Handle for manual manufacture

A handle and manual technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of damaged coating surface, easy damage of electroplating coating, low protection effect, etc. keep the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

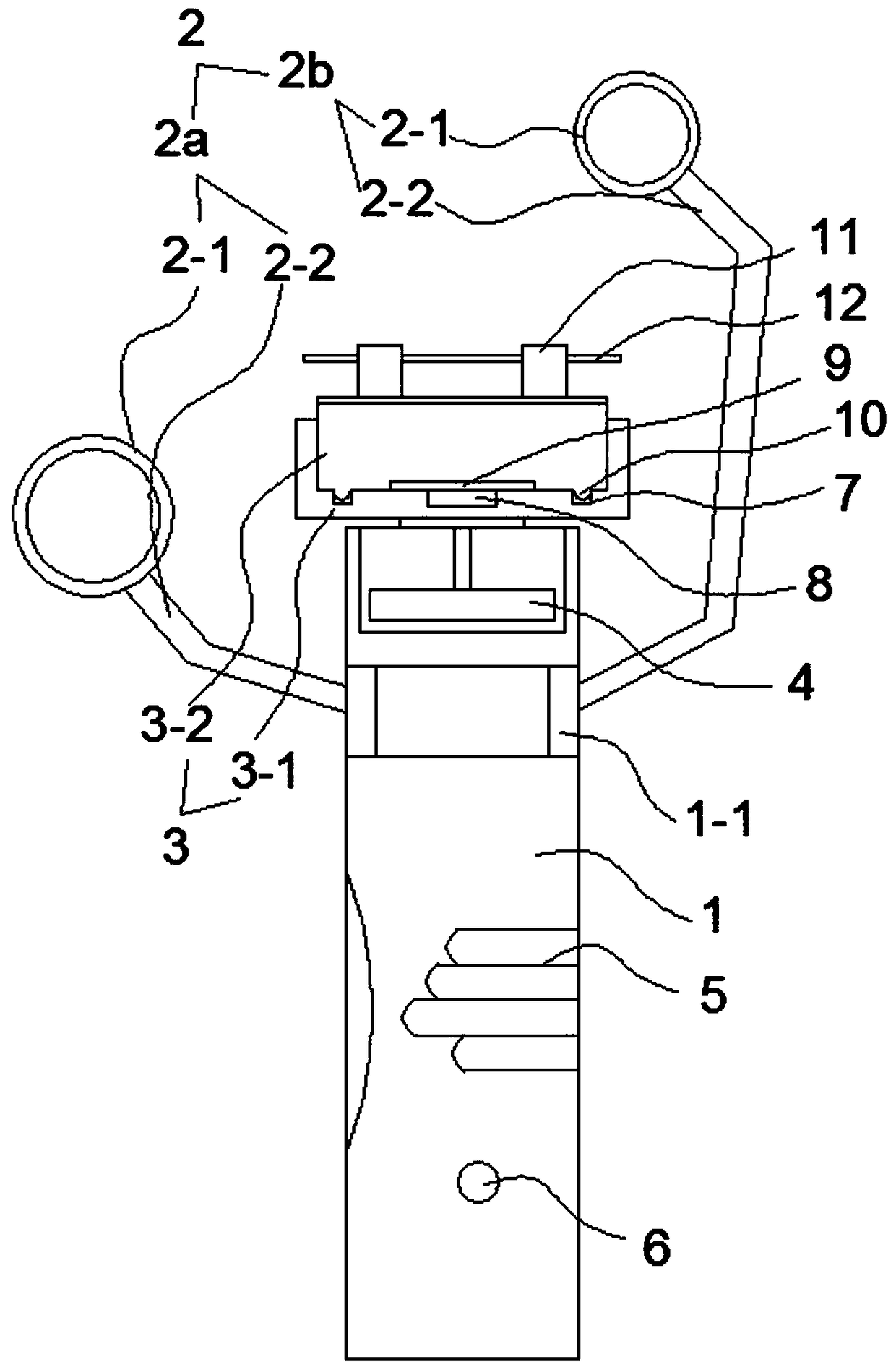

[0018] Such as figure 1 As shown, the embodiment of the present invention includes a handle part 1 for people to hold. The upper part of the handle part 1 is provided with at least one support ring 2 for providing support for extra fingers when the human hand holds it. The handle part 1 The upper end is provided with a connection platform 3 for connecting objects that need to be painted by hand. The connection platform 3 is connected to the handle part 1 through the rotation motor 4, and the rotation motor 4 drives the connection platform 3 to rotate, which provides an easier control for manual operators. The pen coating angle does not require the manual operator to twist the wrist to adjust the pen coating angle, which better controls the stability of the pen coating. The support ring 2 allows at least one finger to be lifted from the top of the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com