Flat tail rope dismantling machine

A flat tail and rope pressing technology is applied in the field of flat tail rope dismantling machines, which can solve the problems of high labor intensity and low efficiency, and achieve the effects of less labor consumption, efficient dismantling and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

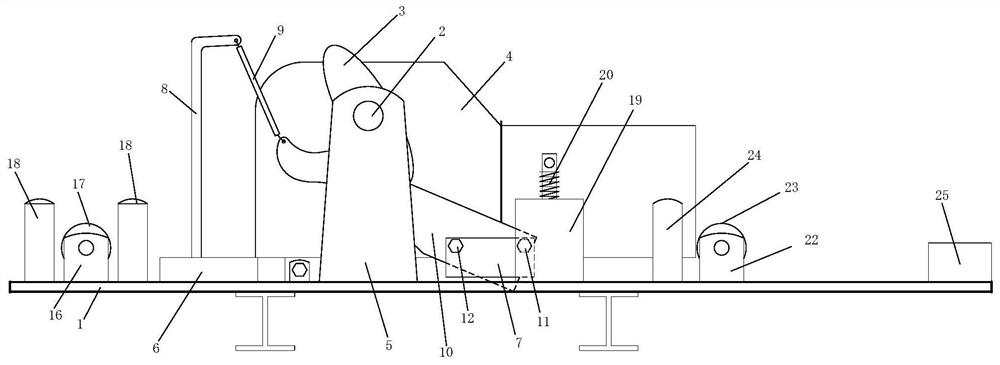

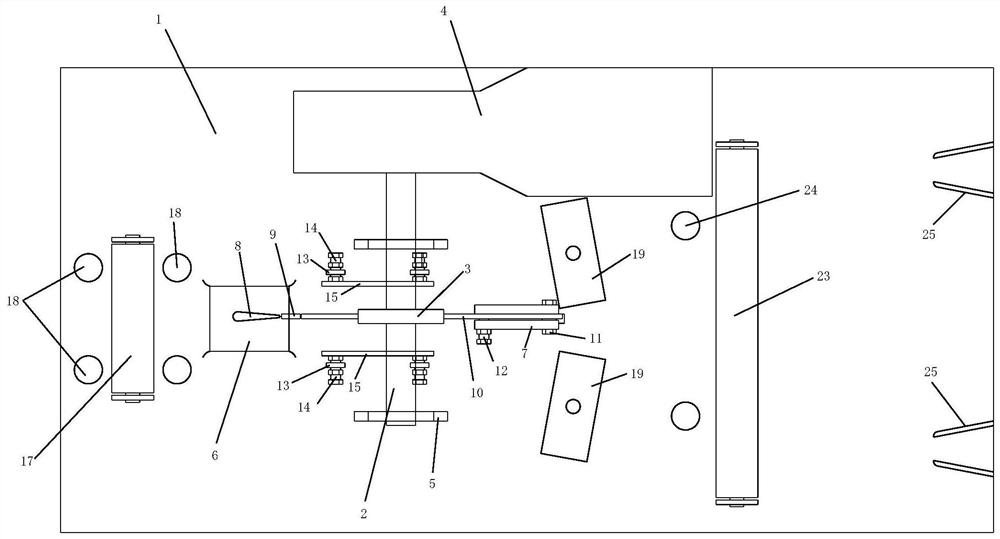

[0053]The working principle of the dismantling machine is explained with a flat tail rope composed of 8 main core wires.

[0054] The flat tail rope composed of 8 main core wires is braided by horizontal braided wires.

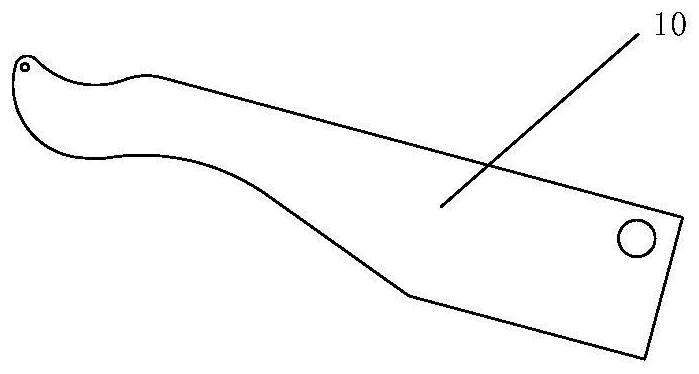

[0055] When splitting, the flat tail rope passes through the gap between the front rope pressing roller and the chassis, the gap between the spring rod seat and the chassis, and the fine-tuning structure in turn. The middle of the flat tail rope is cut at the cutter and divided into two parts. , each part of the rope is composed of 4 main core wires and broken braided wires, each part of the rope first passes through the gap between the limit card seat and the chassis, then goes around the outside of the guide column, and then passes through the rear pressure rope There is a gap between the roller and the chassis, and finally at the rope separating plate, it is split into 1 main core wire at the end and the remaining 3 main core wires by the rope separating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com