Green automatic dismantling device and method for waste tires

A green technology for waste tires, which is applied in the field of green automatic dismantling devices for waste tires, can solve the problems of time-consuming and laborious tire dismantling, and achieve the effects of efficient, reliable dismantling, and convenient classification and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

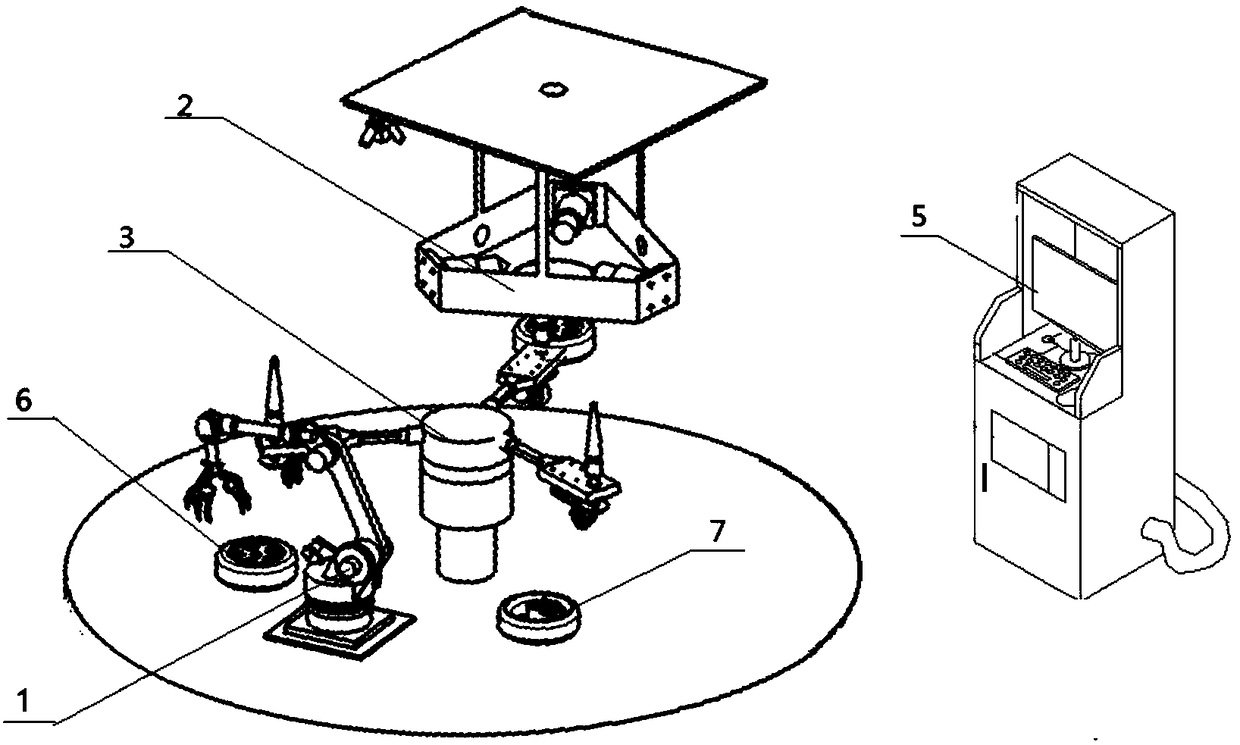

[0030] A green automatic dismantling device for waste tires, comprising a loading and unloading device 1, an extrusion device 2, a fixed feeding device 3 and a vision control device 5;

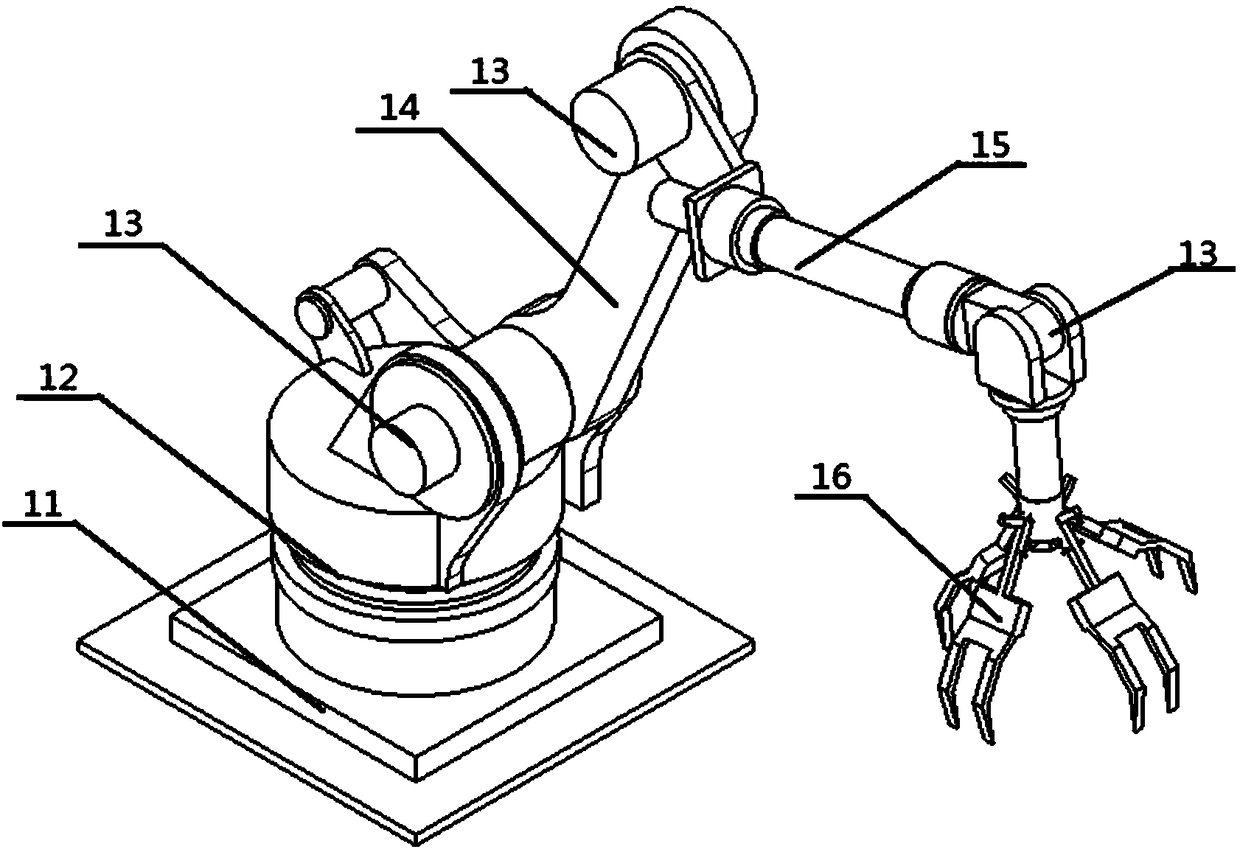

[0031] The loading and unloading device includes a base 11, a 360° rotating mechanism 12, a mechanical arm and a grip 16. One end of the 360° rotating mechanism 12 is fixed on the base 11, and the other end is connected to the mechanical arm. The mechanical arm is provided with a gripping 16 through a joint 13; the base 11 The mechanical arm is reliably supported, and there is a 360-degree rotating mechanism 12, which is convenient for the mechanical arm to grab objects without dead ends. The mechanical arm is made up of mechanical lower arm 14 and mechanical upper arm 15. The lower end of the mechanical lower arm 14 is installed on the base 11, and the top is connected to one end of the mechanical upper arm 15, and the mechanical upper arm 15 other end links to each other with the gripper 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com