Water chestnut granulator

A granulator and water chestnut technology, applied in grain processing, etc., can solve problems such as low efficiency, high cost of fully automatic production lines, and high labor intensity, and achieve the effects of reducing labor intensity, improving granulation efficiency, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment proposes a water chestnut granulator with low cost and which can effectively improve the cutting efficiency.

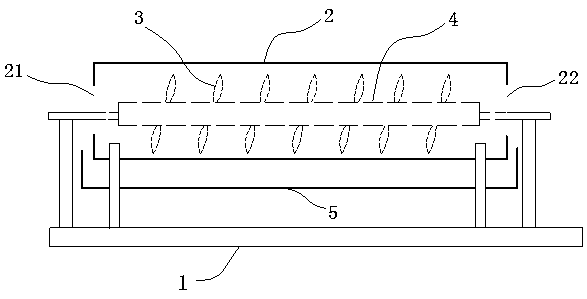

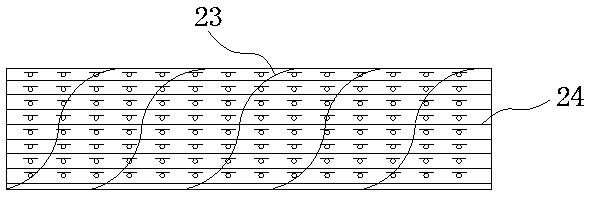

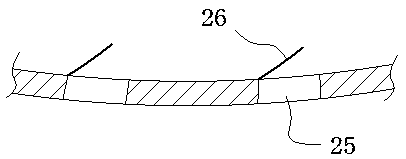

[0019] Such as figure 1 , 2 , 3, and 4, the water chestnut granulator of the present embodiment comprises a support 1 and a cylinder 2 that is rotatably installed on the support 1, and the cylinder 2 is connected with a first driving mechanism for driving the rotation of the cylinder 2; The end is provided with feed port 21 and discharge port 22 respectively, as figure 2 As shown, the inner wall of the drum 2 is provided with spiral ribs 23, and between the ribs 23 is provided with ribs 24 axially distributed along the drum 2, and the height of the ribs 23 is higher than the height of the ribs 24; The cylinder wall of 2 is evenly distributed with through holes 25, and the cylinder wall of the drum 2 is provided with a cutting plate 26 protruding toward the central axis of the drum 2 on the side of the through hole 25, and the end of the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com