A kind of preparation method of chloroprene rubber asphalt waterproof coating

A kind of asphalt waterproof coating and neoprene technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult feeding of cutters, high accumulation of asphalt blocks, and inability of asphalt blocks to be decomposed and unloaded, so as to improve the cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following embodiments of the present invention in conjunction with the accompanying drawings are described in detail, but the present invention may be implemented in a variety of different ways defined and covered by the claims.

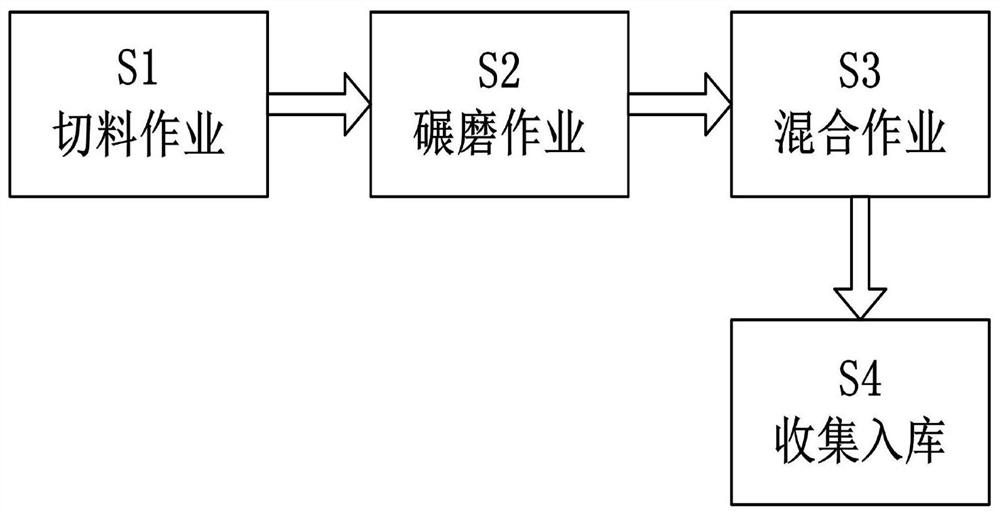

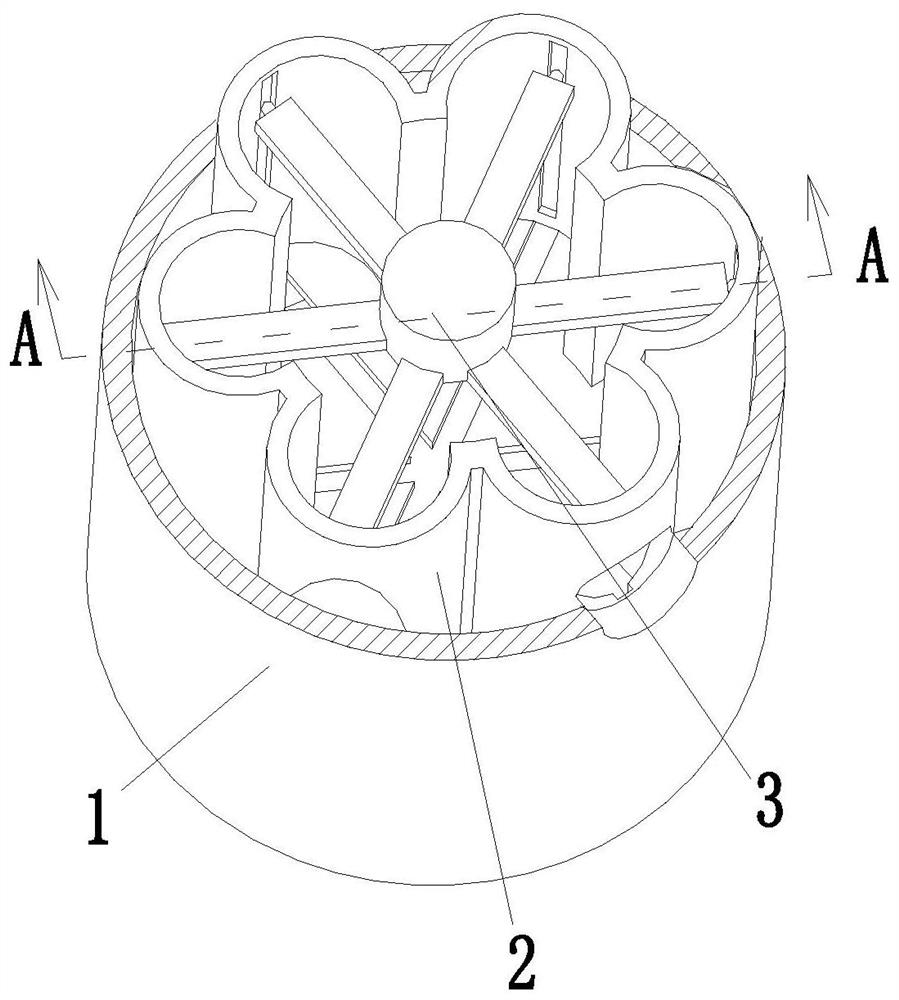

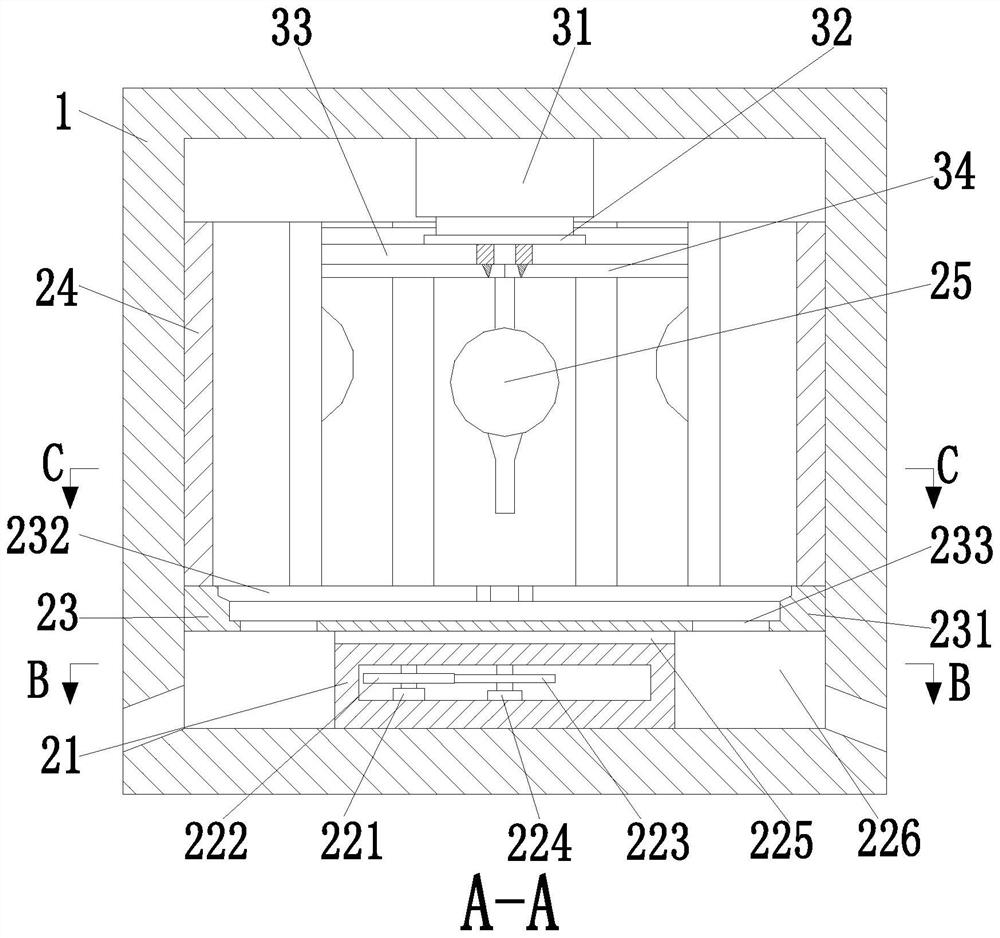

[0031] as Figures 1 through 6 A neoprene rubber asphalt waterproof coating preparation method shown, which uses an asphalt cutting equipment, asphalt cutting equipment comprising a cutting cylinder 1, a uniform feeding device 2 and a cutting unloading device 3 using the asphalt cutting equipment for the production process of waterproof coating further comprises the following steps:

[0032] S1, cutting operation: through the asphalt cutting equipment to decompose the asphalt into small pieces of uniform size;

[0033] S2, milling operation: through manual or mechanical assistance to grind asphalt into fine powder;

[0034] S3, mixing operation: the asphalt powder and neoprene powder are mixed and stirred evenly;

[0035] S4, collection and stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com