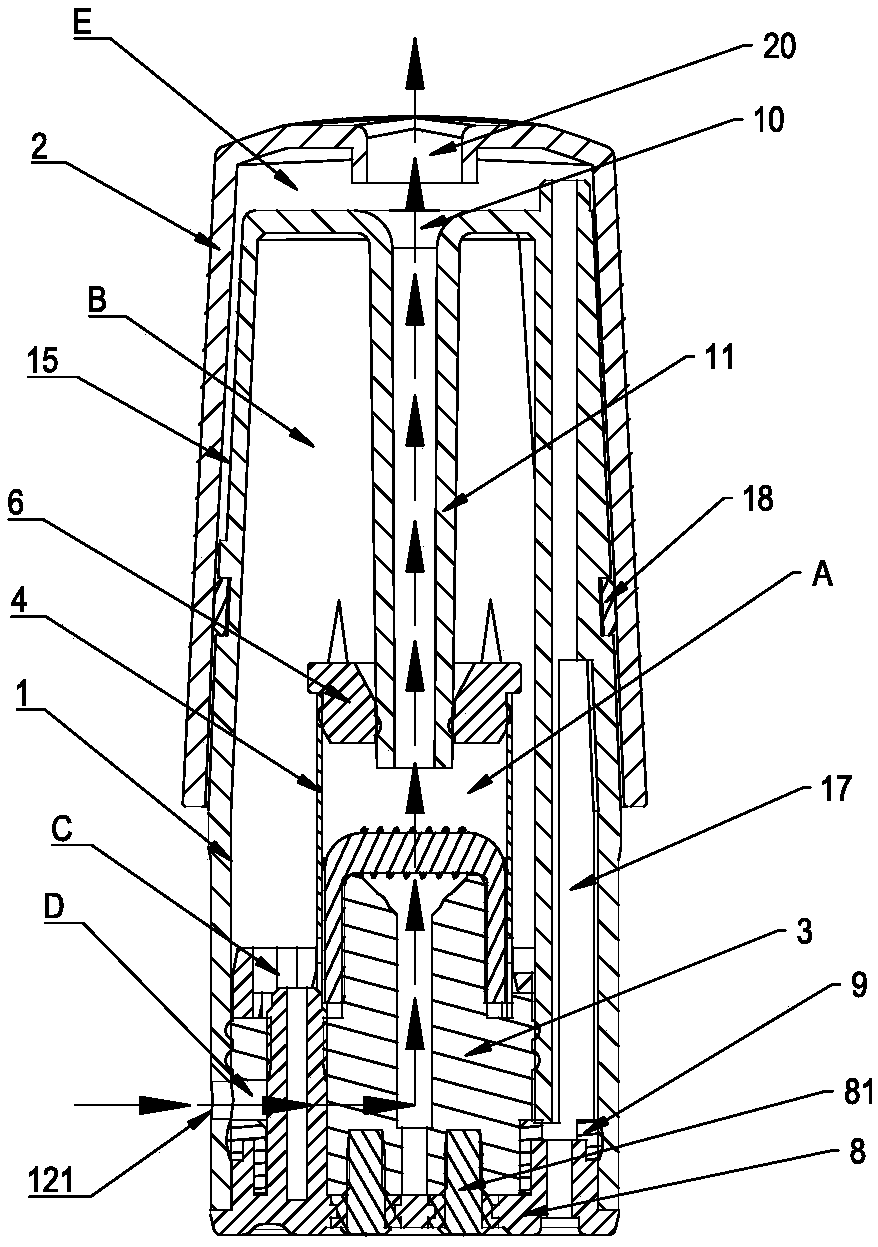

[0033] Such as Figure 1-Figure 4 As shown, the electronic cigarette atomizer of the present invention includes a casing 1 with the upper end sealed and the lower end open, and a suction nozzle 2 sleeved on the upper outer surface of the casing and having a suction hole 20 at the top. The center of the upper transverse wall of the casing 1 is located at the suction hole There is a smoke outlet 10 below 20, and the transverse wall extends downward along the smoke outlet 10 to provide a smoke outlet 11. The gap between the housing 1 and the suction nozzle 2 forms a smoke outlet E, and the inner wall of the lower end of the housing is sleeved with fog The atomization table 3 and the base 8, the bottom of the atomization table 3 is connected with the base 8, the base 8 is fastened and sealed to the lower end of the housing 1, the upper middle of the atomization table 3 is provided with an upper boss 31, and the middle of the upper boss 31 faces There is an air inlet 310 through th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap