Patents

Literature

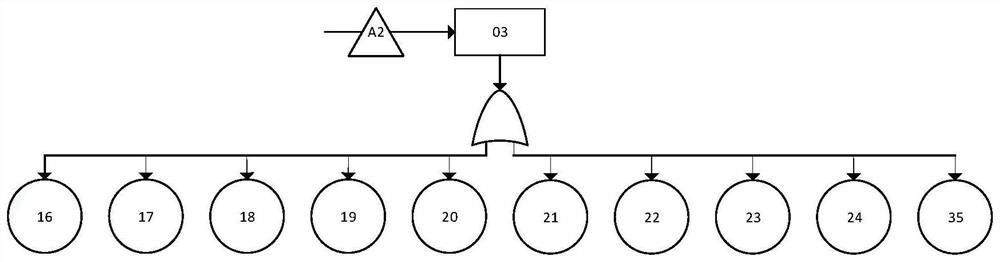

38results about How to "Efficient dismantling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

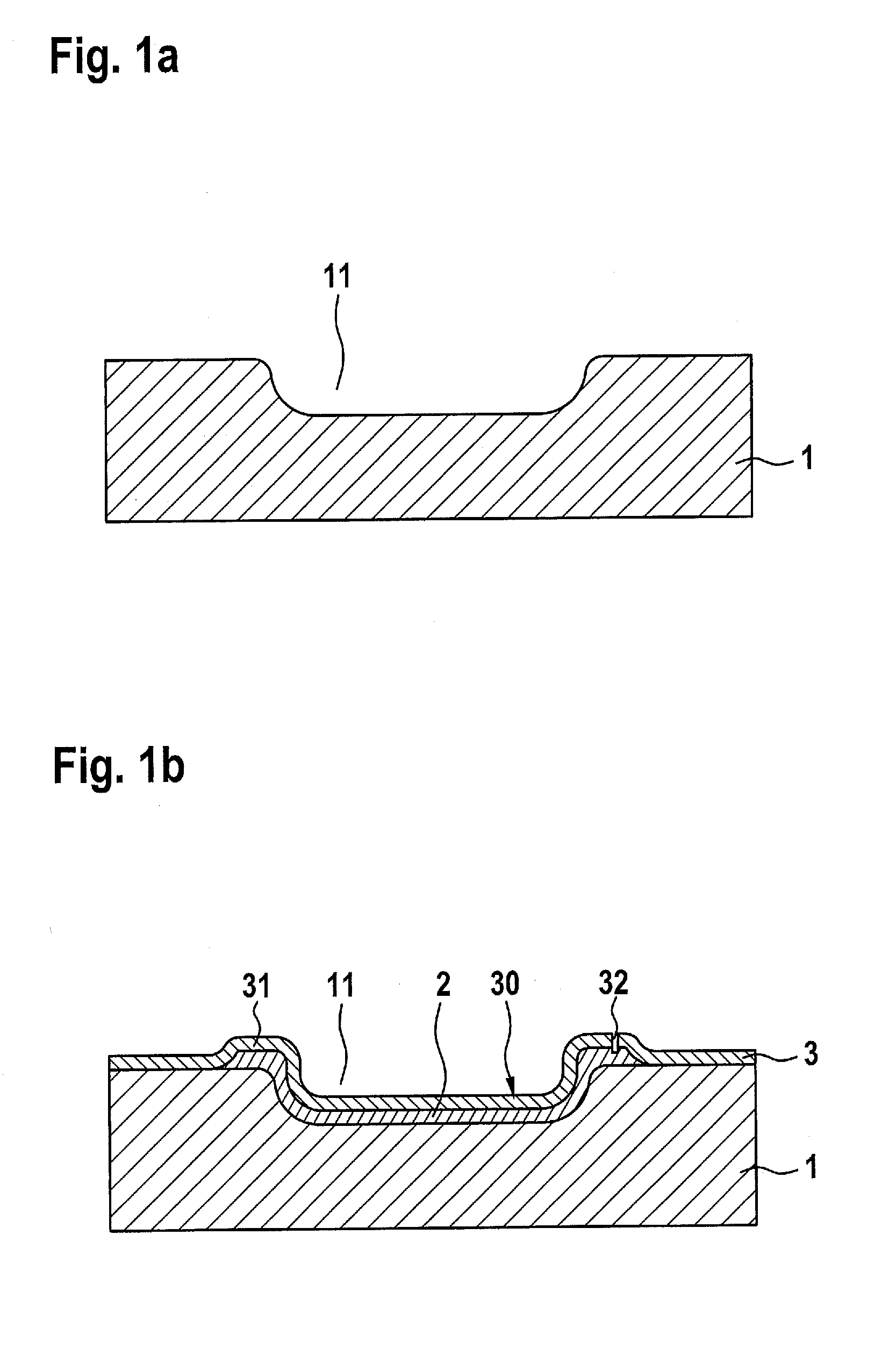

MEMS device having a microphone structure, and method for the production thereof

ActiveUS9403670B2Improve sealingReduce generationMicrophonesDecorative surface effectsCapacitanceEngineering

Owner:ROBERT BOSCH GMBH

MEMS device having a microphone structure, and method for the production thereof

ActiveUS20150014797A1Good acoustic sealReduce generationMicrophonesDecorative surface effectsEngineeringFree edge

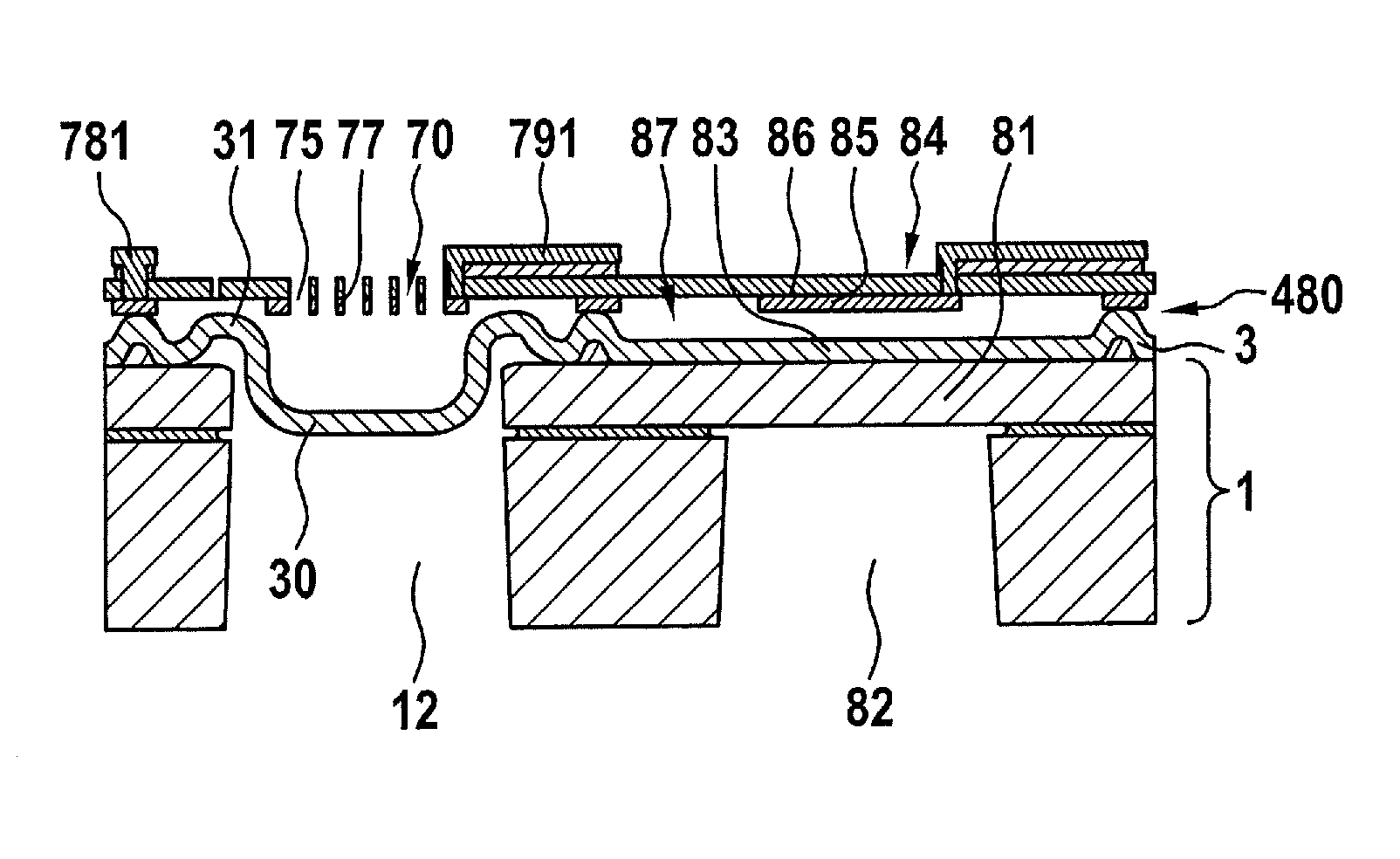

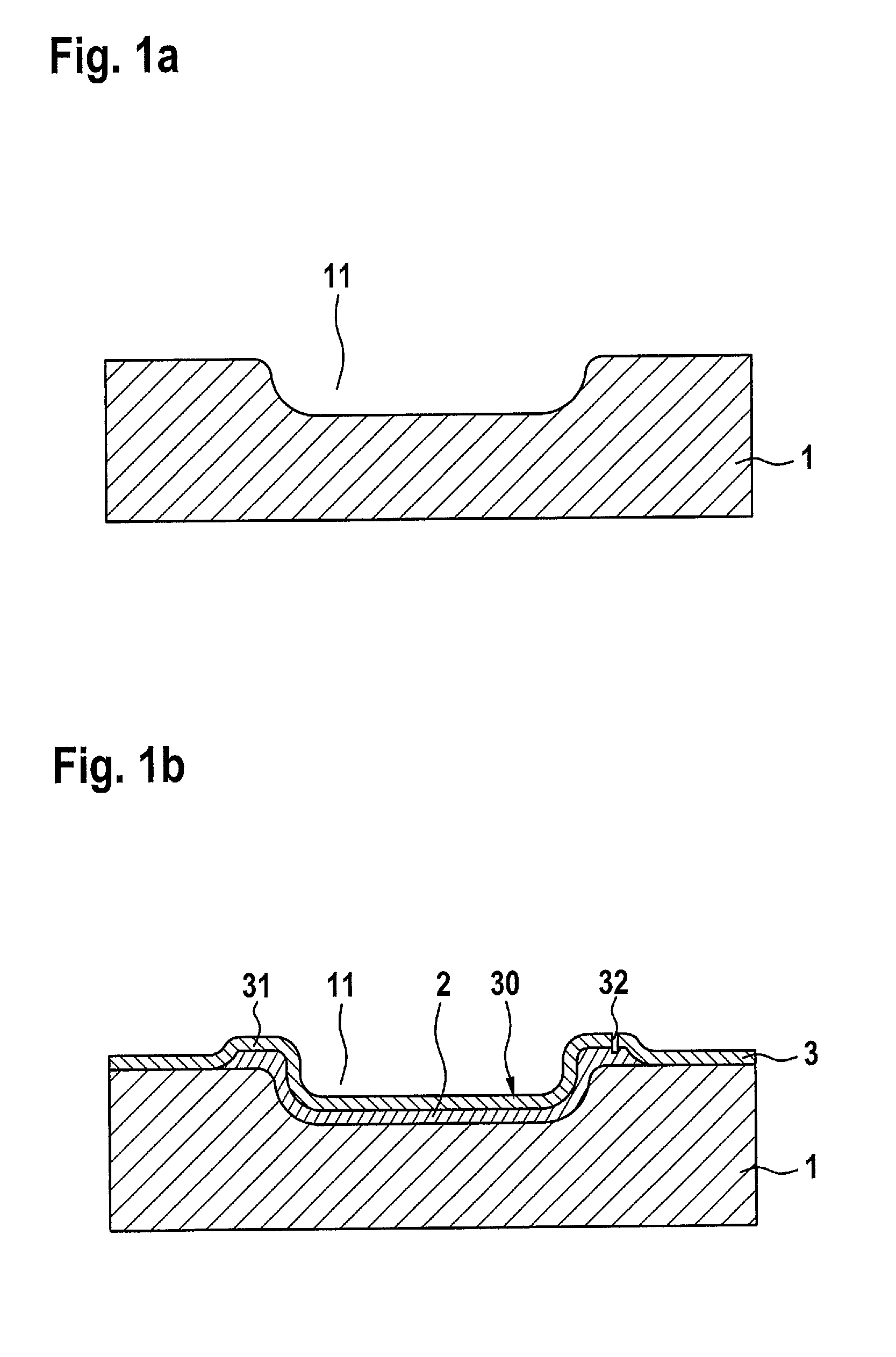

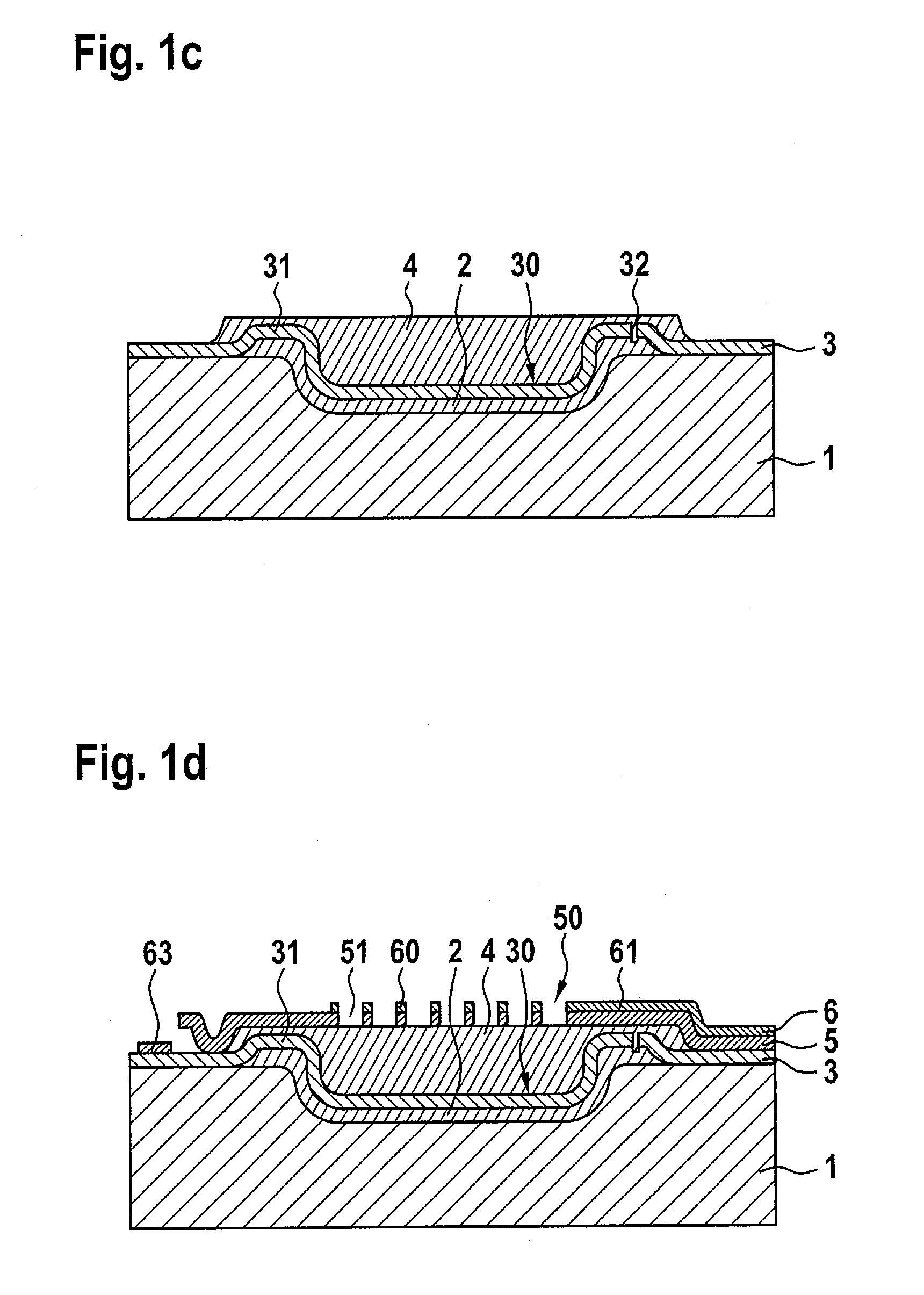

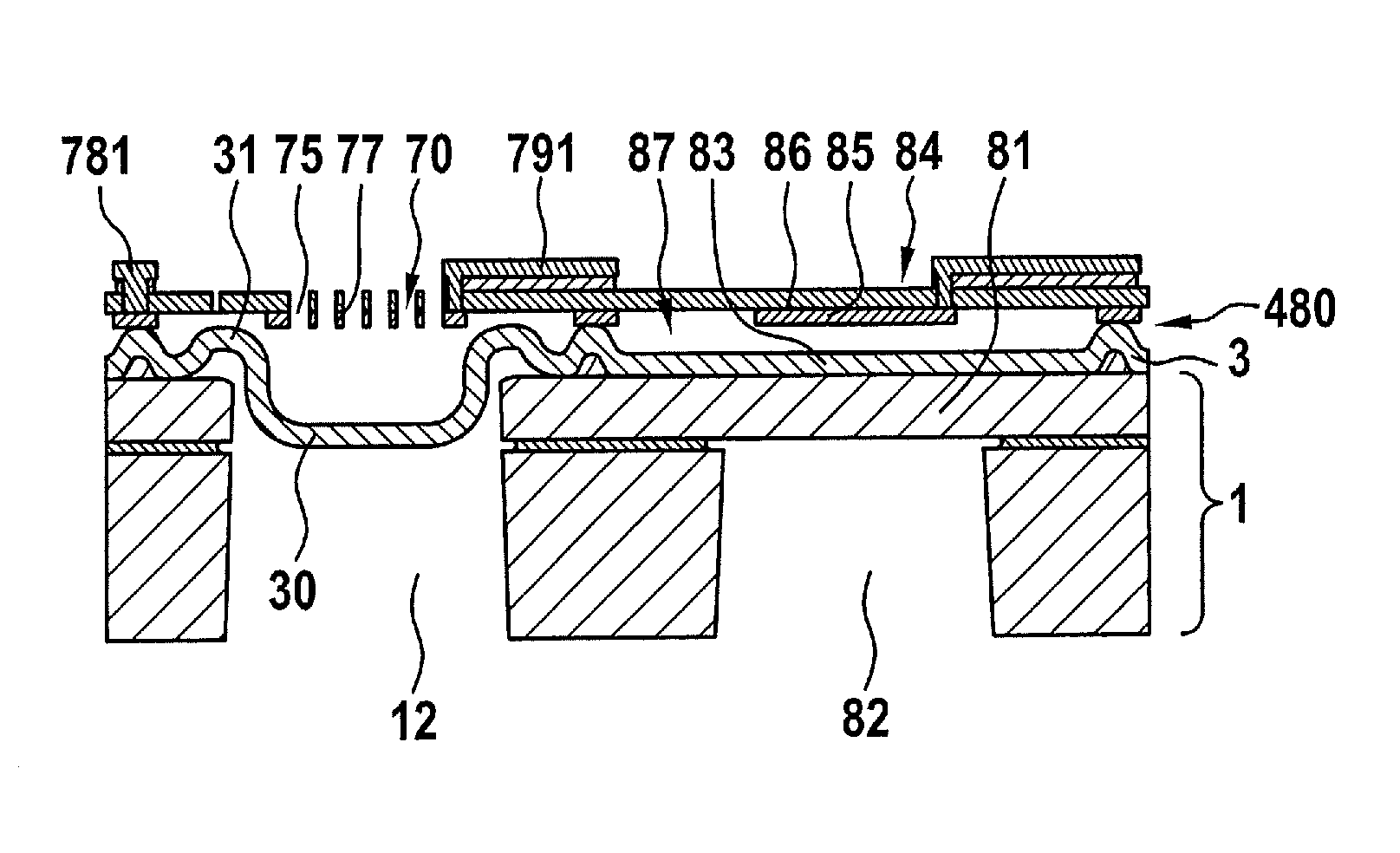

A microphone structure of an MEMS device has a layer construction including: a base substrate; a deflectable microphone diaphragm at least partly spanning a through-opening in the substrate; a deflectable electrode of a microphone condenser system; a stationary counter-element having ventilation openings situated in the layer construction over the microphone diaphragm and acting as a bearer for a stationary electrode of the microphone condenser system. The diaphragm is bonded into the layer construction on the substrate via a flexible beam. The otherwise free edge region of the diaphragm is curved in a pan shape, so that it extends both vertically and also in some regions laterally beyond the edge region of the through-opening, and the edge region of the through-opening forms a lower stop for the diaphragm movement.

Owner:ROBERT BOSCH GMBH

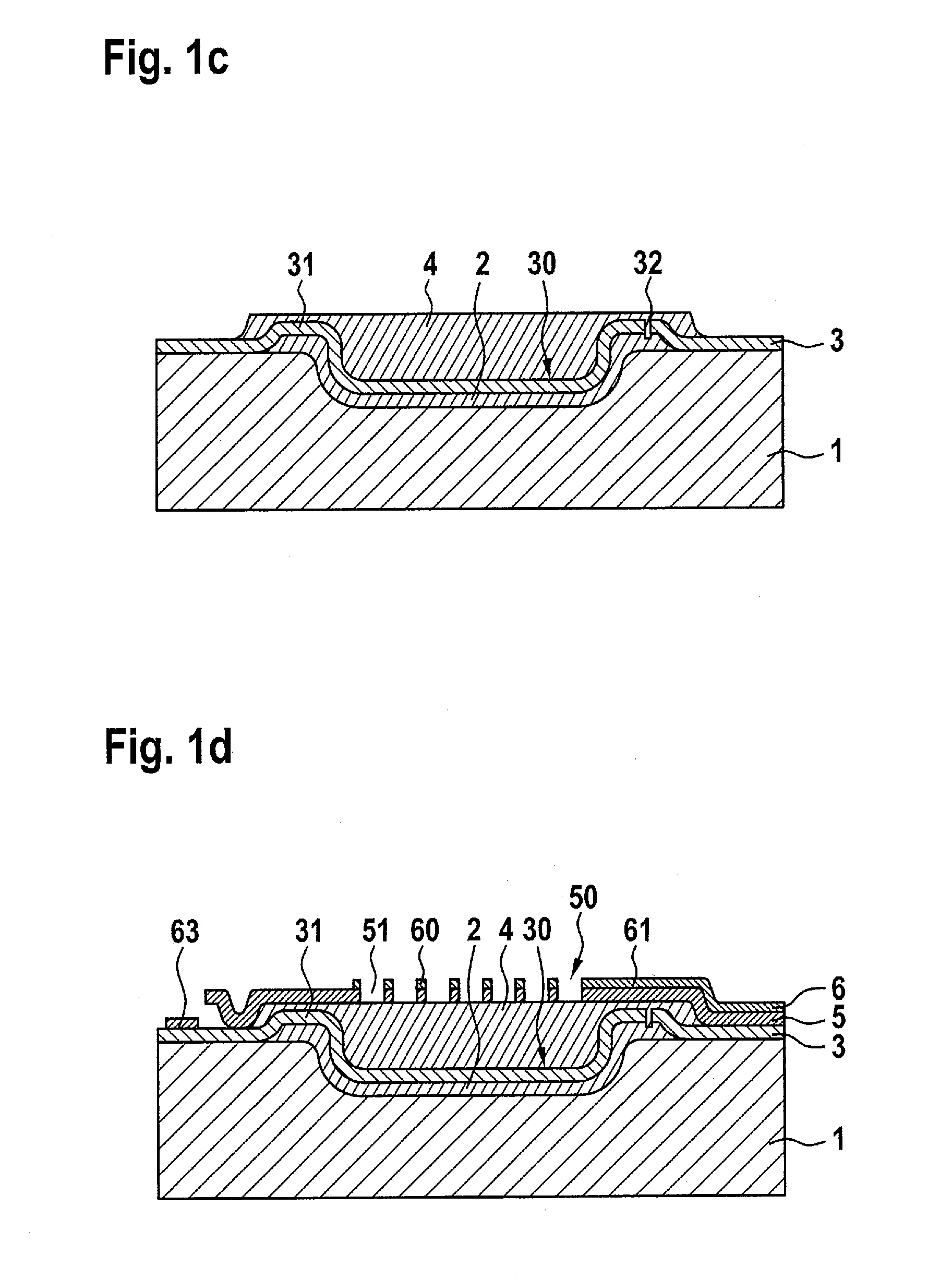

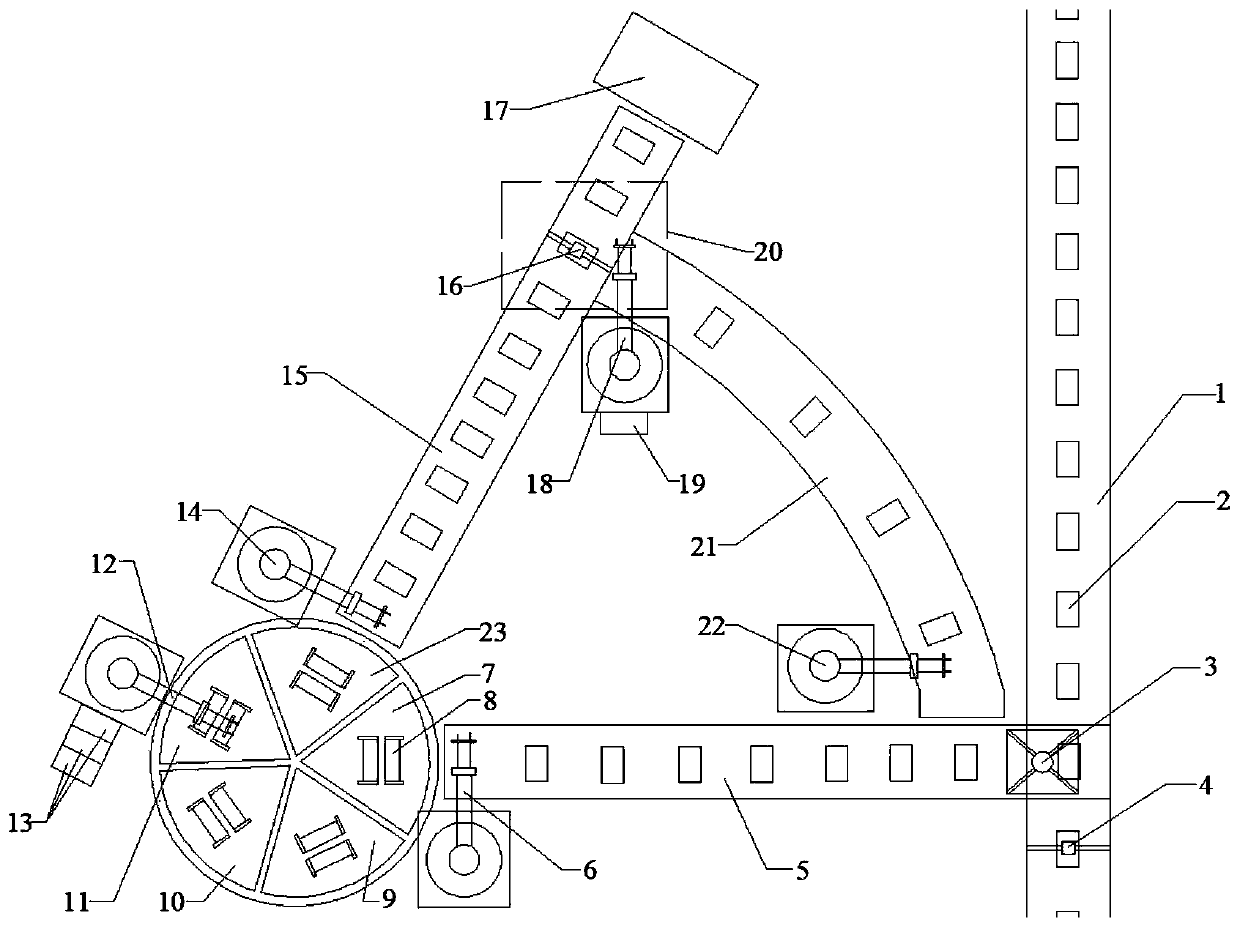

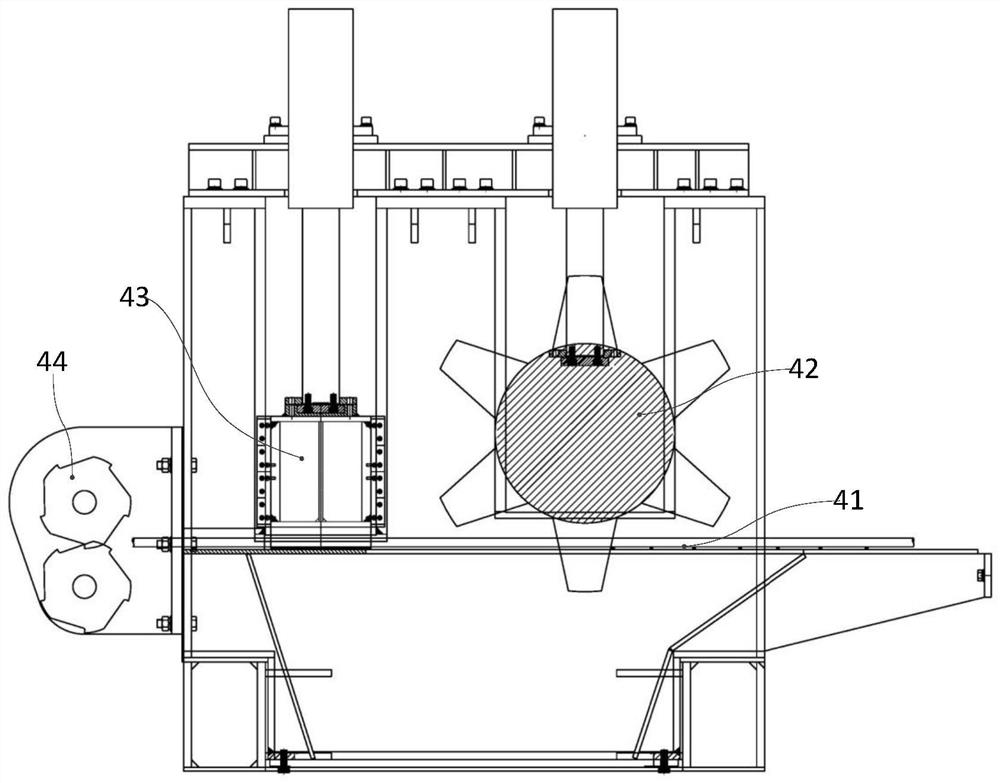

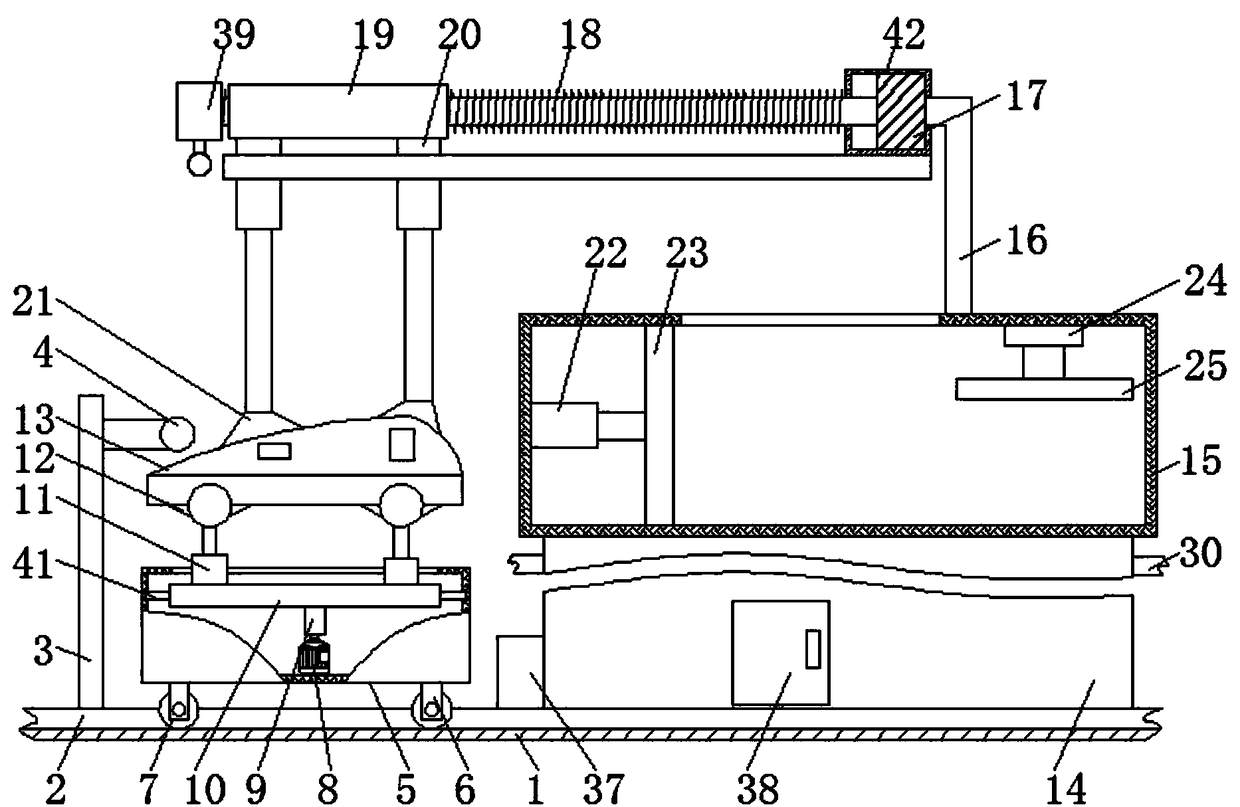

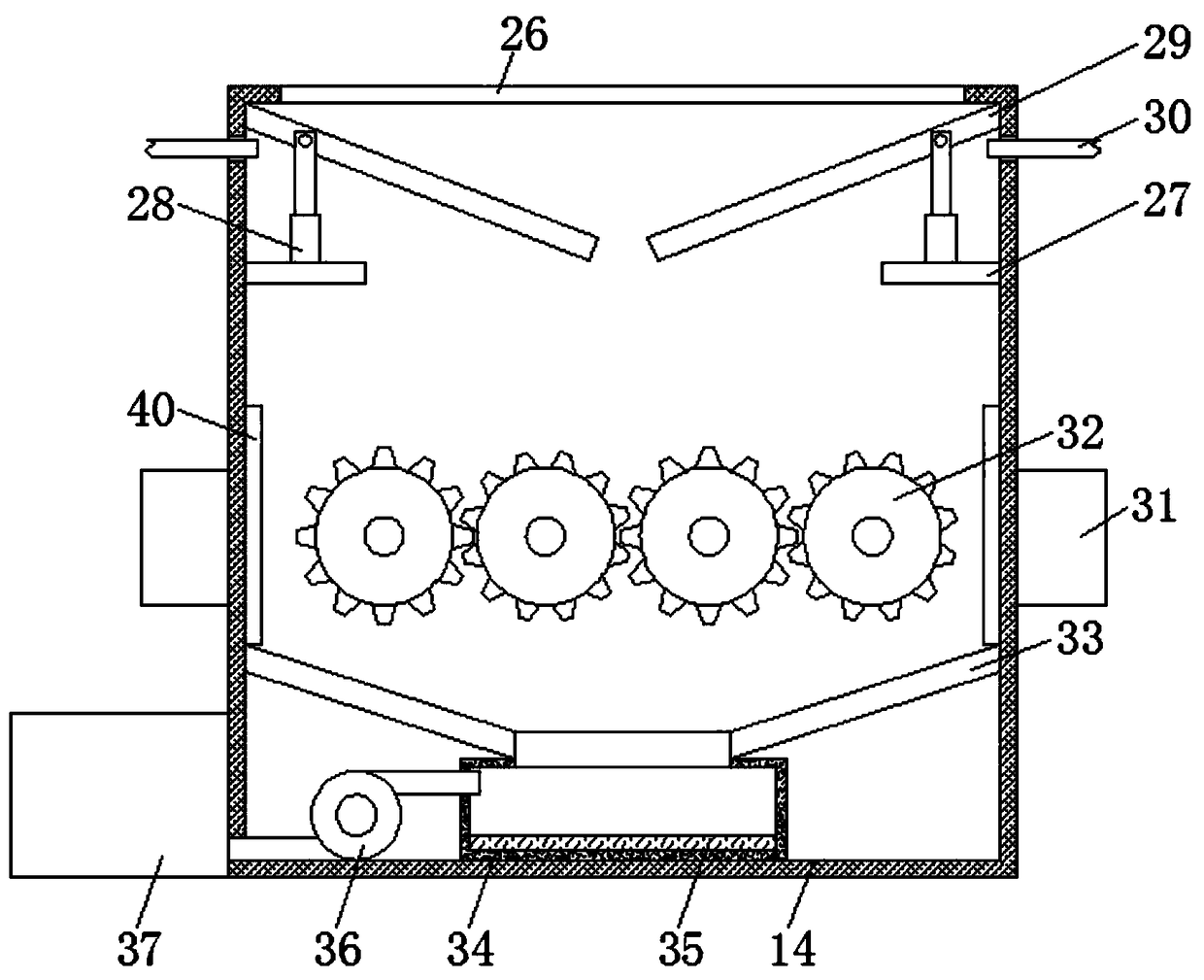

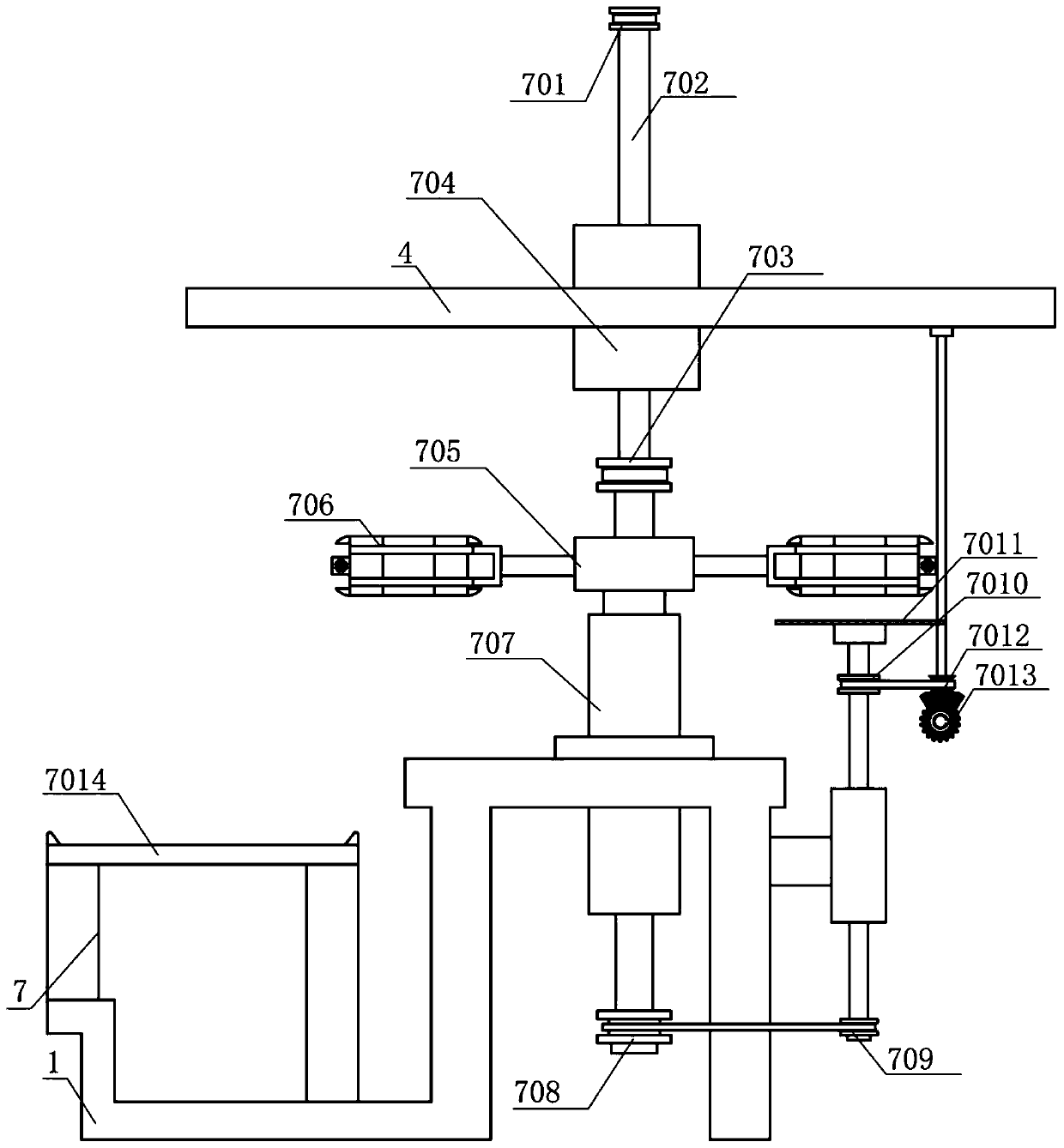

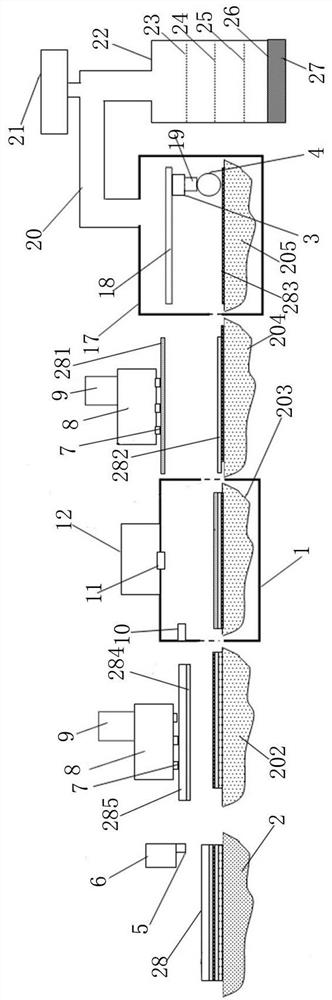

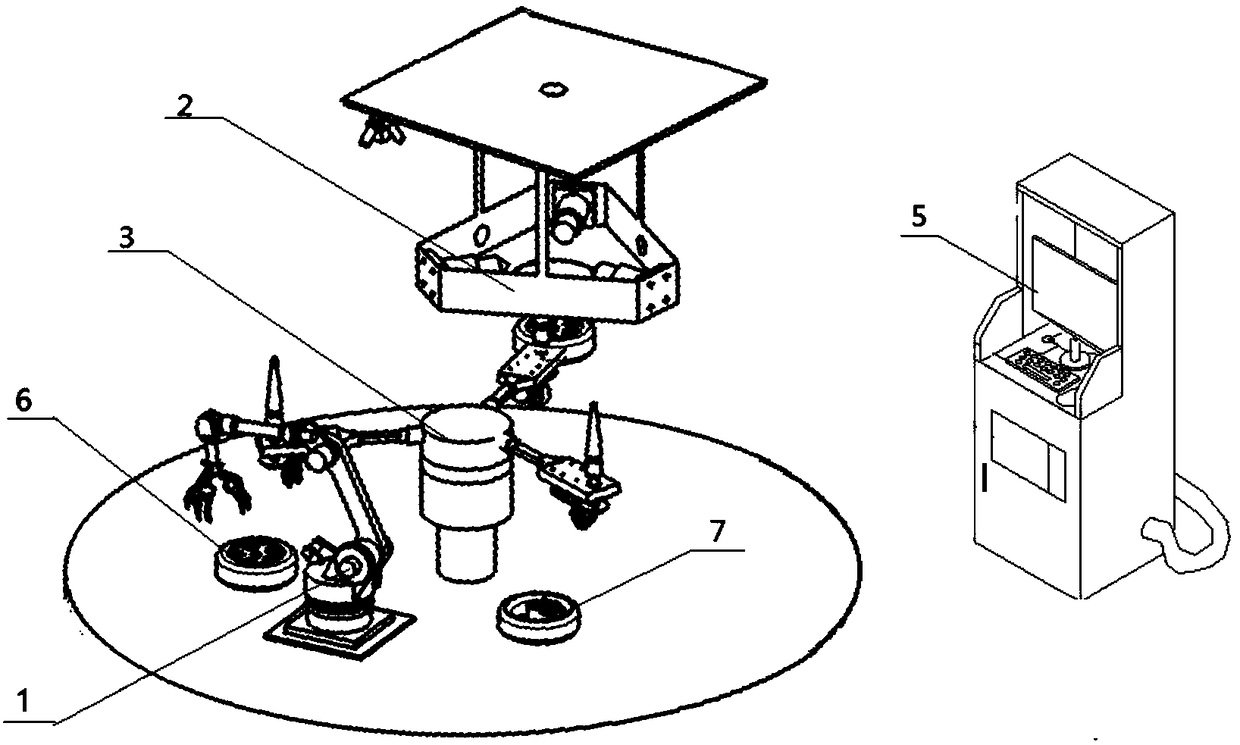

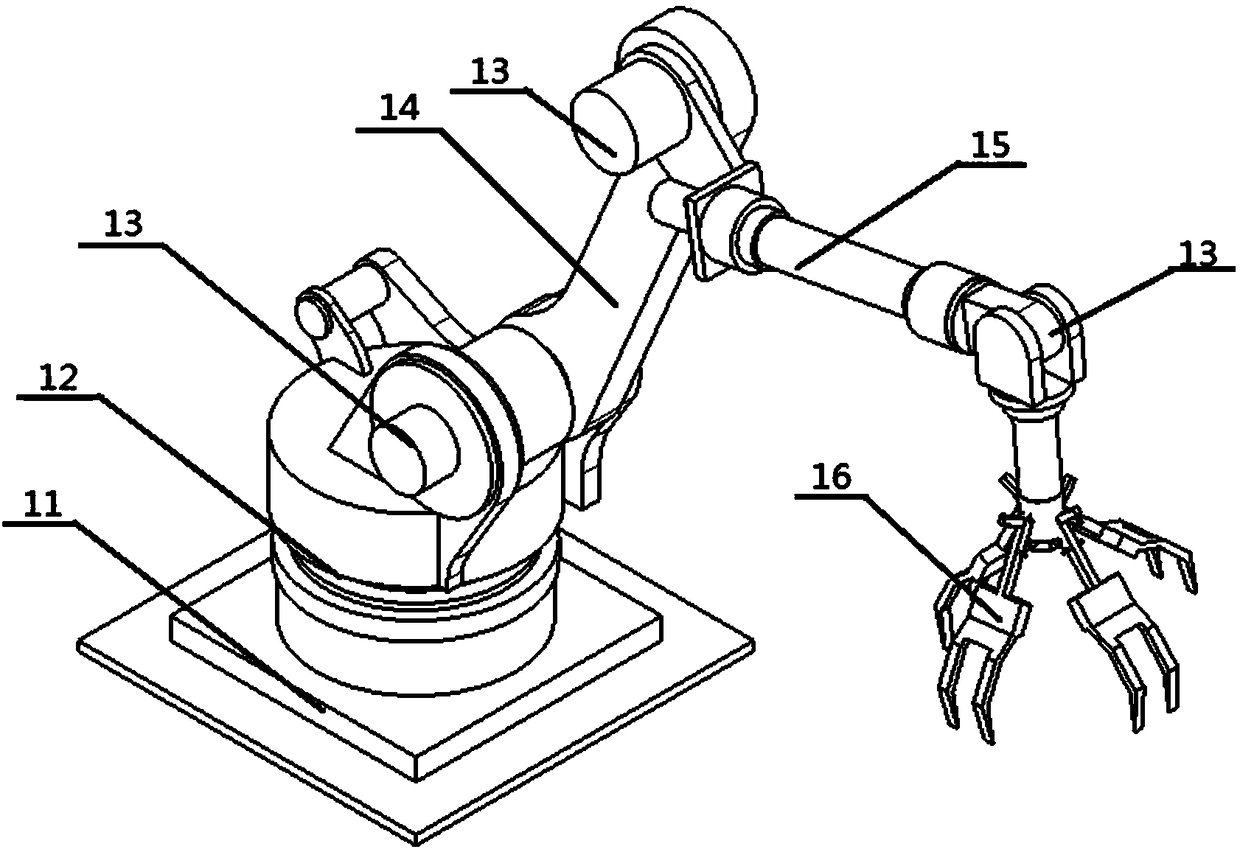

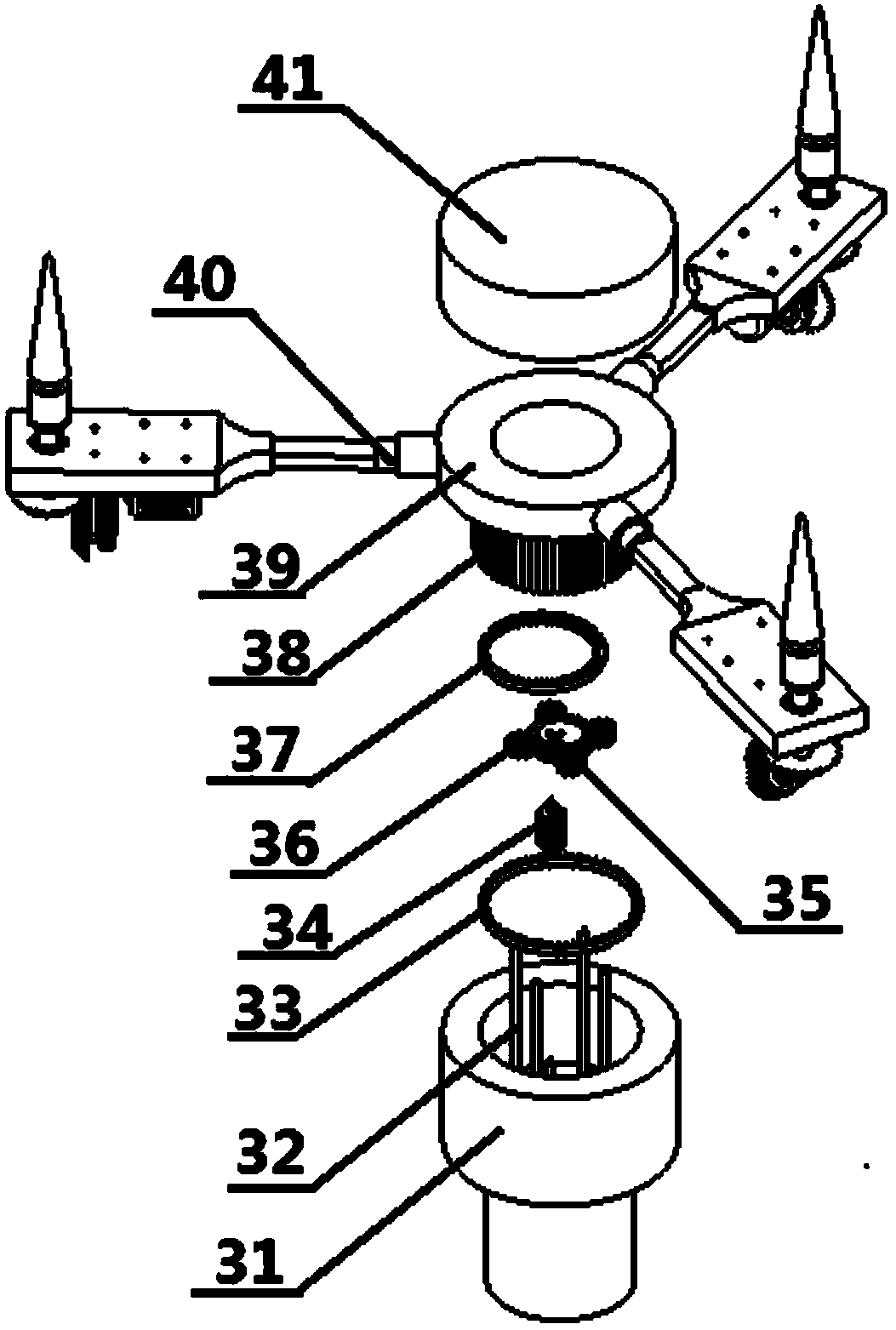

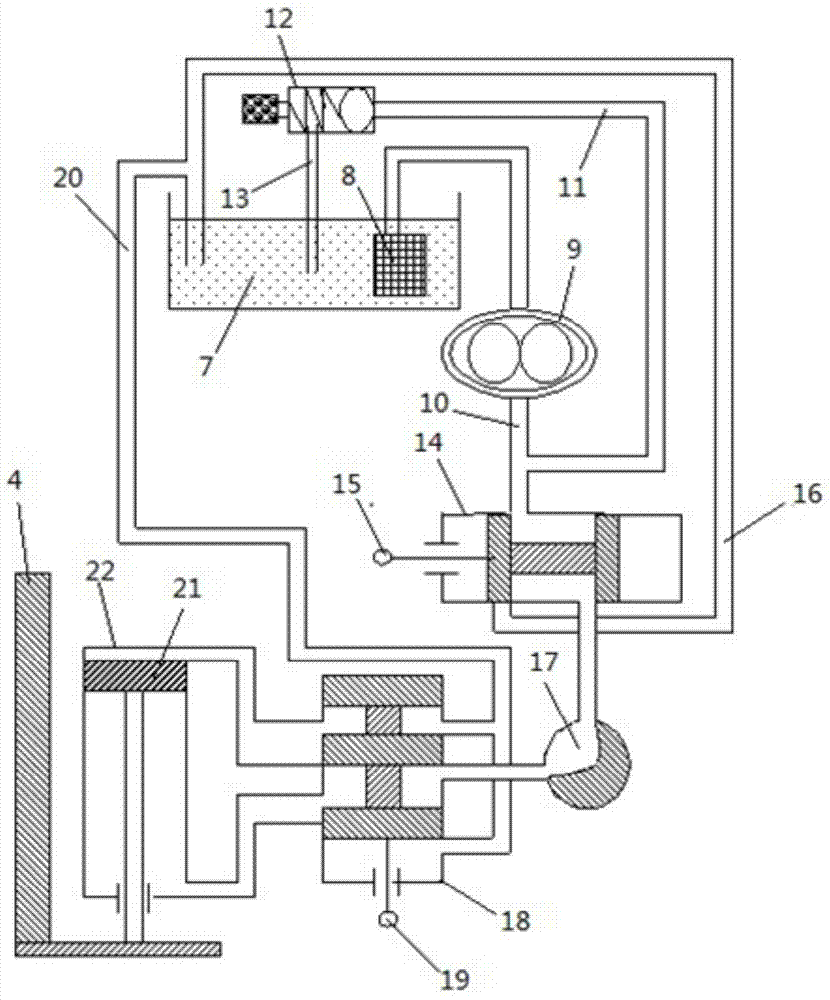

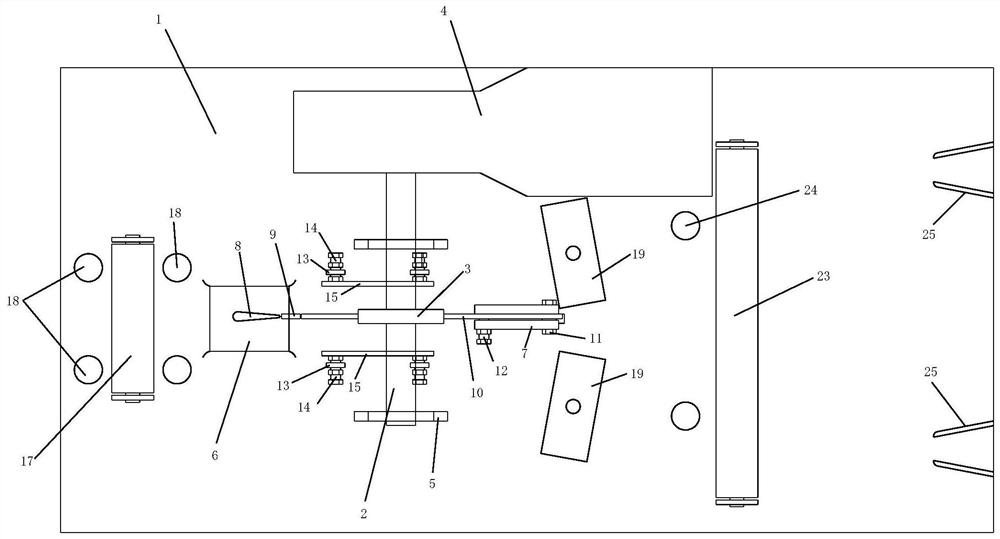

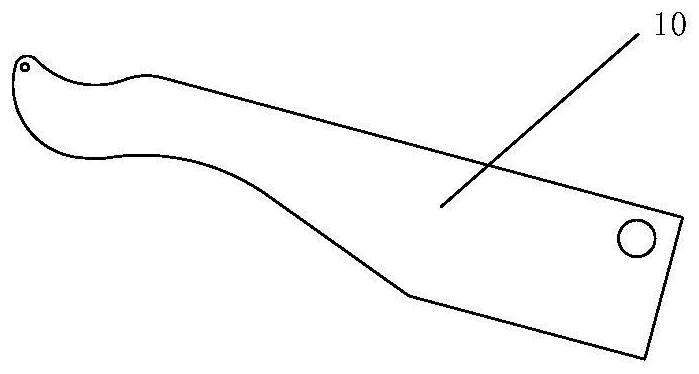

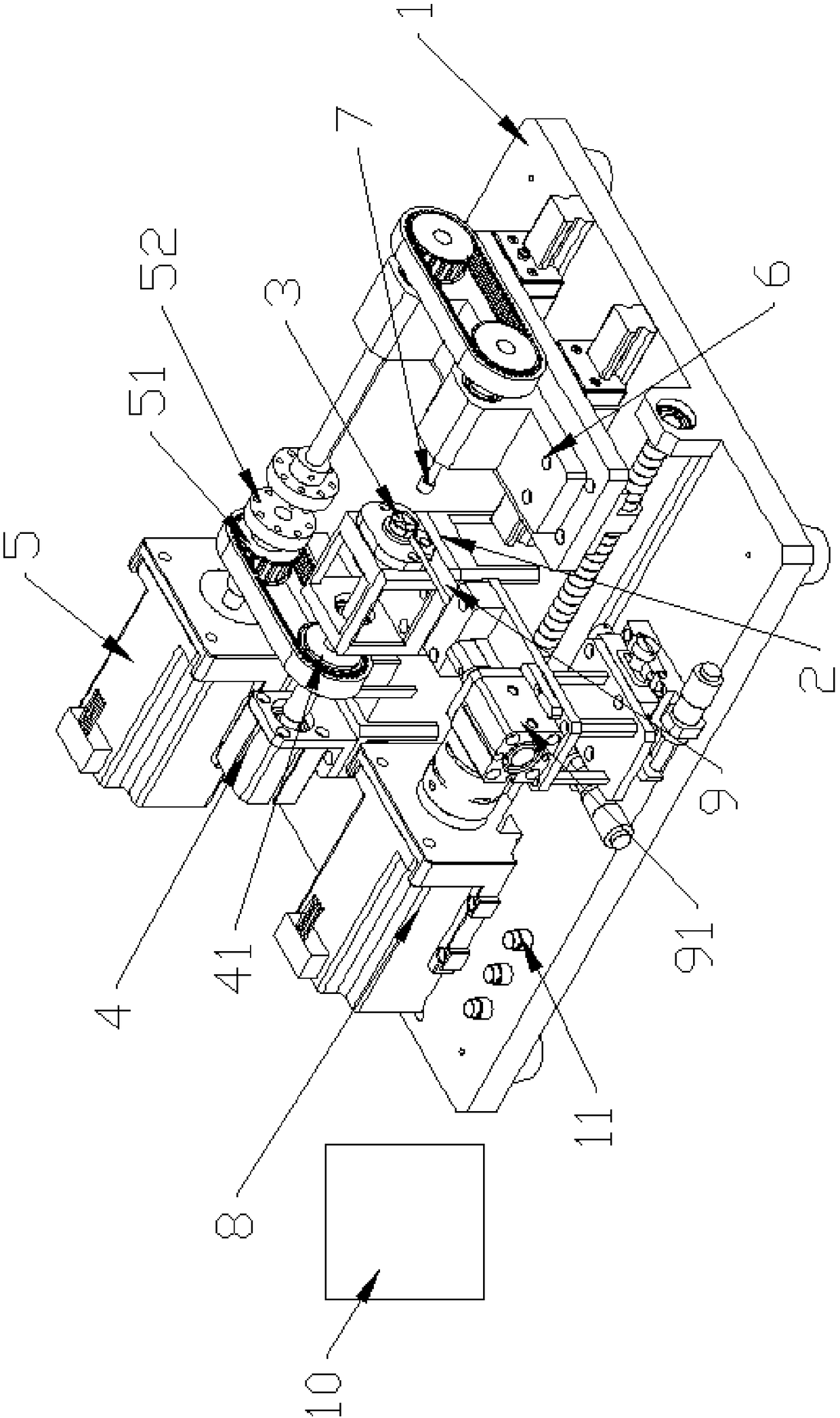

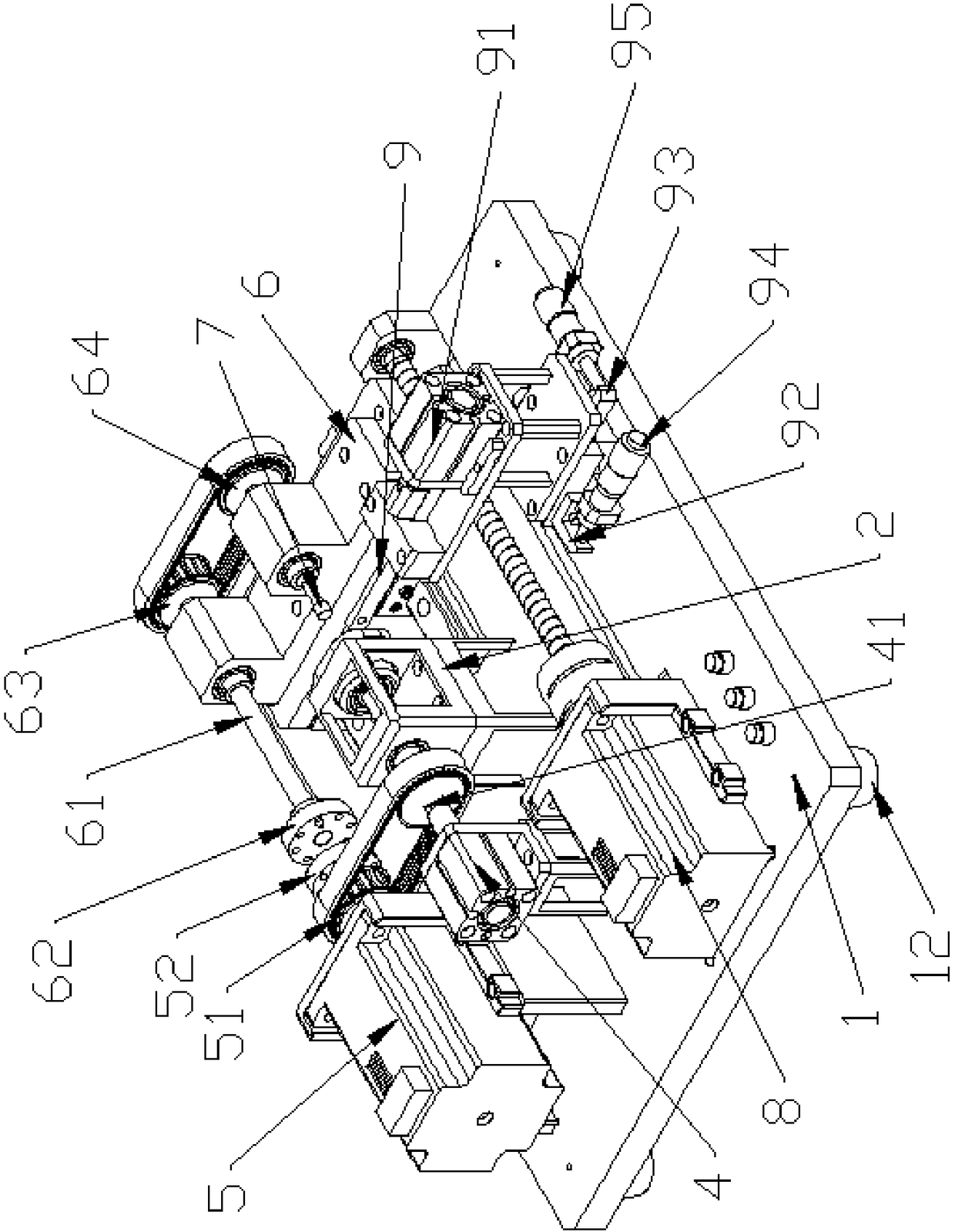

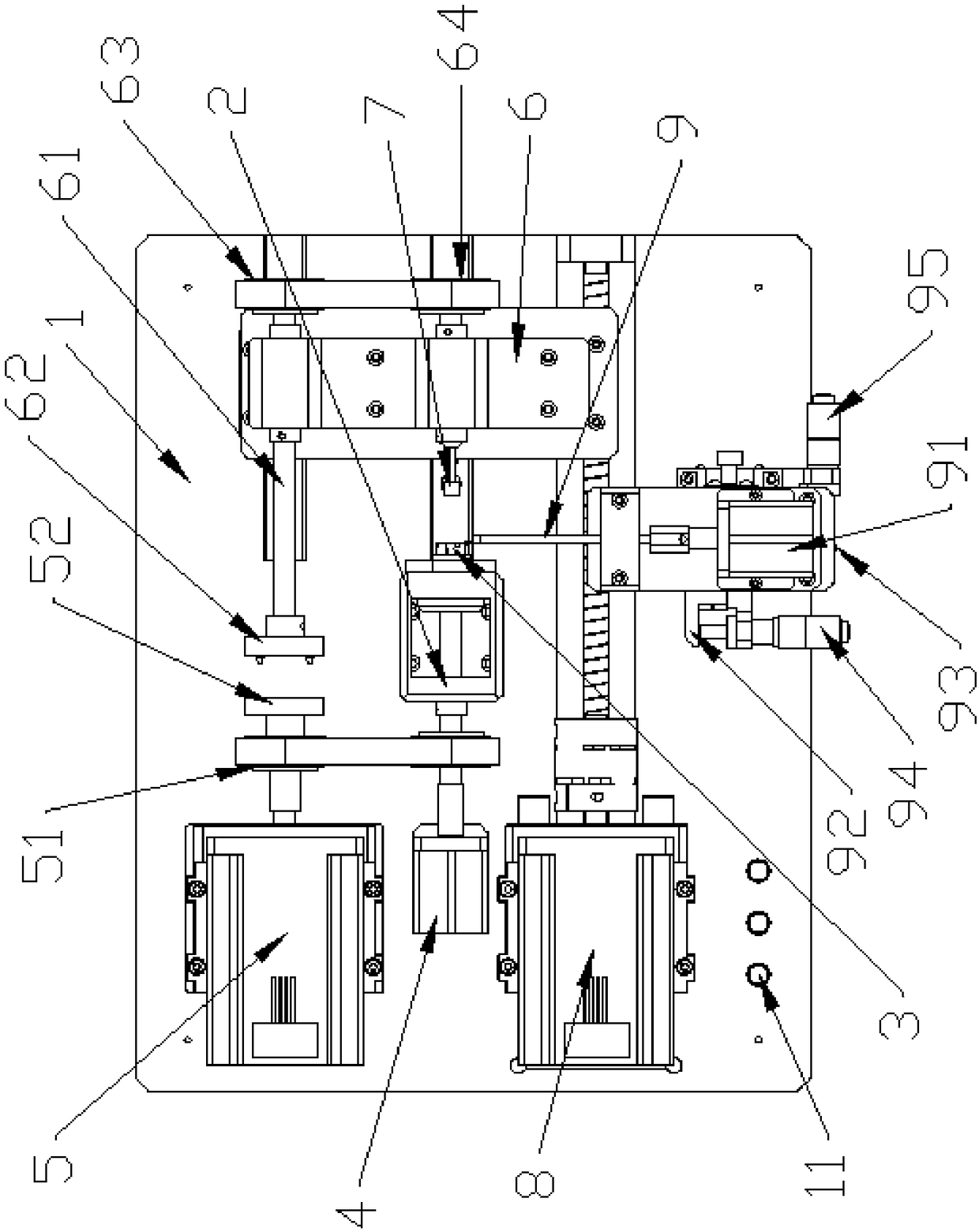

Automatic disassembly equipment appliable to flow process and used for waste mobile phones

InactiveCN110918619AReach environmentally friendly dismantlingEfficient dismantlingSolid waste disposalTransportation and packagingIndustrial roboticsMechanical engineering

The invention discloses automatic disassembly equipment appliable to a flow process and used for waste mobile phones, relates to the technical field of environment protection of waste mobile phones, and mainly aims at solving the problems of low disassembly efficiency, low recovery value and the like of a disassembly line for mobile phones. The disassembly equipment comprises a loading system, a rotary-disc flow disassembly mechanism and an unloading system, wherein the rotary-disc flow disassembly mechanism comprises a rotary-disc disassembly table, and five disassembly areas formed at the side of the rotary-disc disassembly table; the five disassembly areas are a loading area, a first disassembly area, a second disassembly area, a third disassembly area and an unloading area separately;the table surface of the rotary-disc disassembly table is correspondingly divided into five placement areas for the mobile phones; and an electric clamping mechanism is arranged in each placement areafor the mobile phones. The disassembly equipment carries out information obtaining and transferring, and execution for a disassembly process by virtue of an industrial camera, an industrial robot andthe like, and is high in automation degree.

Owner:QINGDAO UNIV OF SCI & TECH

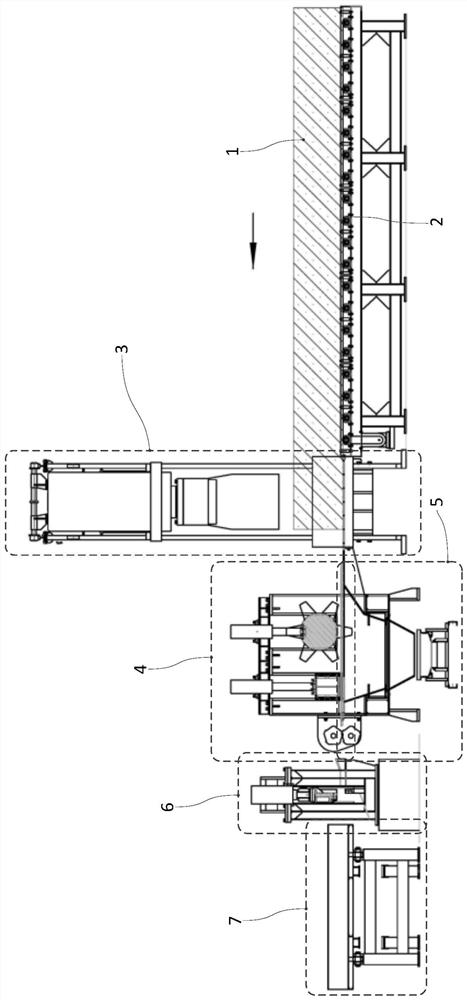

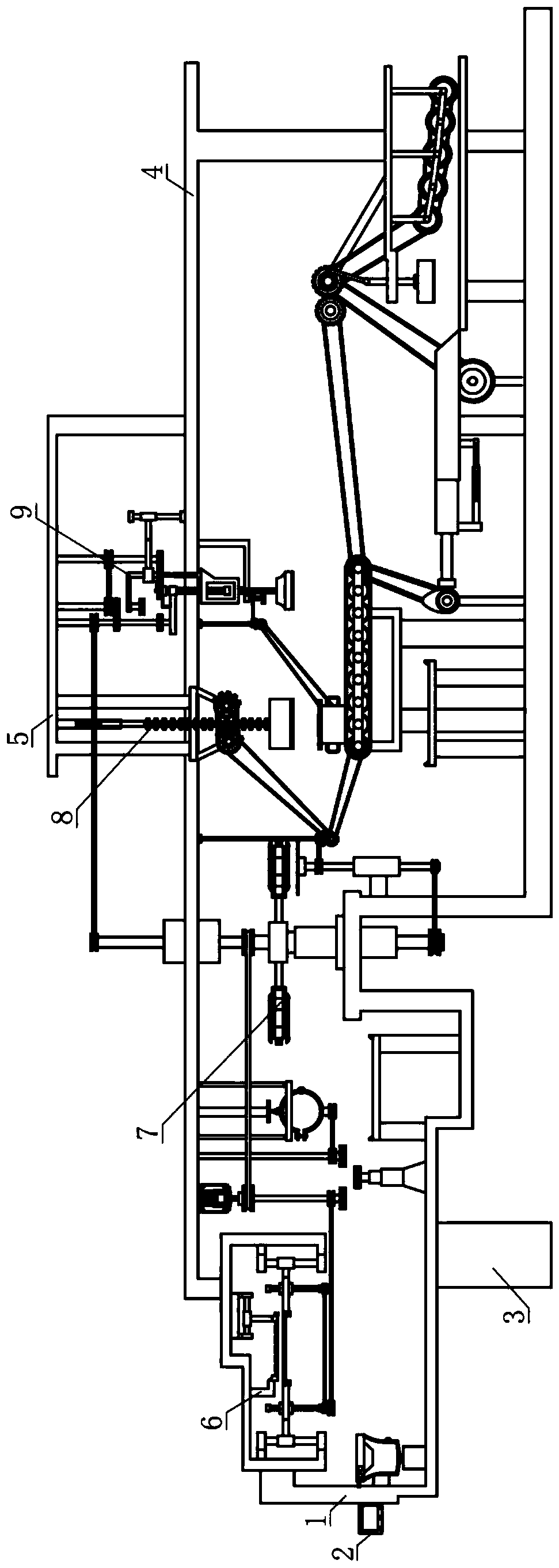

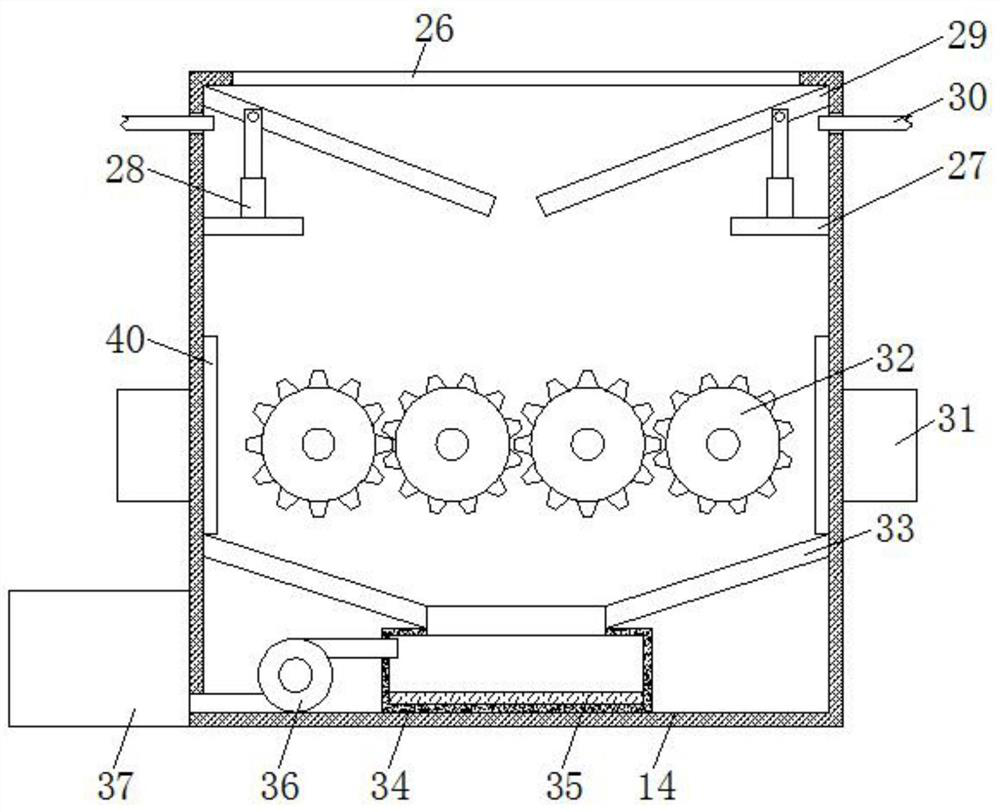

Method and equipment for recovering main reinforcing bar in concrete beam

ActiveCN112547752AIncrease profitImprove recycling ratesSolid waste disposalGrain treatmentsConcrete beamsArchitectural engineering

The invention relates to a method and equipment for recovering a main reinforcing bar in a concrete beam. The method comprises the following steps of first, crushing the concrete beam by using a crusher; then further rolling and crushing the concrete beam by a rolling crusher and clipping a stirrup; outputting the crushed concrete blocks and clipped stirrups by a waste output machine in a centralized manner; and finally, clipping the main reinforcing bar cleaned by the main reinforcing bar clipping machine as needed and covering the main reinforcing bar in a centralized manner, wherein the utilization ratio is improved. By adopting automatic equipment, the main reinforcing bar with the highest recycling value in the concrete beam is crushed and dismantled efficiently and are clipped in a centralized manner, so that the main reinforcing bar is recycled efficiently and therefore, the recycling rate of the concrete beam is improved. The equipment for recovering the main reinforcing bar inthe concrete beam is designed by using modular equipment, and is convenient to manufacture and assemble and convenient and reliable to maintain daily.

Owner:JIANGSU HUAHONG TECH STOCK

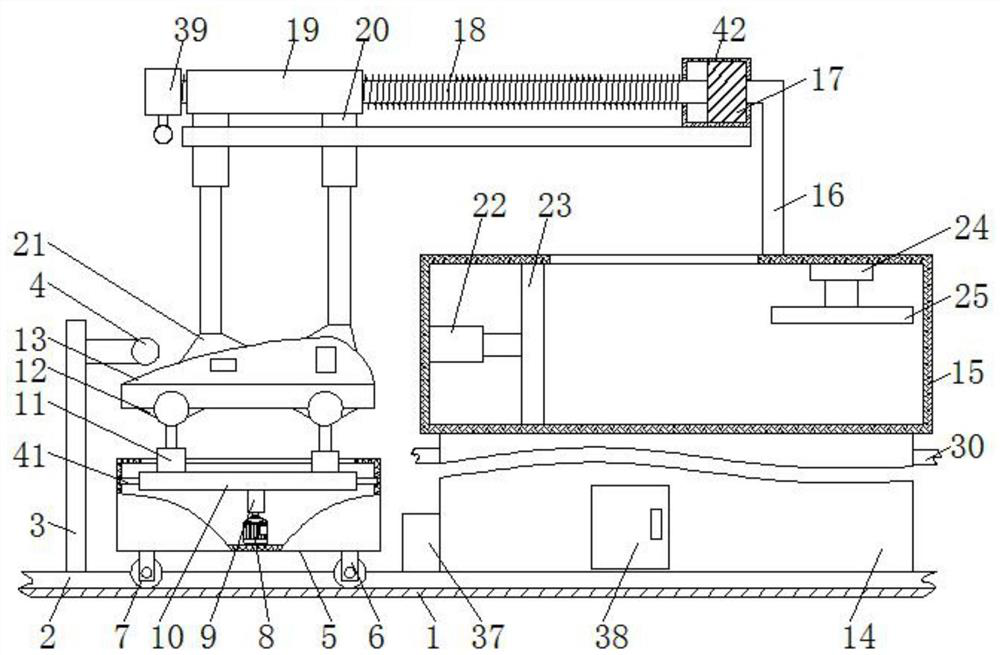

One-stop type disassembling process for small-sized automobile

ActiveCN108749960ASolve the problem of low disassembly efficiencyEfficient disassemblyVehicle dissasembly recoverySolid waste disposalMagnetic separatorAgricultural engineering

The invention discloses a one-stop type disassembling process for a small-sized automobile. The one-stop type disassembling process for the small-sized automobile comprises slide rails; the number ofthe slide rails is two; and slide grooves are formed in the tops of the slide rails. According to the one-stop type disassembling process for the small-sized automobile, through coordination of a cutting frame, a cutting device, an adjusting frame, rolling wheel carriers, rolling wheels, a motor, a rotating shaft, a rotating disc, a first electric telescopic rod, a first fixing disc, a treatment box, a compression box, a supporting frame, a second motor, a threaded rod, a threaded sleeve, first hydraulic rods, second fixing discs, a second hydraulic rod, a first extrusion plate, a third hydraulic rod, a second extrusion plate, driving mechanisms, crushing rollers, discharging inclined plates, a screening box, a magnetic separator, a fan, an article storage box and a material fetching device, the problem that the disassembling efficiency of the traditional one-stop type disassembling process for the small-sized automobile is low is solved; and the one-stop type disassembling process forthe small-sized automobile has the advantages that the disassembling is efficient, time and labor are both saved during disassembling, the disassembling effect is good, and the disassembling efficiency is greatly enhanced.

Owner:广东拓展资源综合利用开发有限公司

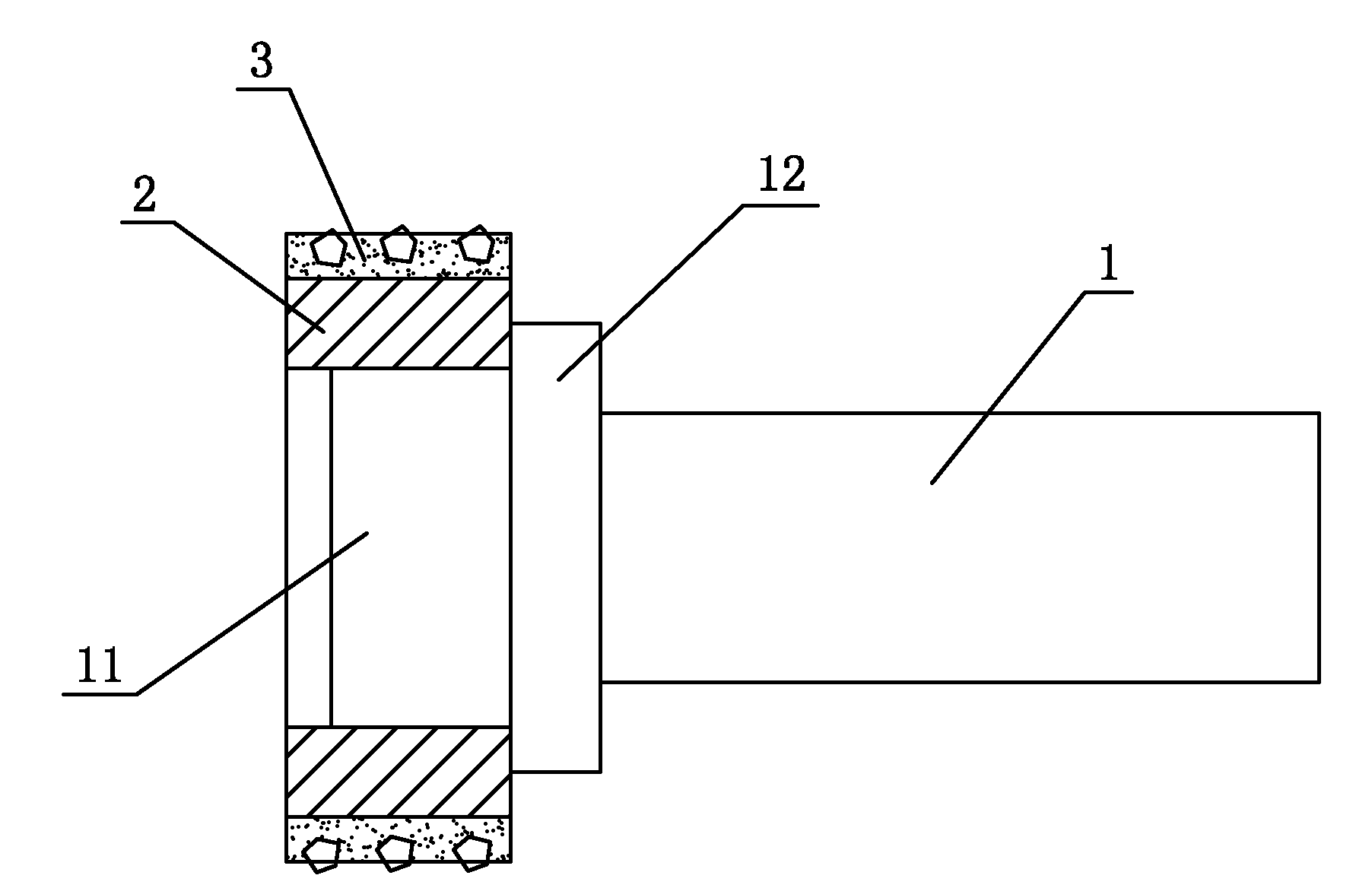

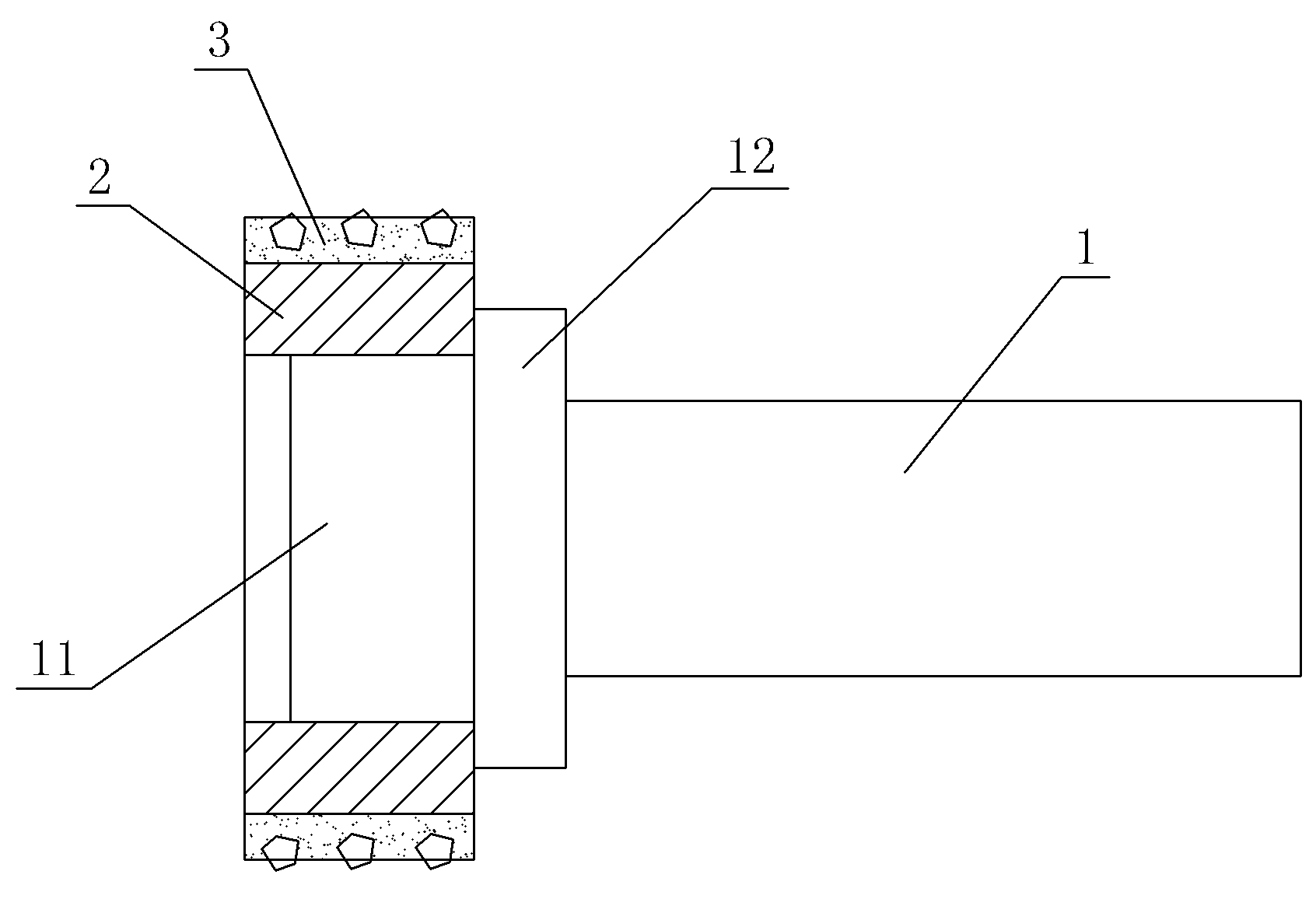

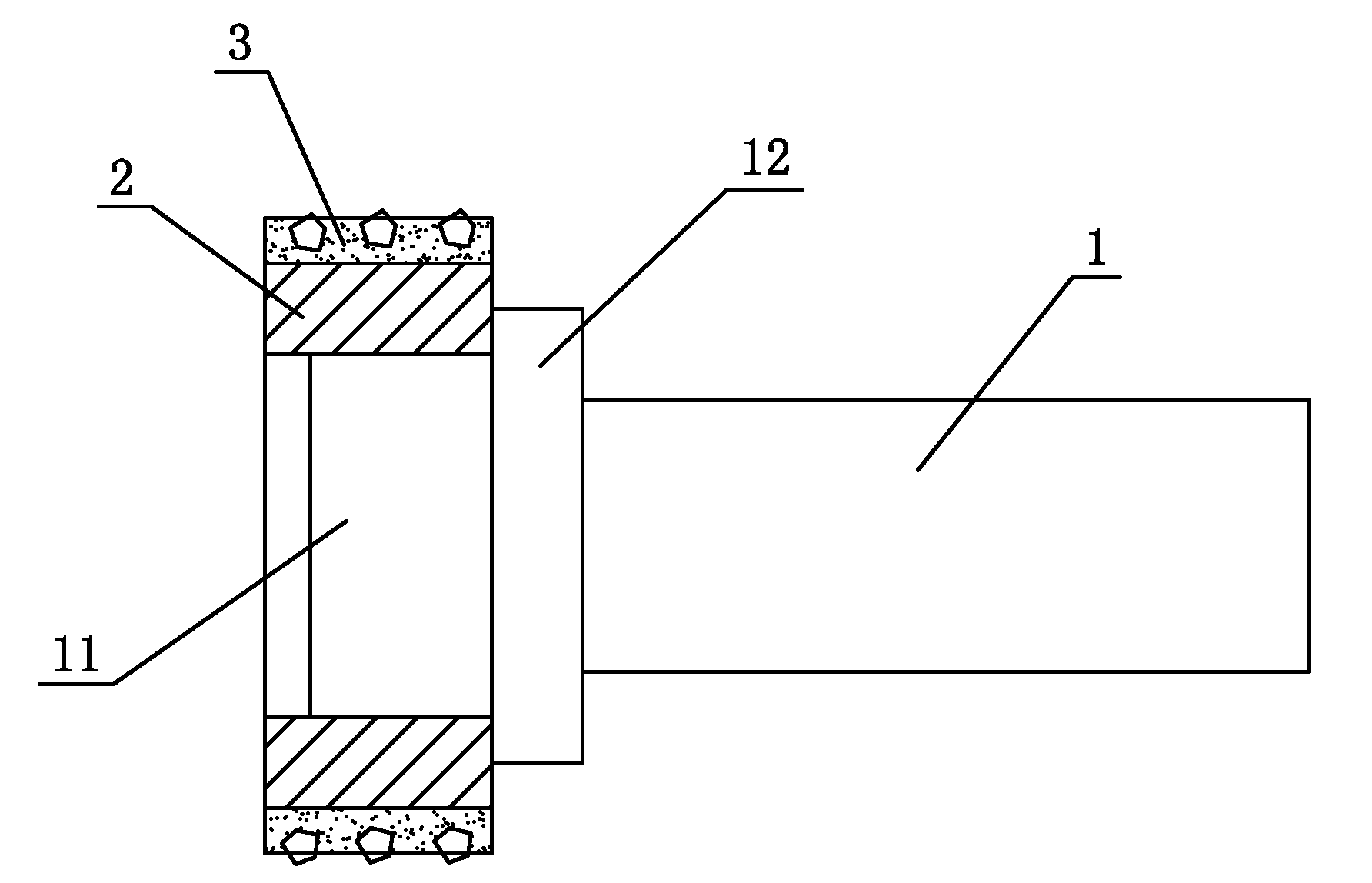

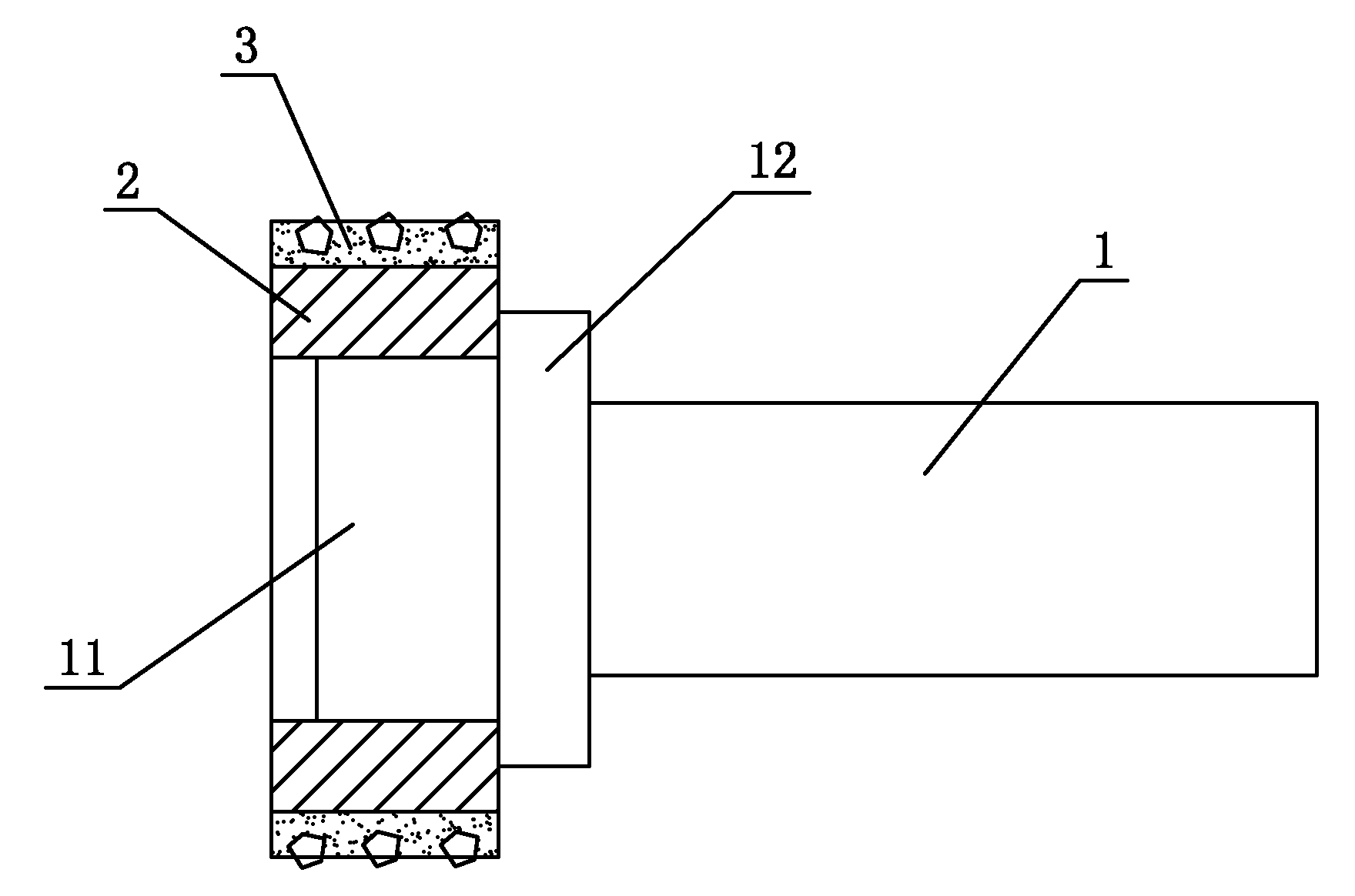

Easily recovered electroplated diamond grinding wheel

InactiveCN101934502AEasy to break awayQuick disassemblyBonded abrasive wheelsInterference fitMicro gap

The invention discloses an easily recovered electroplated diamond grinding wheel. The grinding wheel comprises a matrix and a diamond grinding material layer, and is characterized in that: the matrix is provided with a connecting part which is in interference fit with an auxiliary matrix; and the diamond grinding material layer is electroplated on the outer surface of the auxiliary matrix. The grinding wheel has the advantages that: when extruded by the connecting part in a connecting state, the auxiliary matrix is in an elastic expansion and deformation state; in the process of recovering the grinding wheel, the auxiliary matrix is not in the elastic deformation state any more when removed from the connecting part, so that micro gaps are formed between the diamond grinding material layer and the auxiliary matrix, the diamond grinding material layer is easily separated from the surface of the auxiliary matrix, the quick and high-efficiency separation of the diamond grinding material layer from the matrix is realized, and the electroplated diamond grinding wheel is recovered more conveniently and easily.

Owner:NINGBO UNIV

Manufacturing method of easily recoverable electroplated diamond grinding wheel

The invention discloses a manufacturing method of an easily recoverable electroplated diamond grinding wheel, which has the advantages that: in the electroplated diamond grinding wheel manufactured by the method, due to the clearance connection of an auxiliary substrate and the connecting part and the electroplating of a diamond grinding material layer on the outside surface of the auxiliary substrate, the auxiliary substrate in a connected state is kept into an elastic expansion deformation state by the squeezing of the connecting part and, in a grinding wheel recovery process, is detached from the auxiliary substrate and restored from the elastic deformation state and forms a micro gap with the diamond grinding material layer to allow the diamond grinding material layer to separate from the surface of the auxiliary substrate easily; and thus, the diamond grinding material layer is detached from the substrate quickly and efficiently, and the recovery of the electroplated diamond grinding wheel is convenient and easy.

Owner:NINGBO UNIV

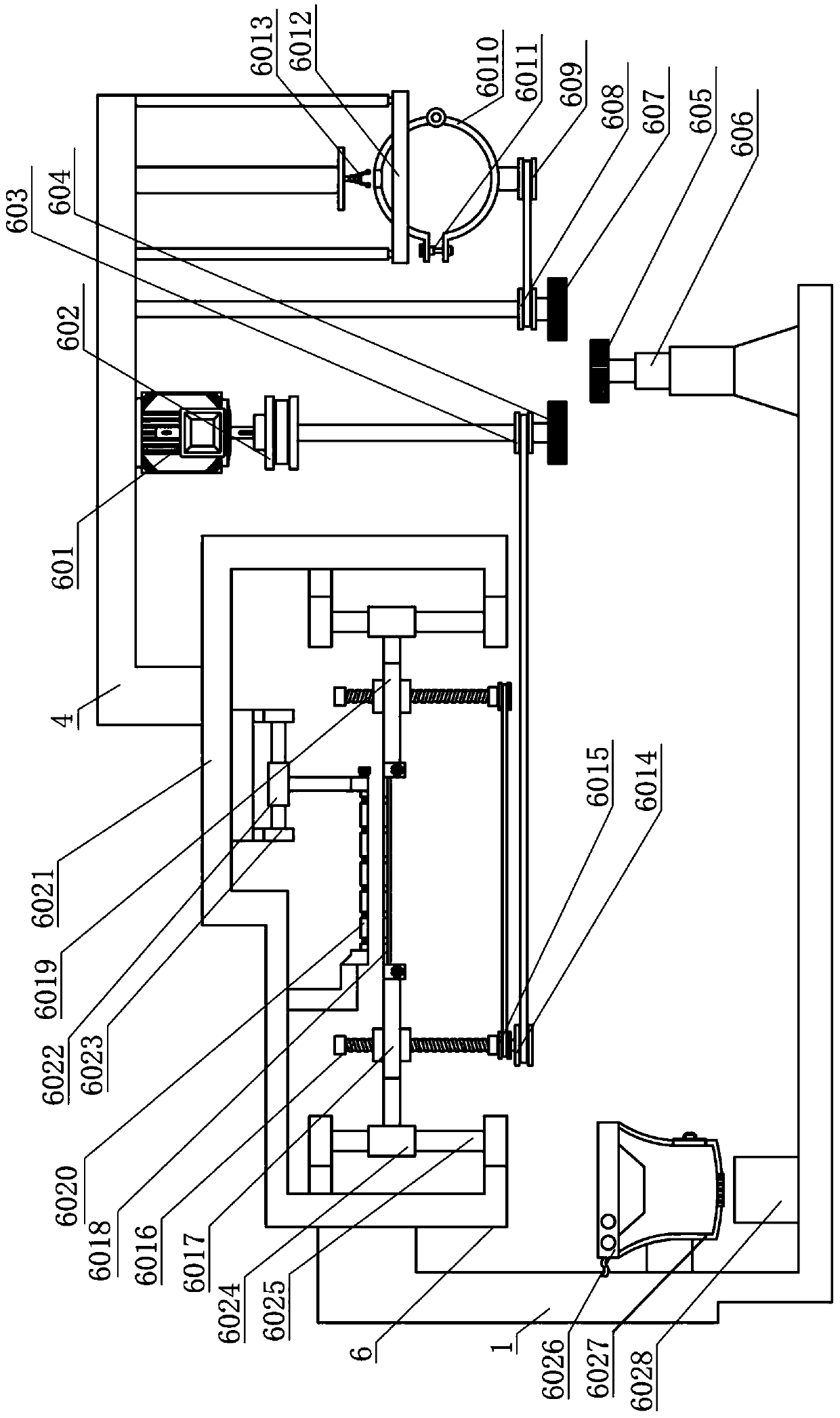

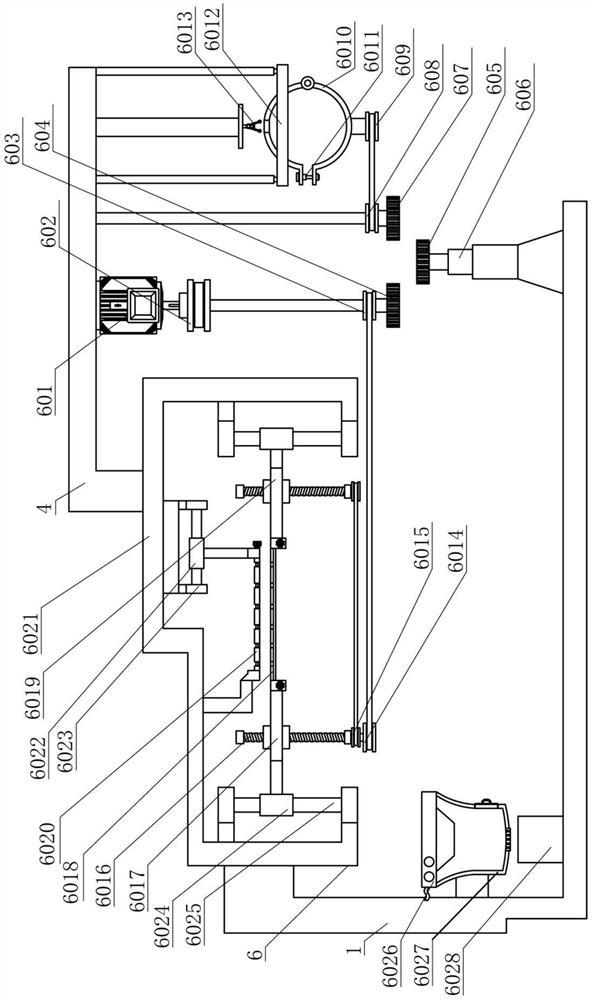

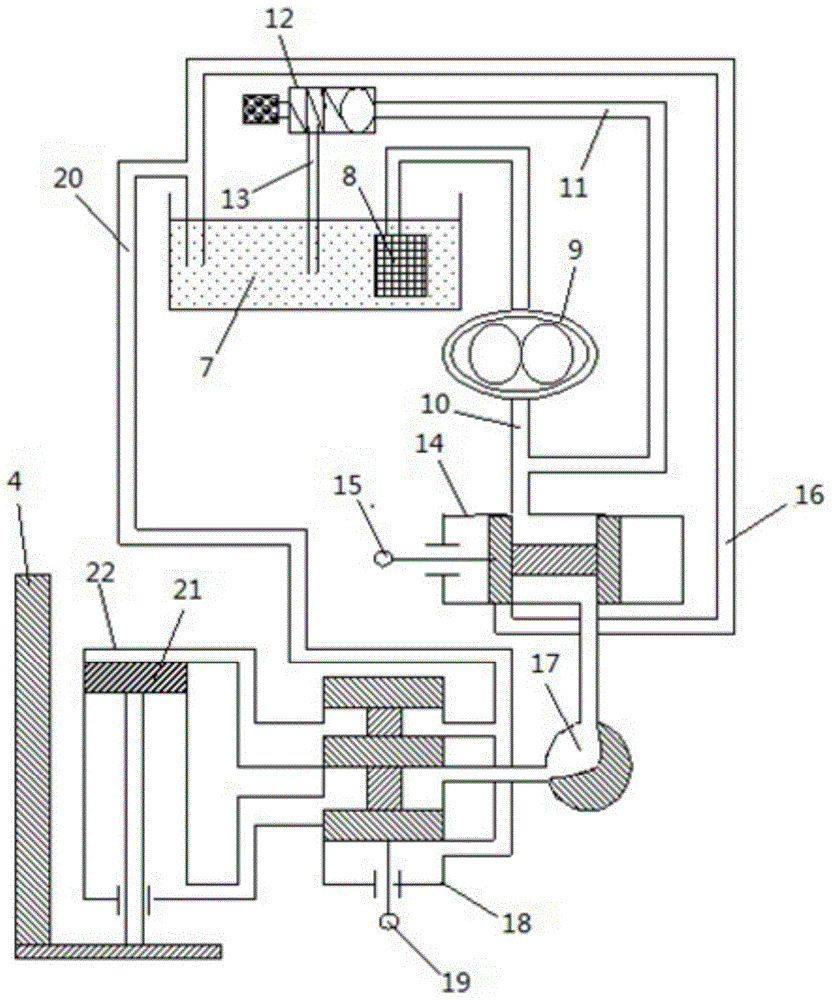

Stainless steel metal recovery device

ActiveCN111250509APrecise resectionEfficient dismantlingGrinding carriagesSolid waste disposalMetal recyclingEngineering

The invention relates to a metal recovery device, in particular to a stainless steel metal recovery device. The technical problem to be solved by device is to provide a stainless steel metal recoverydevice. The stainless steel metal recovery device comprises a bottom connecting frame, an operation control screen, supporting bottom feet, a top connecting frame, a middle top fixing frame, a handledisassembling mechanism, a bottom face cutting mechanism, a curled edge removing mechanism and a curled sheet separating mechanism; the operation control screen is arranged at the middle-lower part ofthe left end of the bottom connecting frame; the left side of the bottom end of the bottom connecting frame is connected with supporting bottom feet; the right side of the top of the bottom connecting frame is connected with the top connecting frame; and the handle disassembling mechanism is arranged on the left side in the bottom connecting frame. According to the device, the effects of disassembling and separating the handle and the stainless steel cylinder body at a high speed, accurately cutting off the bottom panel of the wrinkled cylinder body, finally efficiently cutting off the curlededge of the stainless steel rice cylinder and cutting and compacting the curled edge into a plate to obtain a stainless steel recycled plate are achieved.

Owner:佛山市敏瑞电器制品有限公司

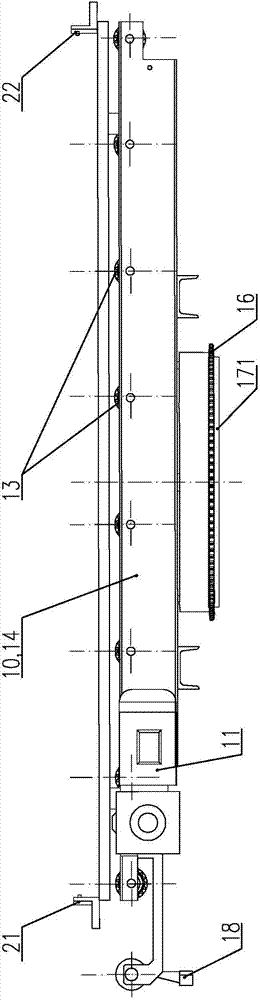

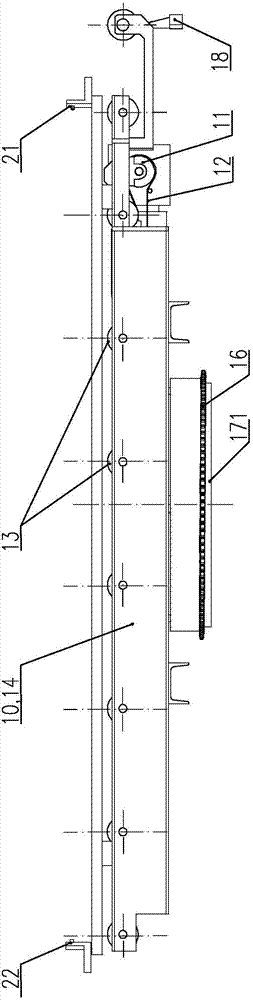

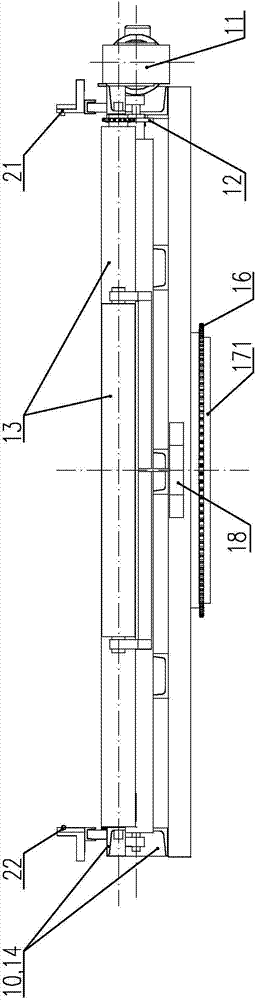

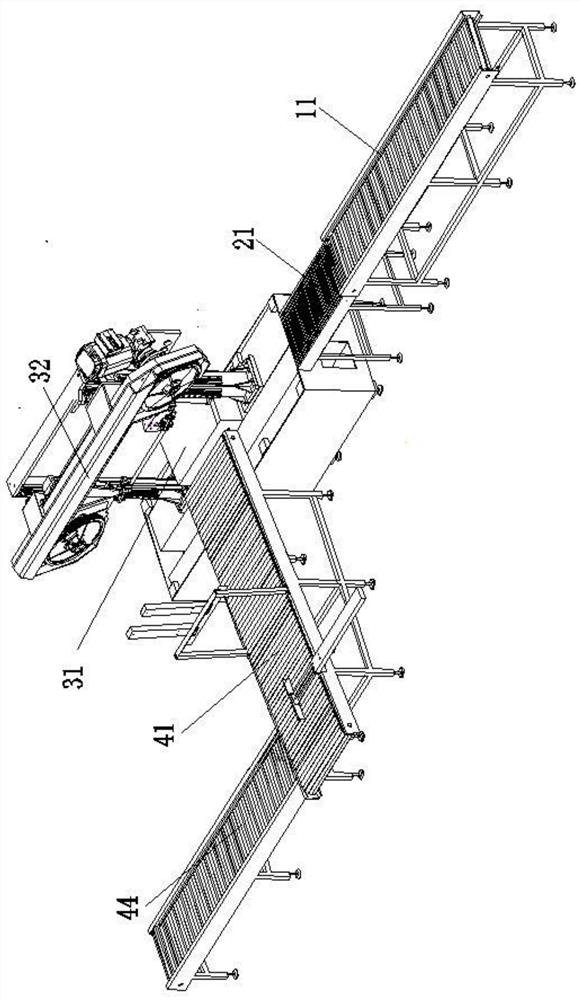

Multilayer-roller-bed steering machine and tree type roller bed conveying system of dismantling industry thereof

ActiveCN103523448ADoes not affect disassemblyEfficient dismantlingPackagingMechanical conveyorsElectric machineryMachine

The invention relates to a multilayer-roller-bed steering machine and a tree type roller bed conveying system of the dismantling industry thereof. The multilayer-roller-bed steering machine comprises a base and roller bed sections. The base comprises n layers of frames, and the edge portion of the frame of each layer is provided with a steering motor with a driving chain wheel and a limiting stopper. The steering machine comprises corresponding n layers of roller bed sections, the lower face of the middle portion of the roller bed section of each layer is connected with a driven chain wheel and a steering bearing and is in rotating fit with the upper face of the middle portion of the frame of each layer, the edge portion of the roller bed section of each layer is provided with a trigger block corresponding to the limiting stopper on the frame of each layer, the driven chain wheels are connected with the driving chain wheels on the frames of all layers through steering chains, and the upper portion of the roller bed section of each layer is provided with a material sensor for detecting materials. On the premise of reducing dismantling occupied area, conveying roller beds with multiplied length and the roller bed conveying system with doubled tree type join numbers are set up, economic and social benefits of abandoned automobile and electric appliance dismantling enterprises are substantially improved, and a novel way is provided for development and expansion of the abandoned automobile and electric appliance dismantling enterprises.

Owner:WUHAN GEM URBAN MINE EQUIP +3

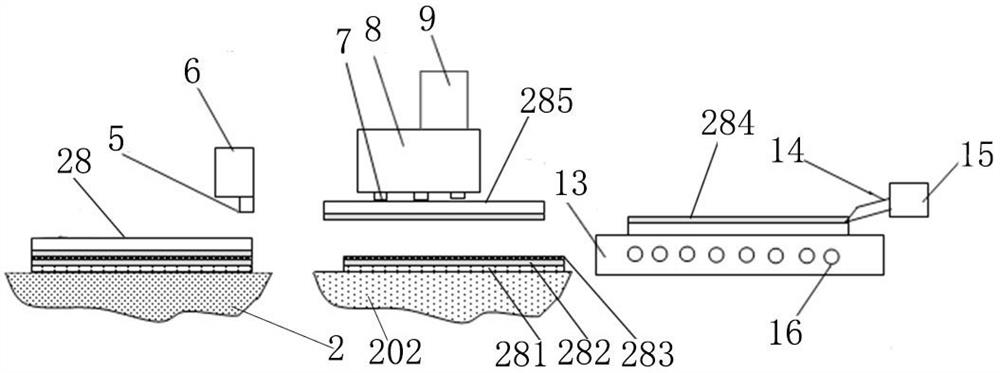

Equipment and method for disassembling solar cell module

ActiveCN112058871ARealize environmental protectionRealize sorting and recyclingWaste processingSolid waste disposalPhysicsSilicon chip

The invention provides equipment and a method for disassembling a solar cell module. The equipment for disassembling the solar cell module comprises a laser scanning device, a first collecting and conveying device, a hot knife device, a low-temperature processing device, a second collecting and conveying device, a rolling device and a separating device. According to the equipment and the method for disassembling the solar cell module provided by the invention, glass and an upper cover ethyl vinyl acetate (EVA) film adhered to the glass are disassembled from the solar cell module through the laser scanning device, and the glass and the upper cover EVA film adhered to the glass are separated through the hot knife device, so that the complete glass is obtained. Then through a low-temperatureenvironment manufactured by a low-temperature processing device under normal pressure, a complete backboard, a complete laid EVA film and a cell of the solar cell module are obtained. According to theequipment and the method for disassembling the solar cell module provided by the invention, the cells are crushed through the rolling device so as to obtain silicon wafer particles, metal welding strips and metal busbar, and different materials are separated and sorted through the separating device, so that the environment-friendly disassembling and the classified recycling of waste solar cell modules are achieved.

Owner:HEBEI UNIVERSITY

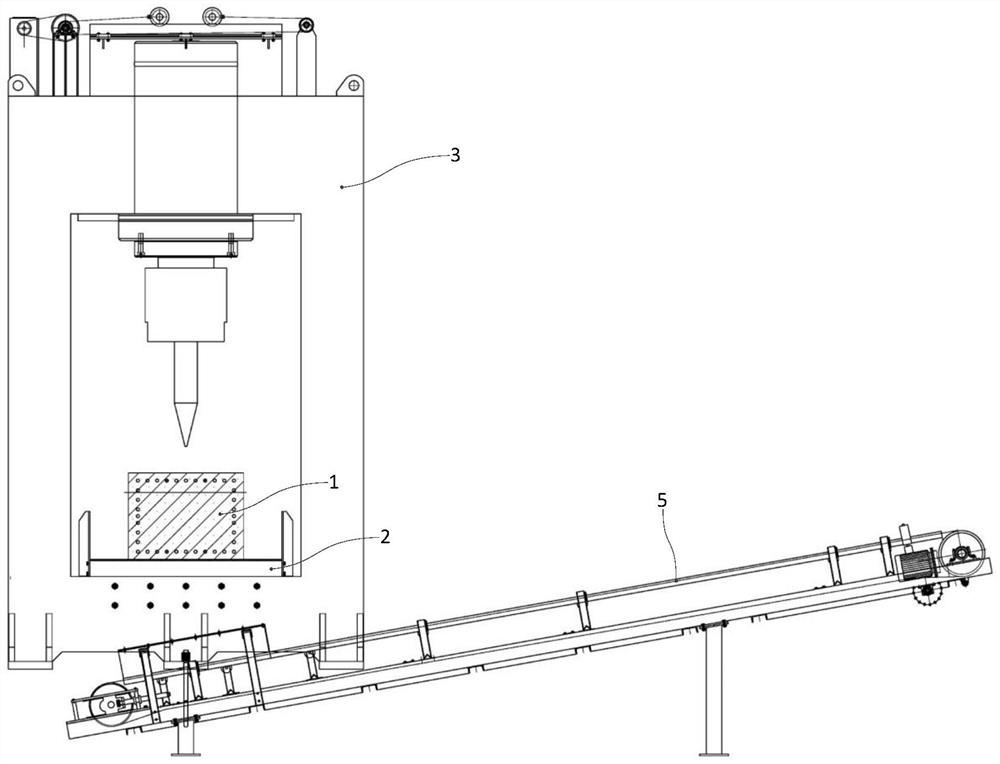

Green automatic dismantling device and method for waste tires

PendingCN109332356AEfficient dismantlingDisassembly safetySolid waste disposalGripping headsPollutionWaste tires

The invention discloses a green automatic dismantling device for waste tires. The device comprises a loading and unloading device, an extrusion device, a fixed feeding device and a visual control device; when scrapped tires are recycled, the loading and unloading device is used for finishing loading and unloading of the waste tires; the fixed feeding device is used for fixing, rotating, adjustingand feeding of the tires; the waste tires are extruded and compressed by utilizing the extrusion device, so that rims are crushed or extruded and deformed; the visual control device is used for monitoring working conditions of each device and monitoring deformation amount of positioning and compression of the tires; and finally the device enables the rims and the rubber tires to be completely separated and classified and recycled, so that the dismantling of the waste tires is guaranteed to be efficient, safe and pollution-free. According to the device, the tires with different specifications and different materials can be scrapped according to different vehicle types, rapid, safe and reliable dismantling of the tires can be realized, classification and recycling after dismantling are facilitated, so that the device has strong adaptability and utilization value.

Owner:JIANGSU UNIV OF TECH

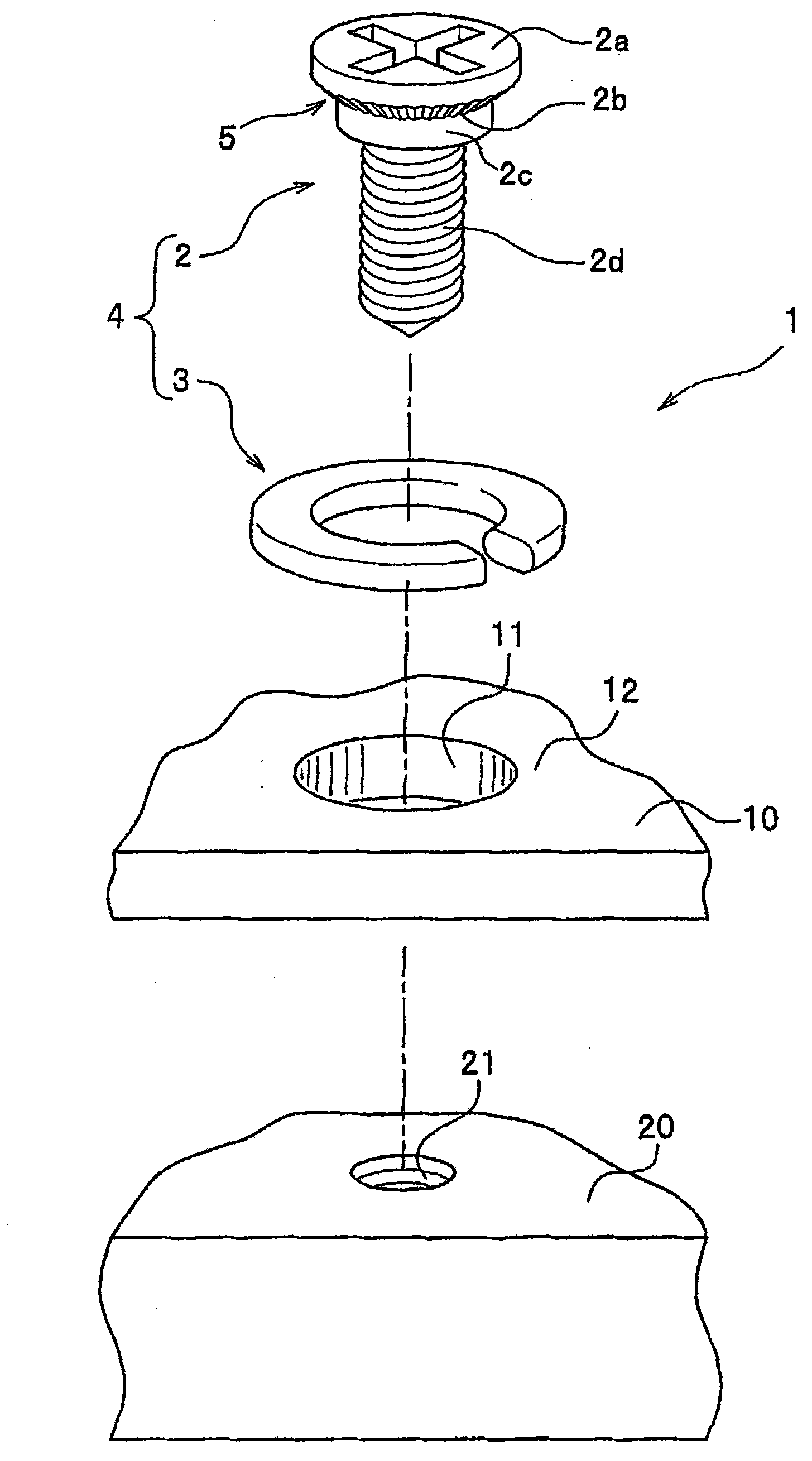

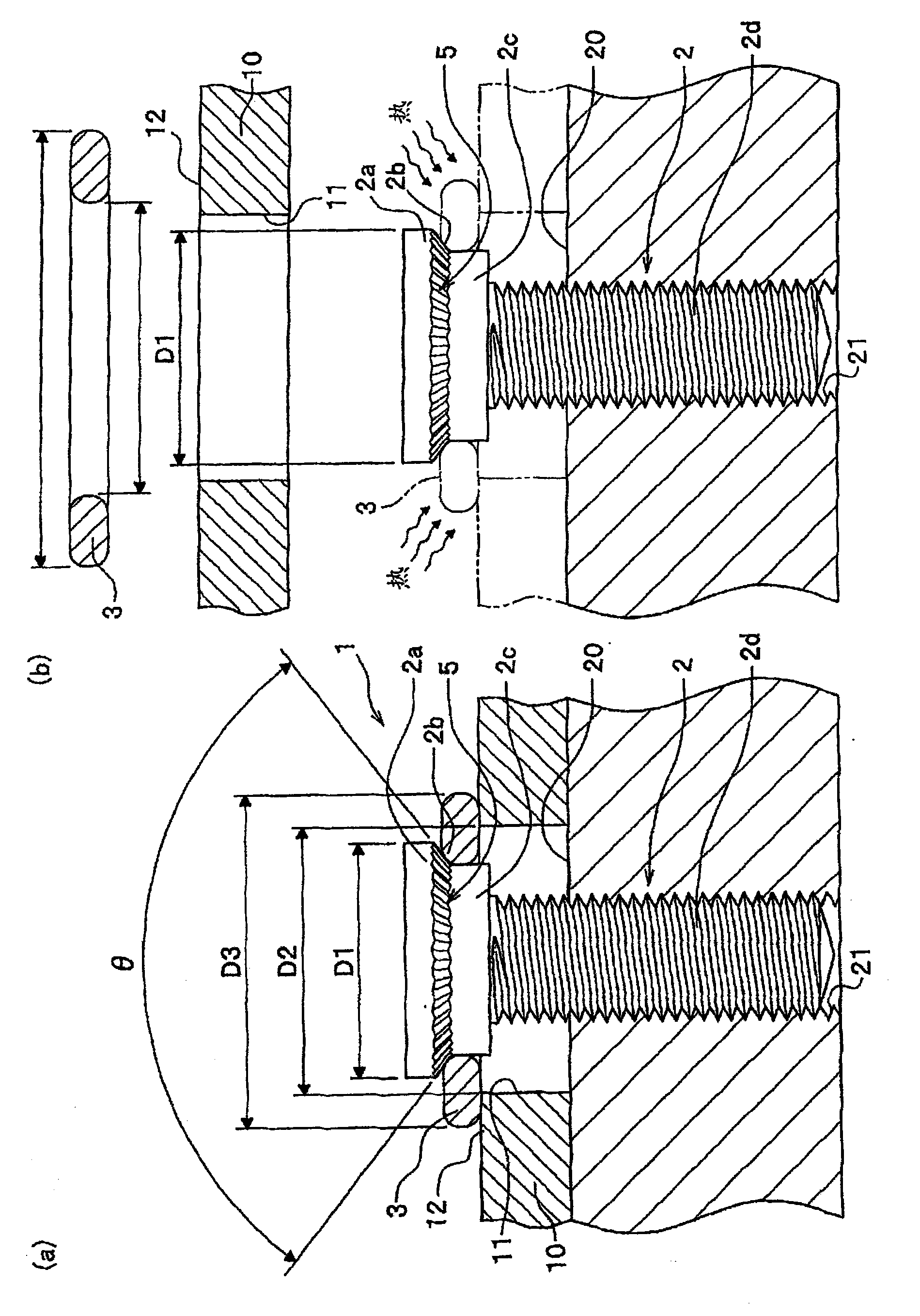

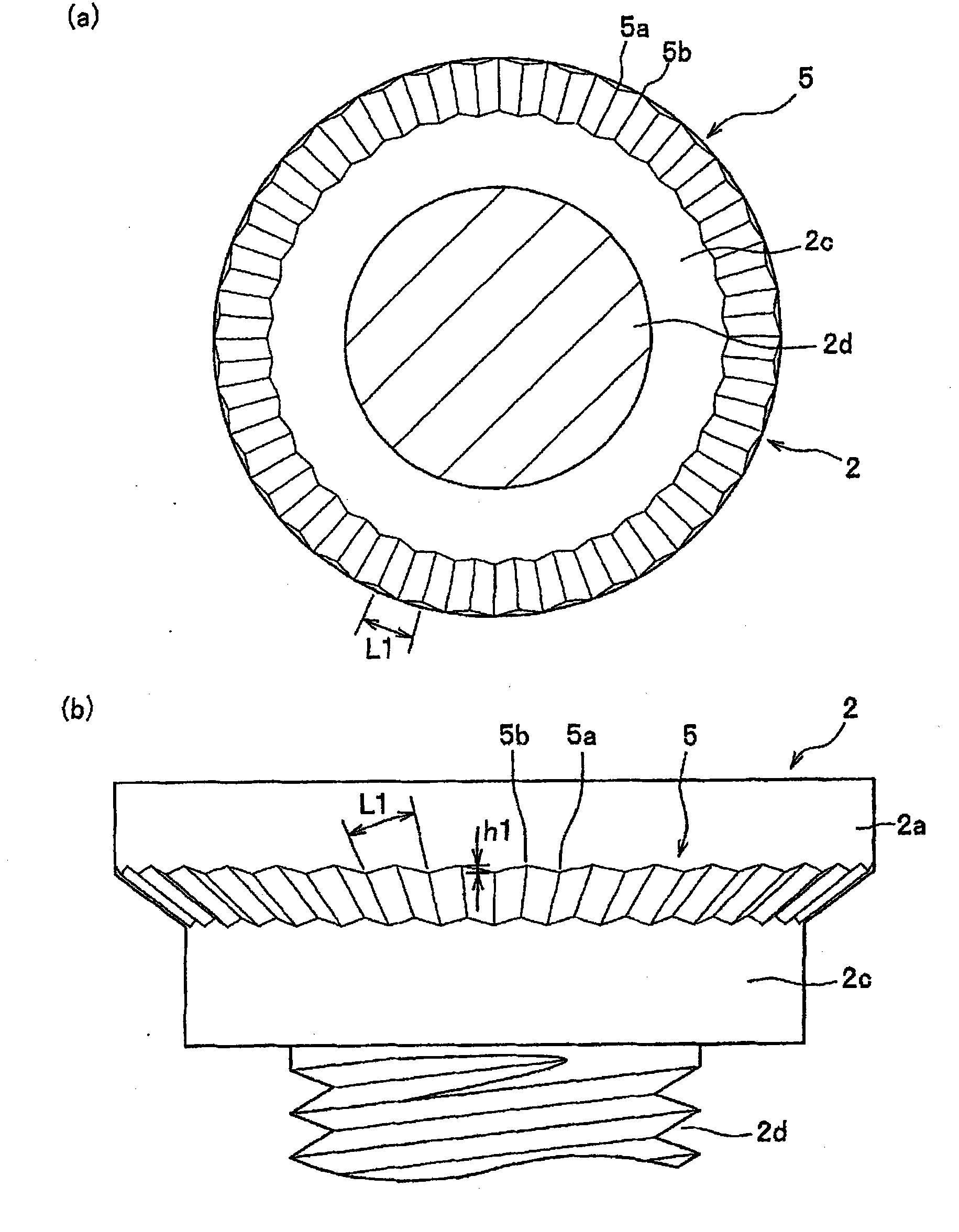

Fastening body structure

A fastening body structure having a screw member which uses a module screw having a countersunk head and also uses, together with the module screw, a washer made of a shape memory alloy. With this structure, the washer does not expand even if subjected to large fastening force in fastening of a part to be fastened and in which the washer can be easily removed when the screw fastening is released. The fastening body structure (1) fastens and fixes a desired part (10) to the installation section (20) by using the screw member (4) having the module screw (2) and the shape memory alloy washer (3). The module screw (2) has a male screw (2d) used as a pair with a female screw thread section (21) formed in the installation section (20), and also has the countersunk head (2a). The shape memory alloy washer (3) has an inner diameter corresponding to the module screw. An irregular surface section (5,(50)) is formed on a slope surface at the lower part of the head of the module screw or on that surface of the washer which makes contact with the screw.

Owner:TOKAI UNIV

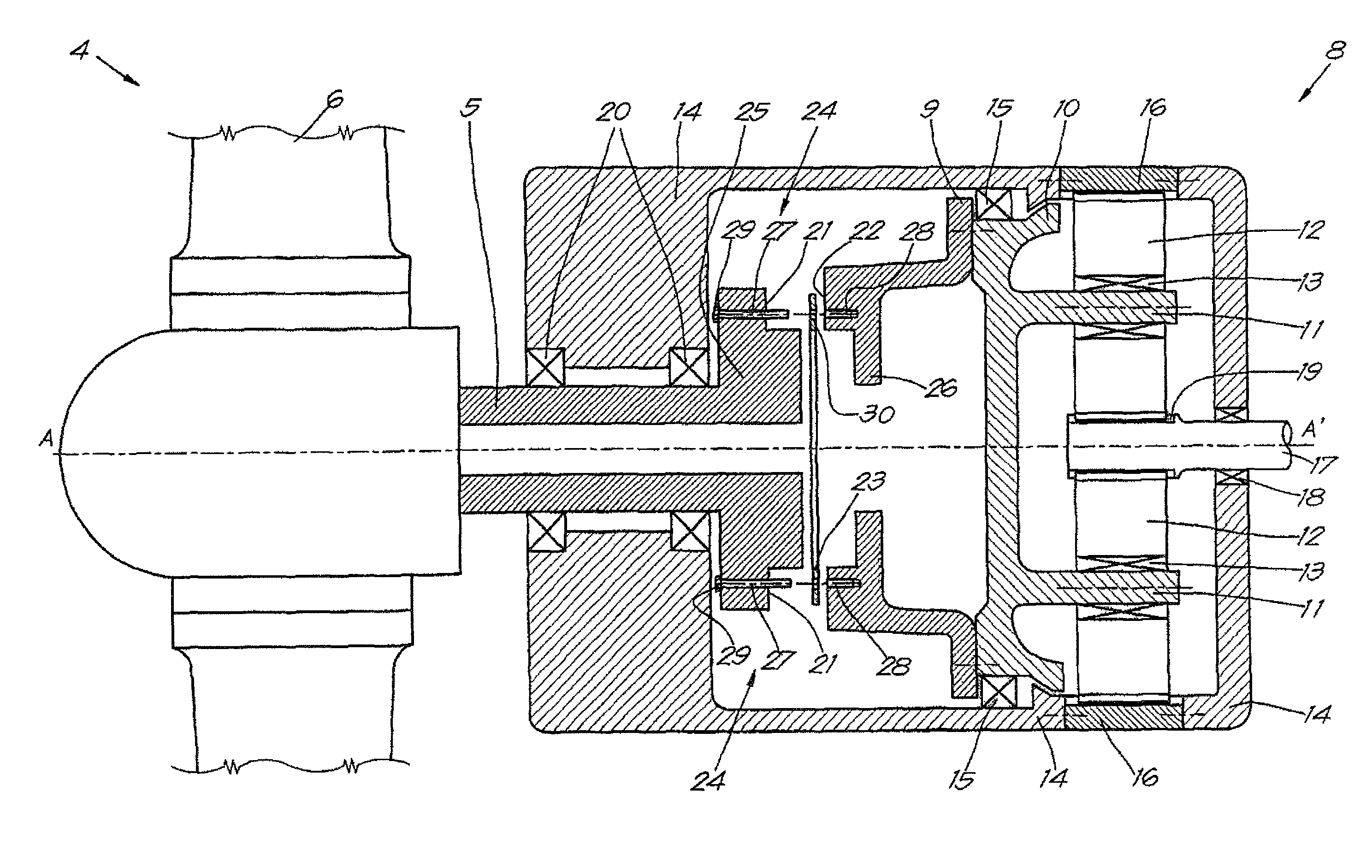

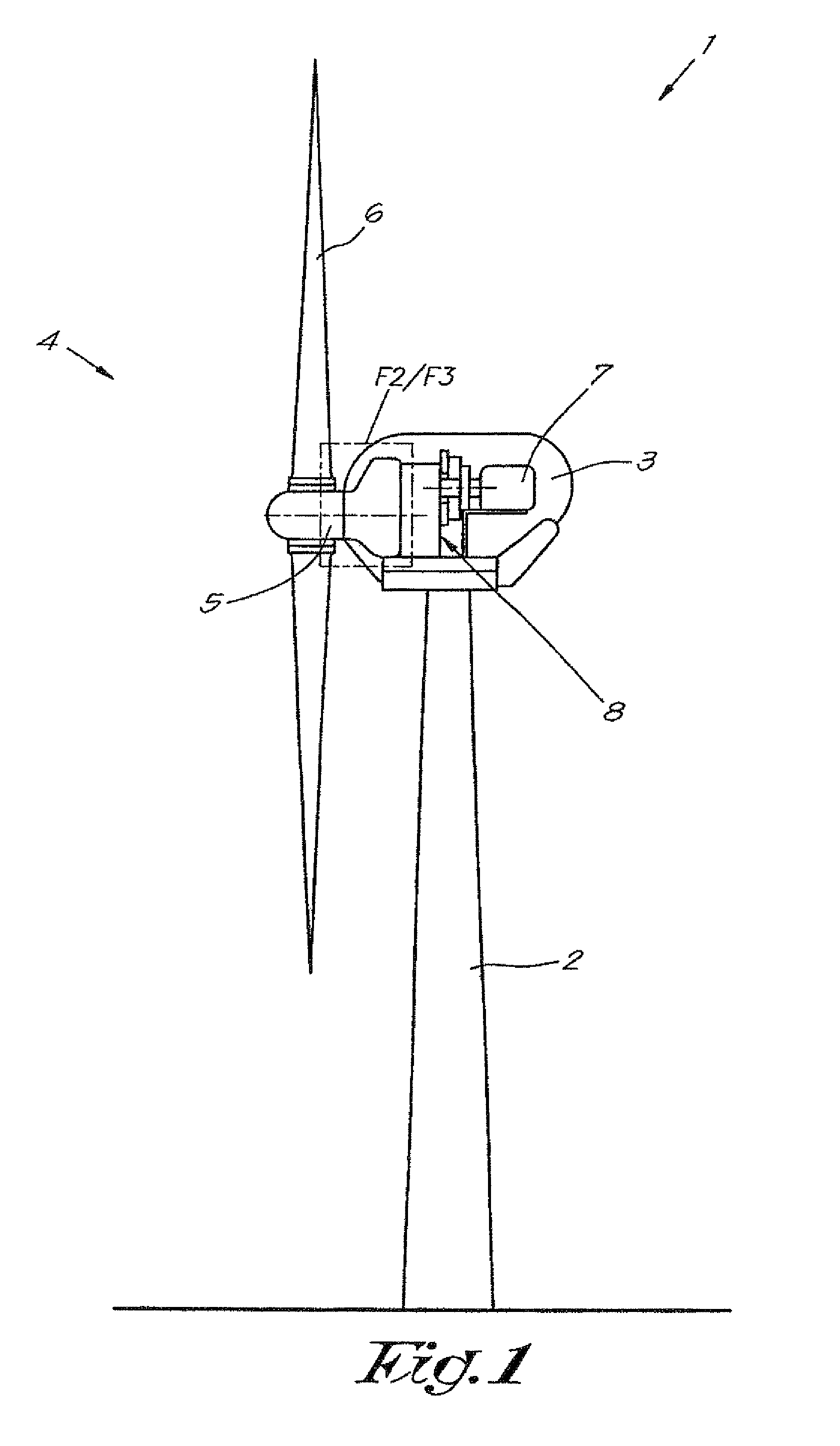

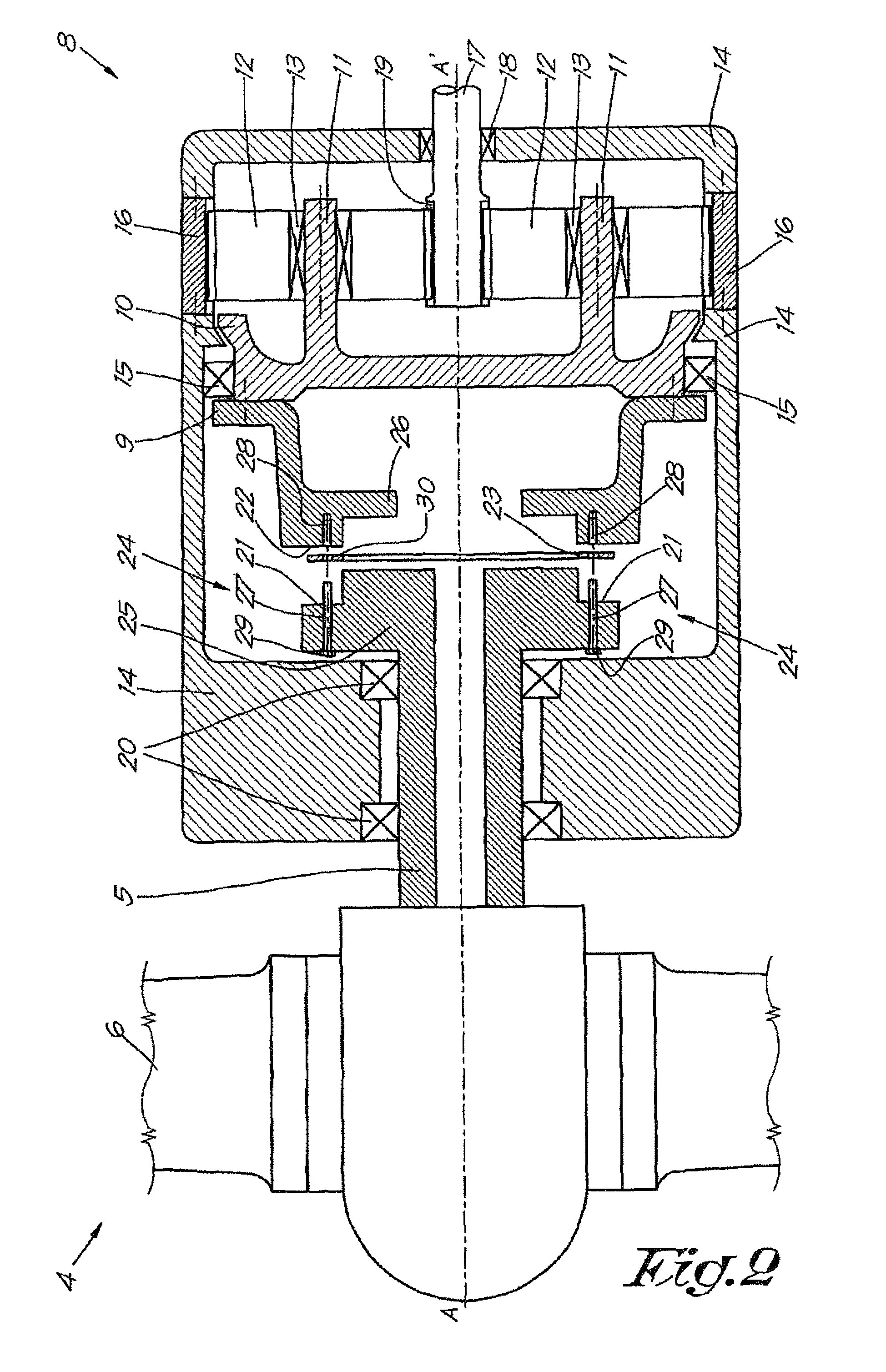

Method for connecting a low speed main shaft of a wind turbine to an input shaft of a transmission gearbox of the wind turbine and a connection obtained by said method

InactiveUS8834120B2Increase coefficient of frictionImprove connection qualityPropellersFinal product manufactureLow speedTurbine

A method for connecting a low speed main shaft of a wind turbine to an input shaft of a transmission gearbox of the wind turbine is disclosed. The method includes providing a connection surface on the main shaft and a corresponding connection surface on the input shaft, placing a friction enhancing means on at least one of the connection surfaces, and firmly connecting both connection surfaces to one another, a permanent load being applied on the connection surfaces.

Owner:GAMESA INNOVATION & TECH SA +1

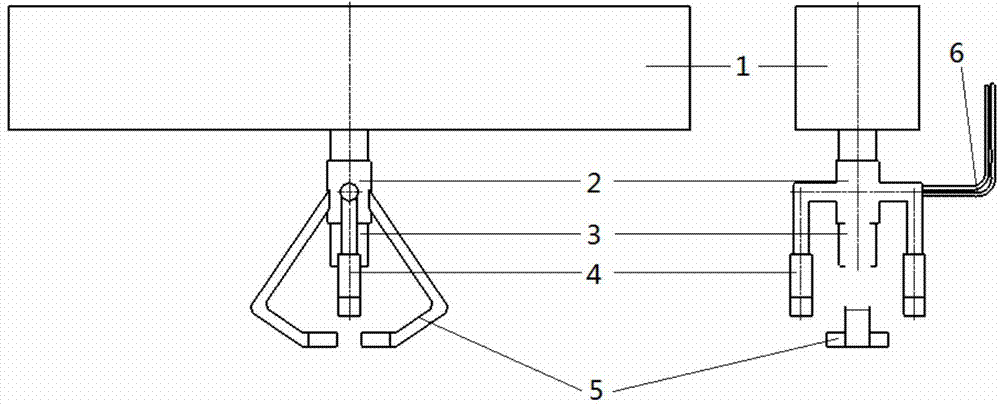

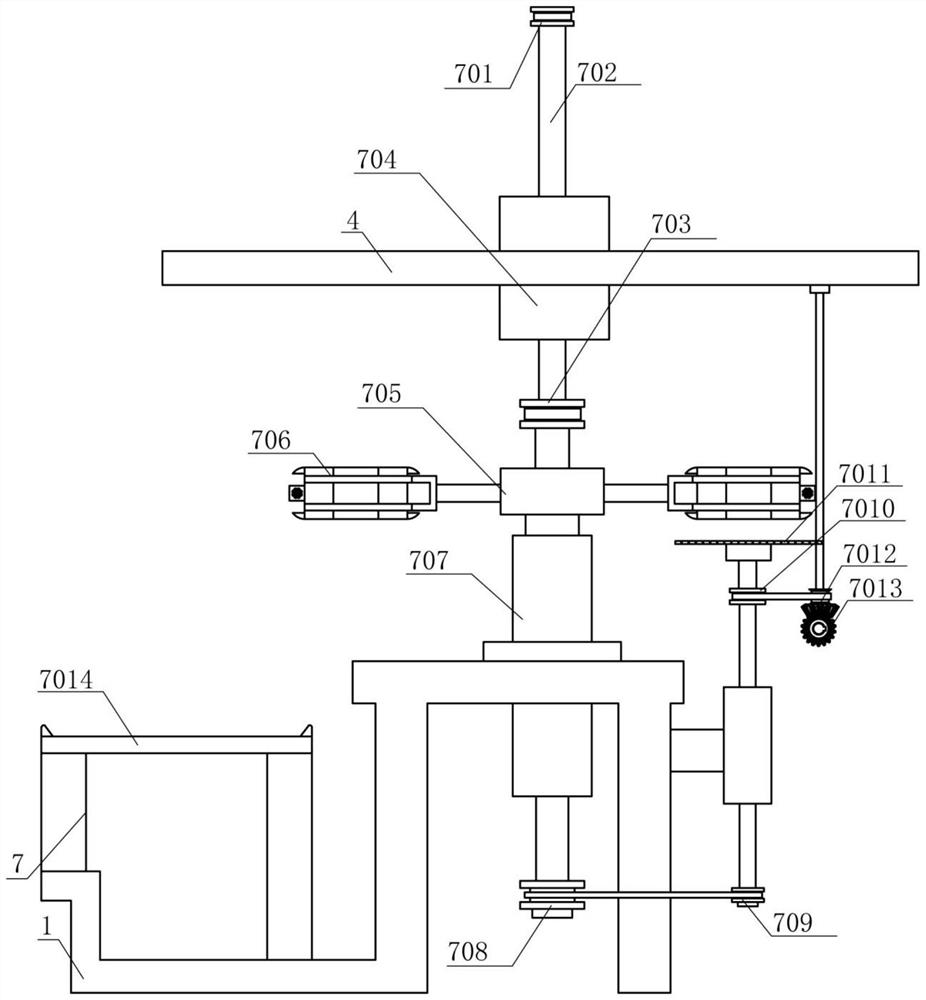

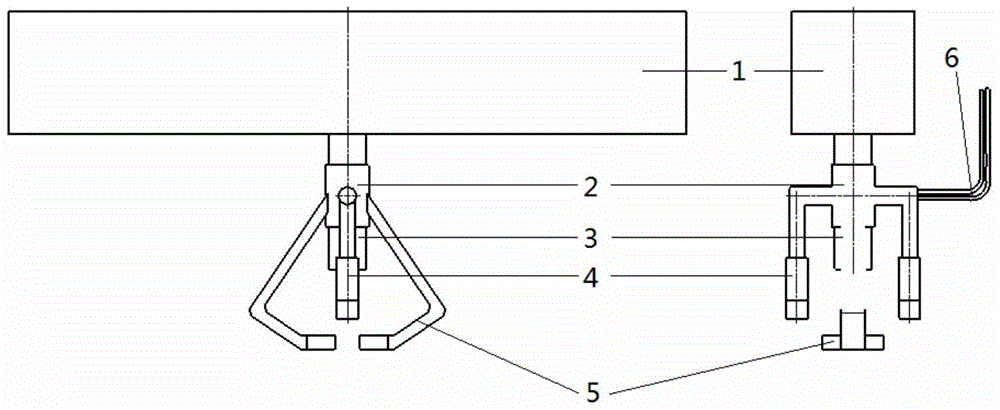

Auxiliary disassembly device for disassembly of differentials

InactiveCN104493471AConvenient centralized disassemblyMeet the technical conditionsProgramme-controlled manipulatorGripping headsHydraulic cylinderHydraulic pump

An auxiliary disassembly device for disassembly of differentials comprises a mechanical portion and a hydraulic control portion. The mechanical portion comprises a disassembly mechanism final-assembly frame, a lifting sleeve, a center shaft, a bolt disassembling spanner and a lifting mechanism mechanical claw. The hydraulic control portion comprises an oil tank, a hydraulic pump, a hydraulic loop pipeline, a control valve set and a hydraulic cylinder. Damage-free disassembly of the differentials is realized by combined motion of the mechanical portion and the hydraulic portion, the center shaft is used for positioning and limiting, the bolt disassembling spanner is used for disassembly, and the lifting mechanism mechanical claw is used for grabbing a differential left shell to complete separation. The auxiliary disassembly device for disassembly of the differentials has the advantages that the problems of high labor intensity, low efficiency, large damage and primitiveness of differential disassembly means in manufacturing are solved, disassembly tools are integrated, and high efficiency, excellent quality, energy saving, material saving and environment friendliness are achieved.

Owner:GUANGXI UNIV

Automatic disassembling line for waste lead-acid batteries

InactiveCN113571793ARealize dismantlingEfficient dismantlingLead-acid accumulatorsWaste accumulators reclaimingEngineeringProcess engineering

The invention discloses an automatic disassembling line for waste lead-acid batteries, which comprises a battery identification unit, a battery carrying unit, a battery cutting unit and a battery sorting unit, wherein the battery identification unit comprises a first conveying line and a battery model identification device, the battery carrying unit comprises a second conveying line and a turnover carrying manipulator, the battery cutting unit comprises a clamping device and a cutting device, and the battery sorting unit comprises a third conveying line, a battery cover identification device, a side pushing device, a fourth conveying line and a battery body vibrating screen. According to the invention, the battery is subjected to model identification in advance, corresponding carrying data, clamping data and cutting data are given on the basis of a database, battery cutting is accurately achieved, the recovery rate of battery lead and oxide of the battery lead is increased, modular design is adopted, work such as identification, clamping, disassembly and vibration separation of the battery is more efficiently achieved, and the problems of great damage, high pollution and the like caused by manual disassembly are solved.

Owner:无锡洛希极限科技有限公司

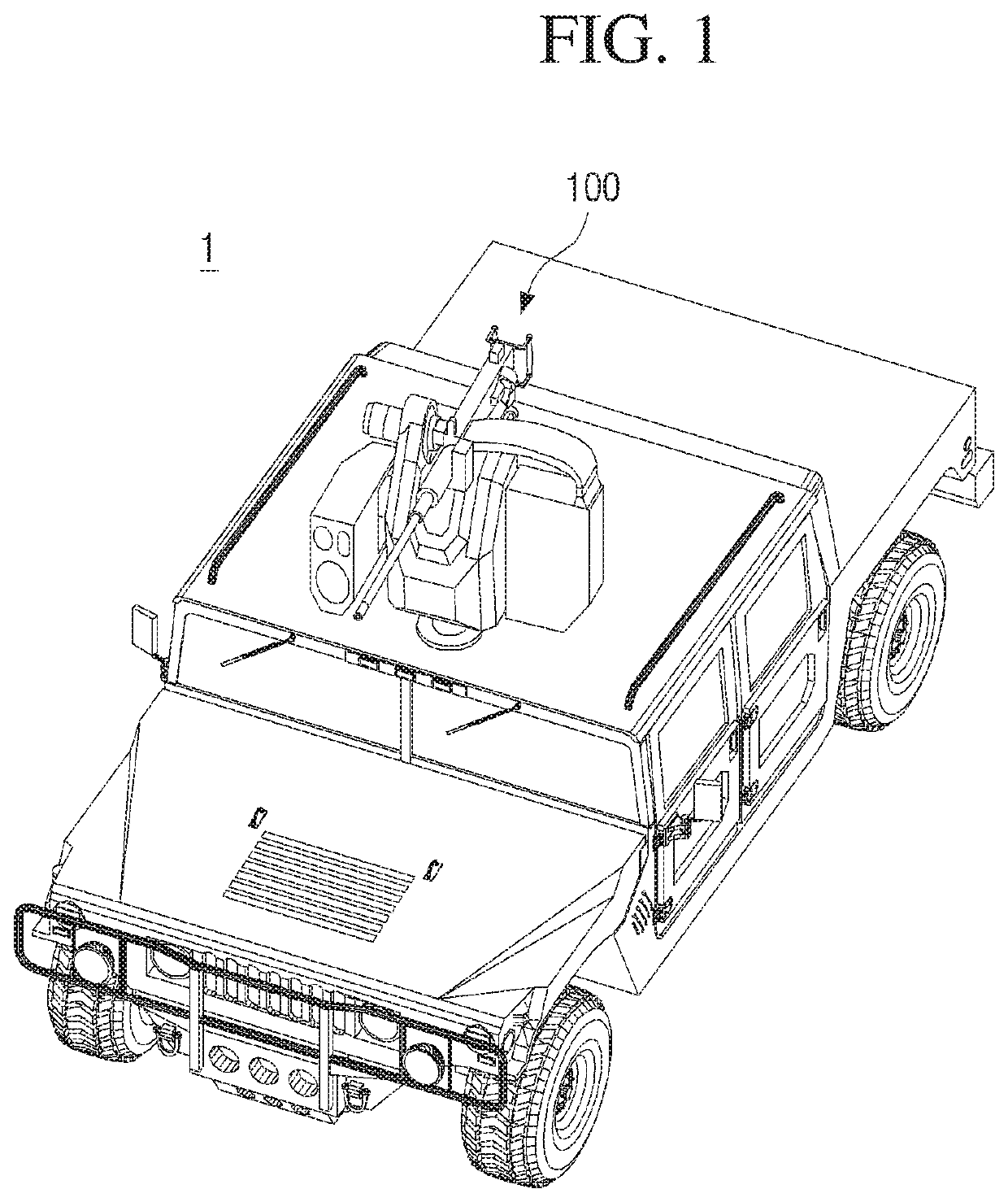

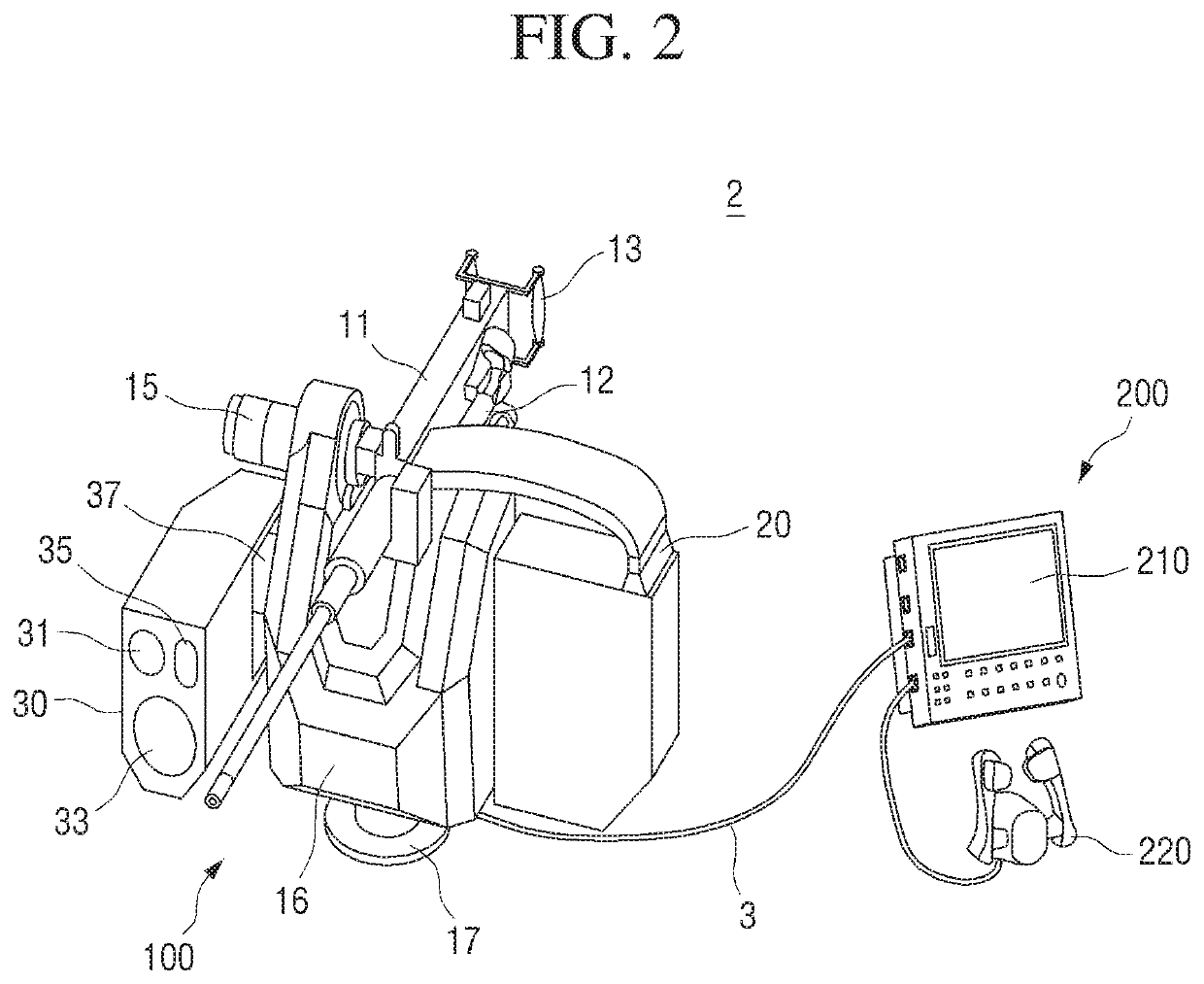

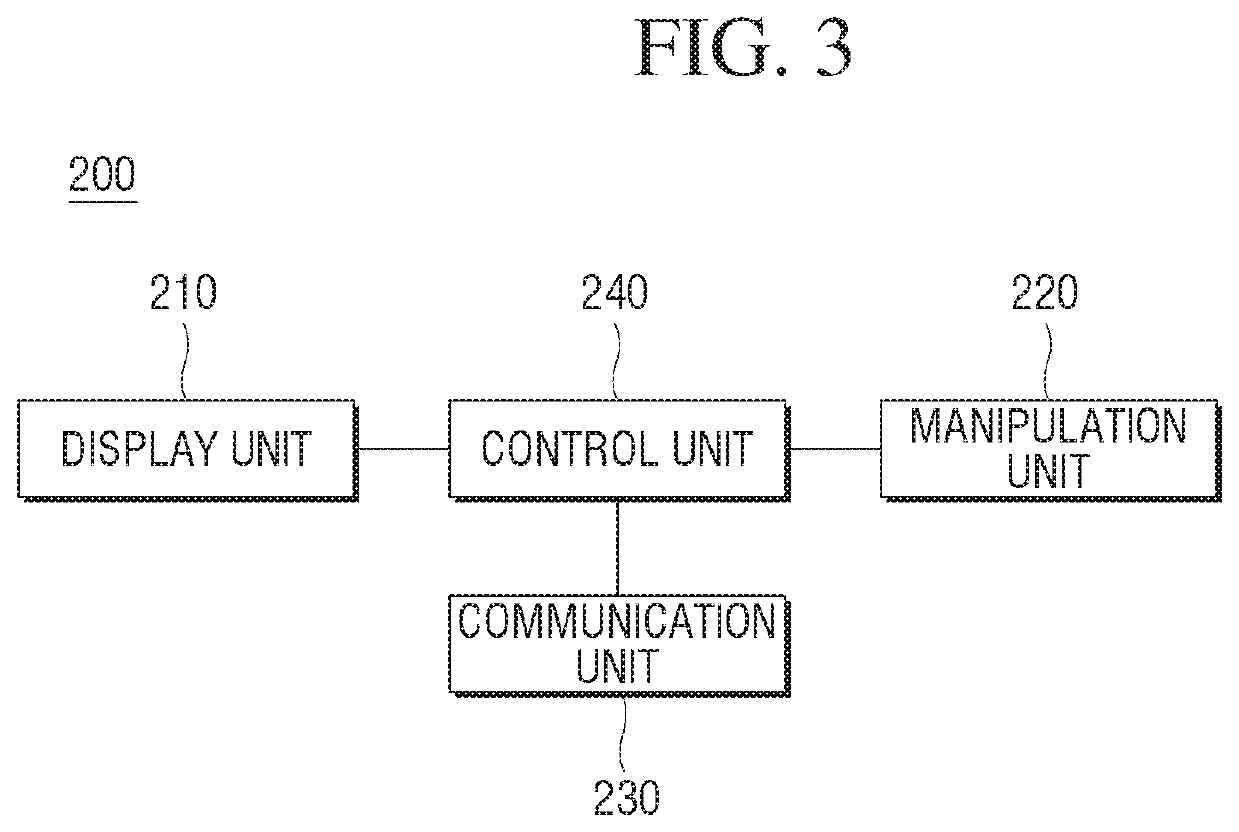

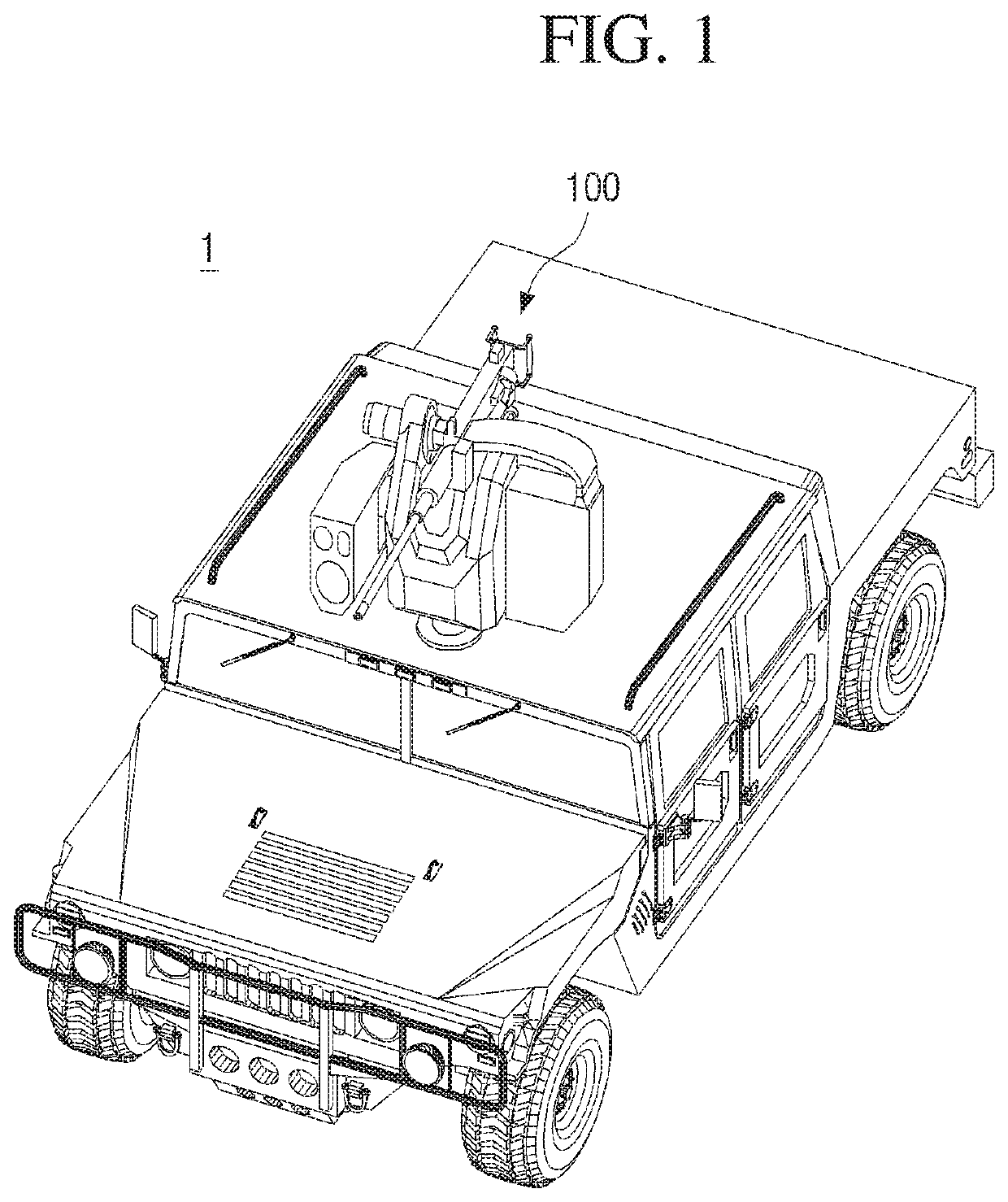

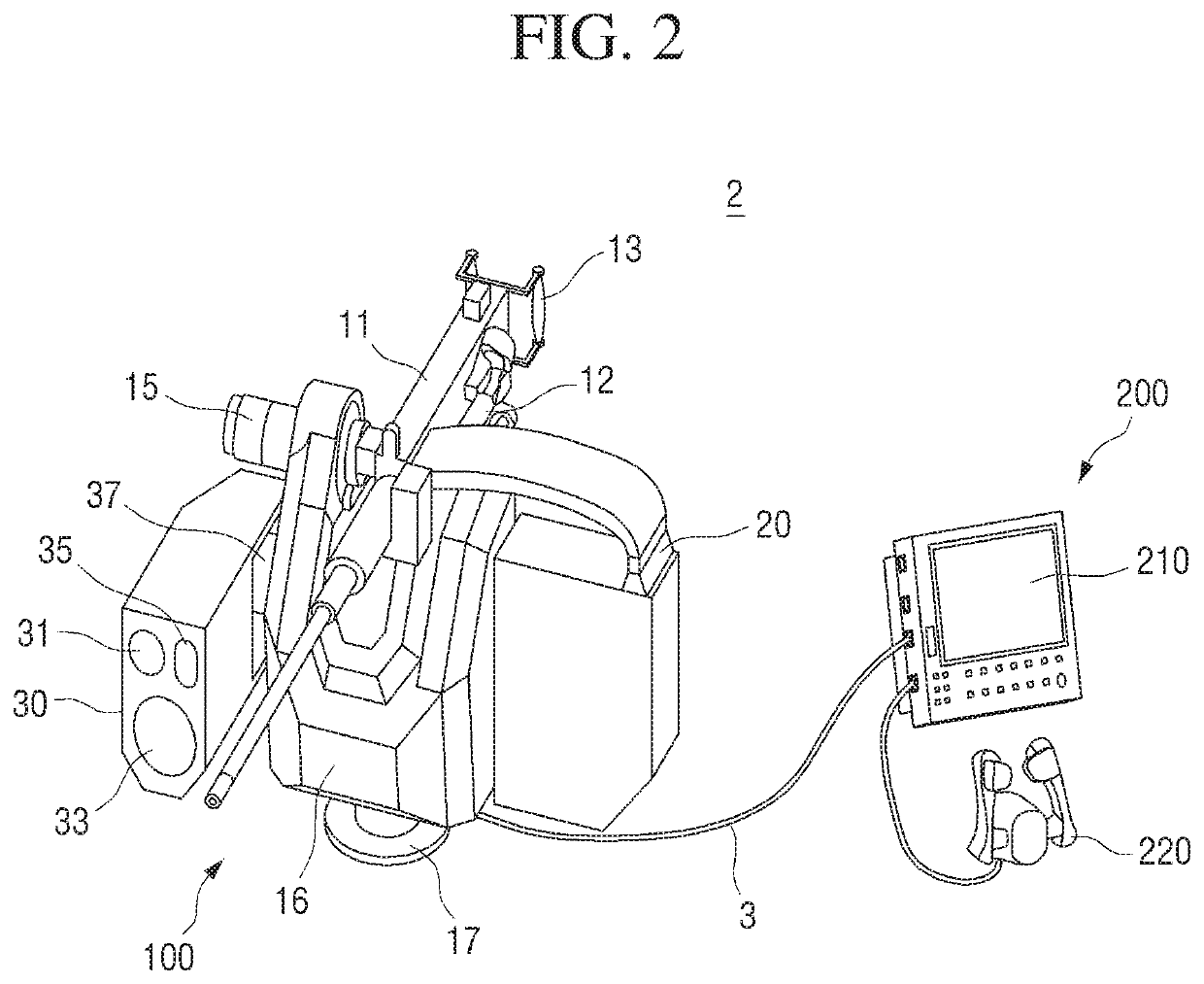

Apparatus and method for controlling striking apparatus and remote controlled weapon system

ActiveUS20200124381A1Effectively destroyEffectively neutralizeWeapon control systemsAiming meansRemote controlSimulation

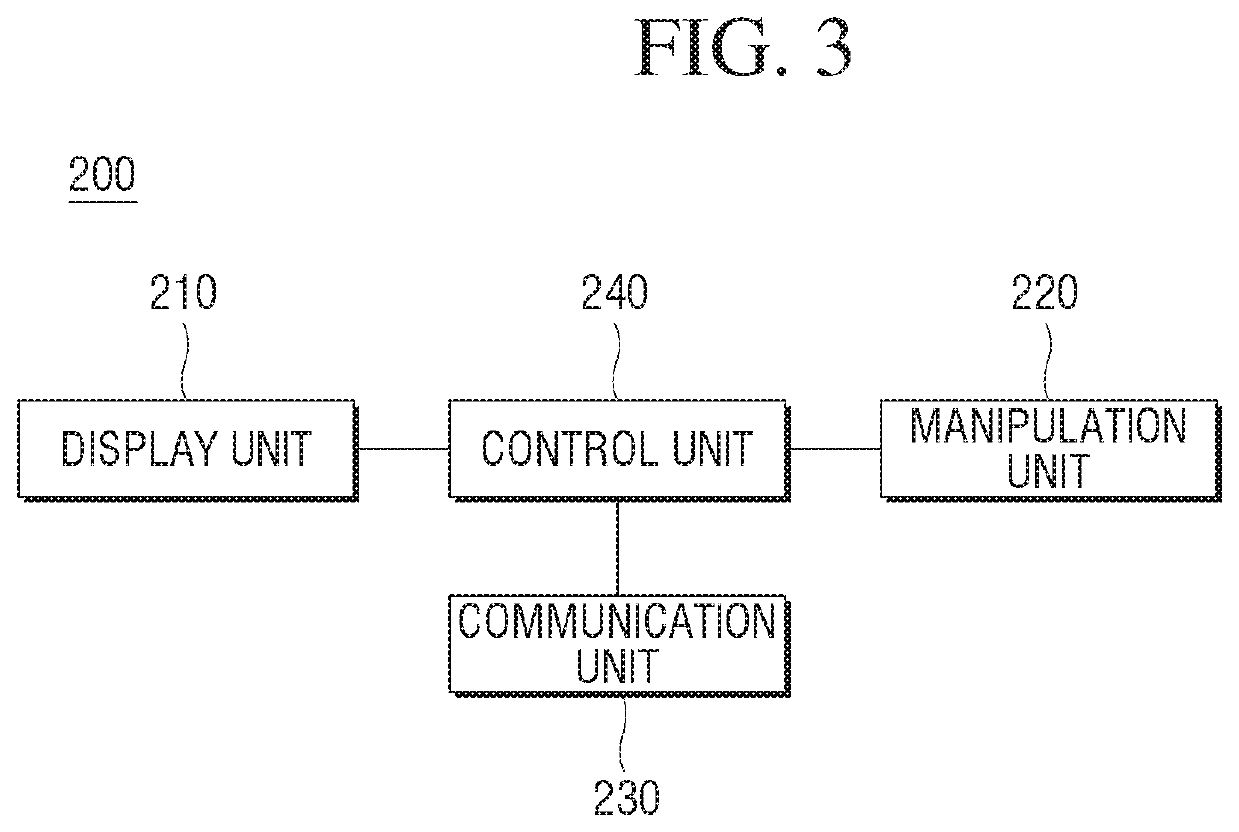

Provided is an apparatus for controlling a striking device. The apparatus for controlling the striking device equipped with a weapon to strike a target includes: a display unit which displays an image captured by a camera mounted on the striking device; a control unit which controls firing of the weapon; and a manipulation unit which transmits a fire signal to the control unit, wherein the control unit calculates the number of rounds of ammunition left in the striking device, calculates an accuracy rate which is a probability that the striking device will hit the target, and determines whether the target can be neutralized by considering the calculated number of rounds of ammunition left and the calculated accuracy rate for the target.

Owner:HANWHA AEROSPACE CO LTD

Method for disassembling touch screen

InactiveCN109176384AEfficient dismantlingCleaning using liquidsMetal-working hand toolsOrganic solventAdhesive

The invention provides a method for disassembling a touch screen. The touch screen is heated by a heating device, and the touch screen comprises a plurality of substrates bonded together by an adhesive; and when the adhesive in the touch screen is softened by heat, a metal wire is used for moving in gaps of the multiple substrates to separate the multiple substrates, and the separated substrates are placed in an organic solvent to remove the adhesive remaining on the surfaces of the substrates. The method for disassembling the touch screen cannot scratch a cover lens of a body, can efficientlydisassemble the cover lens and ITO glass engraved with an ITO line, and can recover the cover lens and ITO glass without the residual adhesive.

Owner:赣州市秋田微电子有限公司

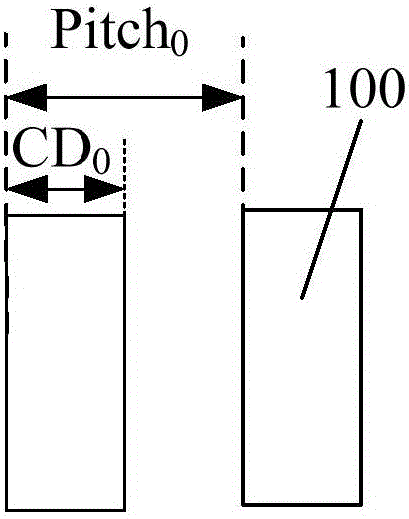

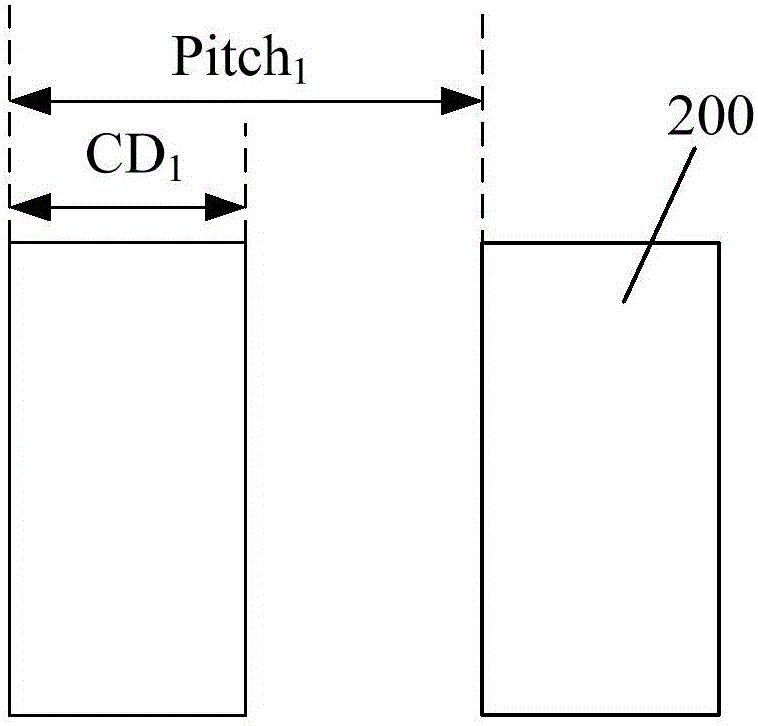

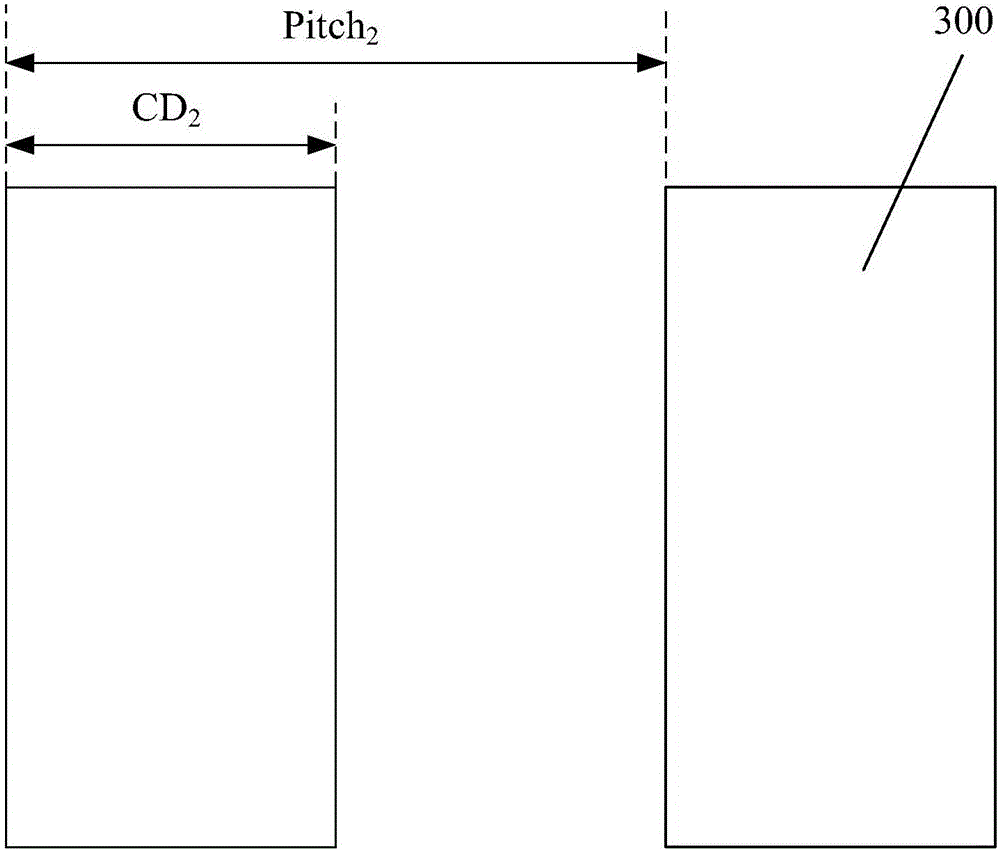

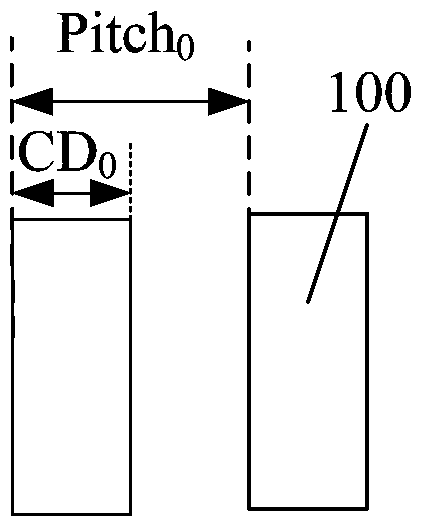

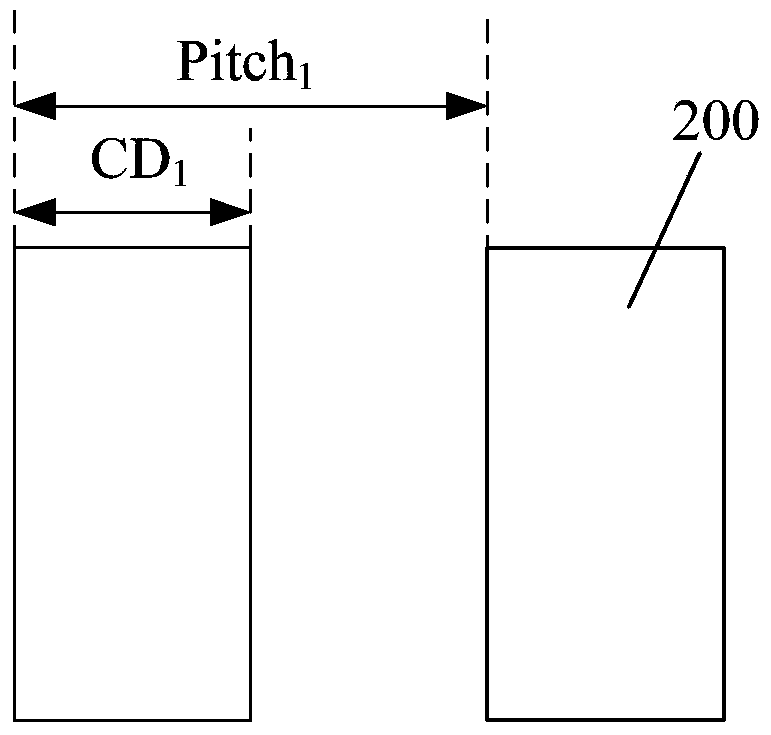

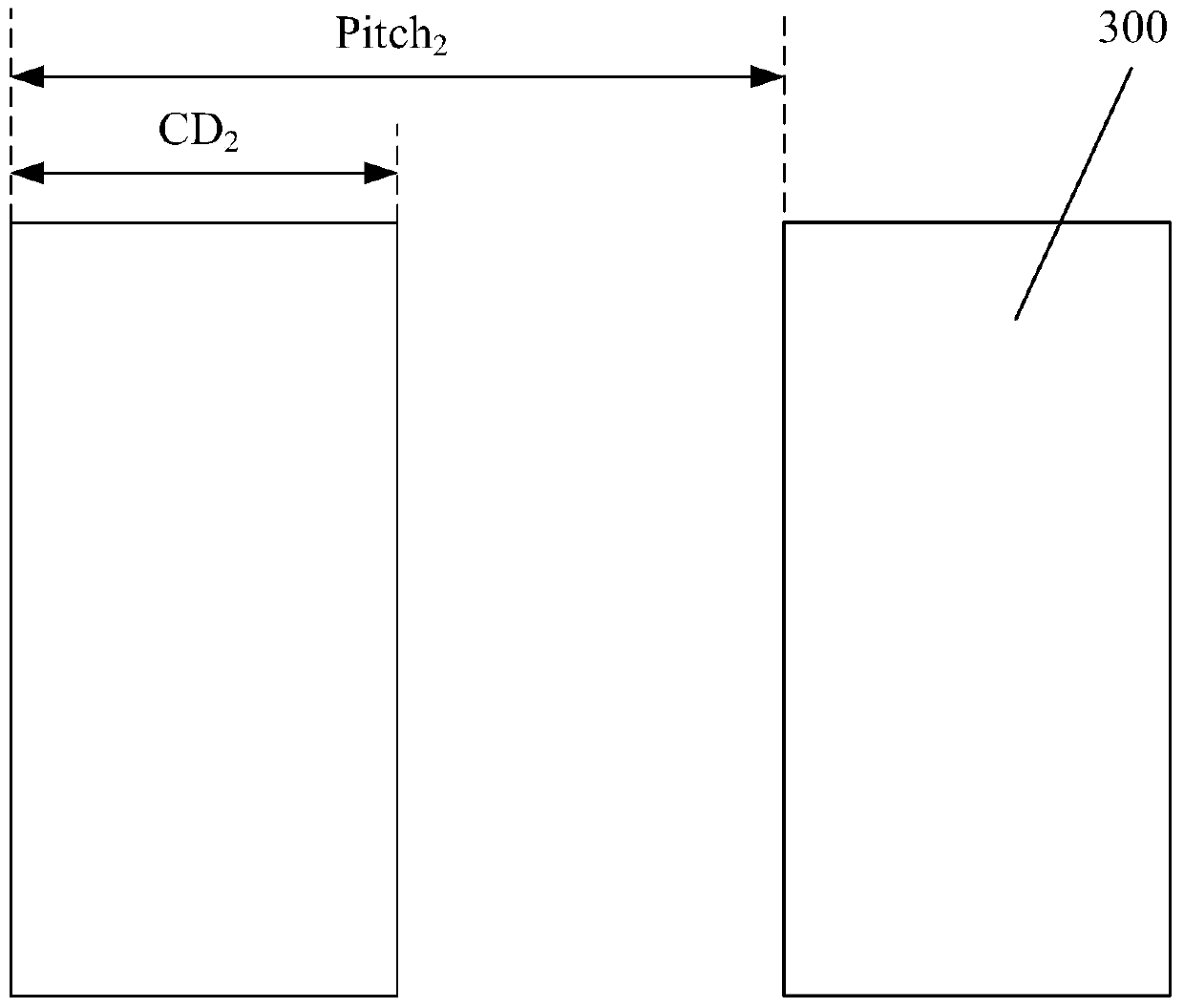

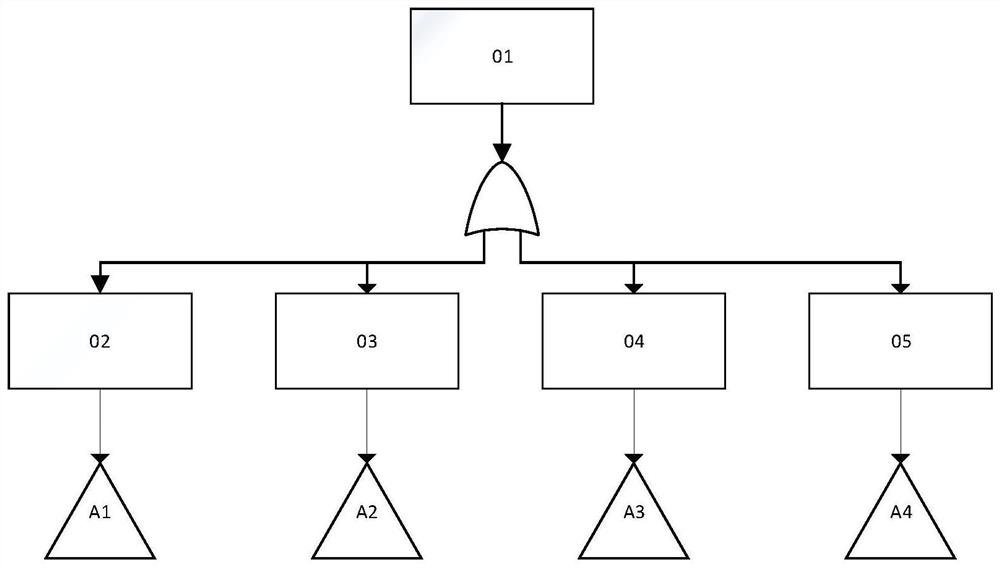

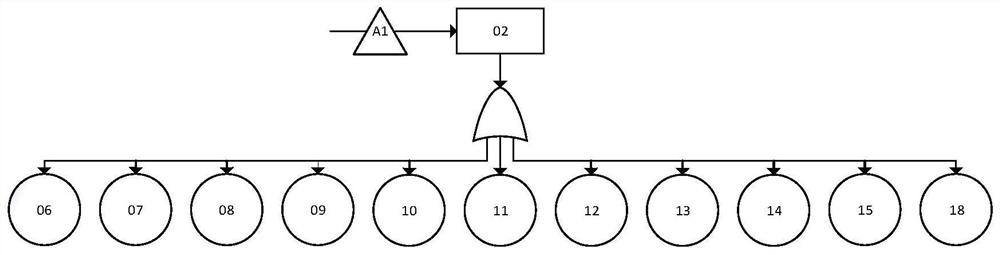

Method for forming test patterns

ActiveCN106707683ARich varietyRich quantityOriginals for photomechanical treatmentTheoretical computer scienceDesign pattern

A method for forming test patterns is provided; original test patterns in an original test pattern library are subjected to a series of transformation, and finally, a first test pattern and a second test pattern are obtained; the first test pattern and the second test pattern are added to the original test pattern library, and a new test pattern library is formed. In addition to comprising a plurality of original test patterns, the new test pattern library also comprises the first test pattern and the second test pattern, so the types and number of the test patterns in the new test pattern library are greatly enriched. Therefore, when original design patterns provided by customers are disassembled and detected subsequently, a best and most accurate first design pattern and second design pattern can be obtained, so as to help to form a higher-yield product subsequently.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Formation method of test pattern

ActiveCN106707683BRich varietyImprove yieldOriginals for photomechanical treatmentAlgorithmReliability engineering

A method for forming test patterns is provided; original test patterns in an original test pattern library are subjected to a series of transformation, and finally, a first test pattern and a second test pattern are obtained; the first test pattern and the second test pattern are added to the original test pattern library, and a new test pattern library is formed. In addition to comprising a plurality of original test patterns, the new test pattern library also comprises the first test pattern and the second test pattern, so the types and number of the test patterns in the new test pattern library are greatly enriched. Therefore, when original design patterns provided by customers are disassembled and detected subsequently, a best and most accurate first design pattern and second design pattern can be obtained, so as to help to form a higher-yield product subsequently.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Waste mobile phone disassembly fault intelligent classification processing method based on cloud computing

ActiveCN113194190AImprove efficiencyEfficient recyclingMathematical modelsSubstation equipmentEmbedded systemCloud computing

The invention discloses a waste mobile phone disassembly fault intelligent classification processing method based on cloud computing. The method comprises the following steps: carrying out the statistics of mobile phone faults, uploading the mobile phone faults to a cloud computing database, calculating the probability, completing the disassembly process, arranging a fault detection sequence according to the priority through the cloud computing database, and when a fault instruction is transmitted, downloading a corresponding fault solution instruction to a computer by the cloud computing database according to the arranged fault detection sequence according to the priority so as to operate machinery to solve the fault. According to the method, the fault probability is exported through the computer and the cloud computing database, the fault detection sequence is arranged according to the priority, and the fault detection efficiency is improved. The problem that manual disassembly is slow and low in efficiency is solved. Meanwhile, a cloud computing database is continuously enriched to cope with big data in the field of mobile phone disassembly, and solutions can be implemented more quickly when different faults occur.

Owner:QINGDAO UNIV OF SCI & TECH

A stainless steel metal recovery device

ActiveCN111250509BPrecise resectionEfficient dismantlingGrinding carriagesGrinding drivesCurlingStructural engineering

The invention relates to a metal recovery device, in particular to a stainless steel metal recovery device. The technical problem to be solved by the invention is to provide a stainless steel metal recovery device. A stainless steel metal recovery device, comprising a bottom connecting frame, an operation control panel, supporting feet, a top connecting frame, a middle top fixing frame, a handle dismantling mechanism, a bottom surface cutting mechanism, a curling removal mechanism and a roll separation mechanism; the bottom connection The middle and lower part of the left end of the frame is provided with a running control screen; the bottom left side of the bottom connection frame is connected with the support foot; the top right side of the bottom connection frame is connected with the top connection frame; the left side of the bottom connection frame is provided with a handle disassembly mechanism. The invention realizes the high-speed disassembly and separation of the handle and the stainless steel cylinder body, the precise cutting of the bottom panel of the wrinkled cylinder body, and finally the high-efficiency removal of the curling of the stainless steel rice cylinder, and cutting and compacting into plates to obtain the effect of recycling stainless steel plates.

Owner:佛山市敏瑞电器制品有限公司

Auxiliary dismantling device for differential dismantling

InactiveCN104493471BConvenient centralized disassemblyReduce secondary lossesProgramme-controlled manipulatorGripping headsHydraulic cylinderFuel tank

An auxiliary disassembly device for disassembly of differentials comprises a mechanical portion and a hydraulic control portion. The mechanical portion comprises a disassembly mechanism final-assembly frame, a lifting sleeve, a center shaft, a bolt disassembling spanner and a lifting mechanism mechanical claw. The hydraulic control portion comprises an oil tank, a hydraulic pump, a hydraulic loop pipeline, a control valve set and a hydraulic cylinder. Damage-free disassembly of the differentials is realized by combined motion of the mechanical portion and the hydraulic portion, the center shaft is used for positioning and limiting, the bolt disassembling spanner is used for disassembly, and the lifting mechanism mechanical claw is used for grabbing a differential left shell to complete separation. The auxiliary disassembly device for disassembly of the differentials has the advantages that the problems of high labor intensity, low efficiency, large damage and primitiveness of differential disassembly means in manufacturing are solved, disassembly tools are integrated, and high efficiency, excellent quality, energy saving, material saving and environment friendliness are achieved.

Owner:GUANGXI UNIV

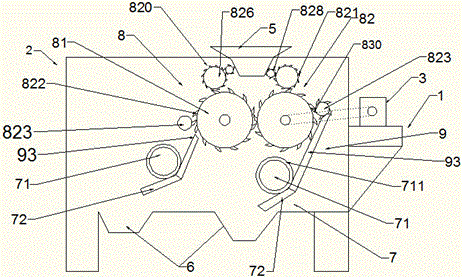

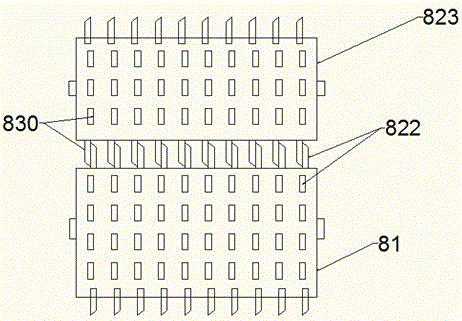

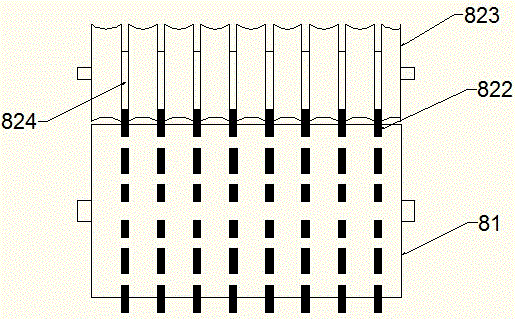

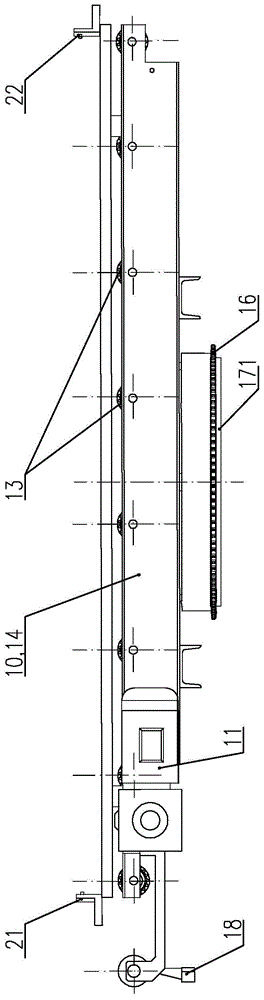

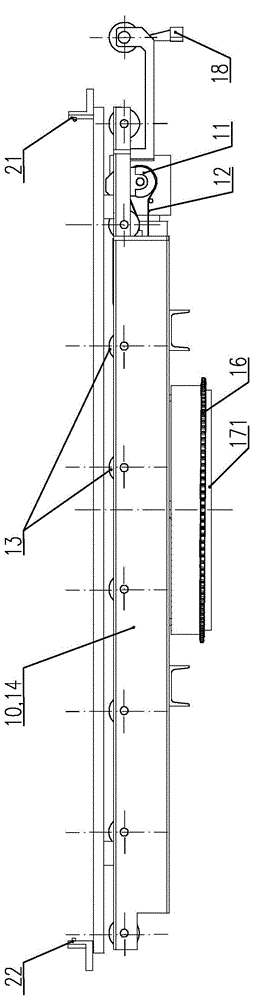

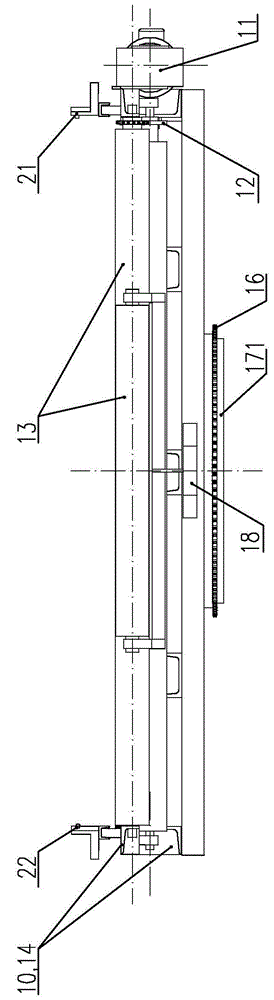

Wire tidying cutting shafts of a waste wire automatic disassembling device

ActiveCN105931763ASimple structureAvoid pollutionBasic electric elementsElectronic waste recyclingEngineeringMechanical engineering

The invention provides wire tidying cutting shafts of a waste wire automatic disassembling device. Each wire tidying cutting shaft is arranged behind a wire blocking devices; and the wire tidying cutting shafts and wire tidying rollers are fixedly arranged in a machine body in parallel respectively. The surface of each wire tidying cutting shaft is provided with a cutter structure in close fit with wire tidying hook blades. The surface of each wire tidying cutting shaft is provided with hook blade bulges, which are in close fit with the wire tidying hook blades to form the cutter structure. The wire tidying cutting shaft is of a roller structure and is connected with a speed regulation machine. The circumference surface of each wire tidying cutting shaft is provided with the hook blade bulges, which are in close fit with the wire tidying hook blades to form the cutter structure. The surface of each wire tidying cutting shaft is provided with hook blade grooves for allowing the wire tidying hook blades to pass respectively. The wire tidying hook blades and the hook blade grooves are cooperated closely to form the cutter structure. The wire tidying cutting shaft is of the roller structure and is connected with a speed regulation machine; and the hook blade grooves for allowing the wire tidying hook blades to pass are annularly arranged in the circumference surface of the roller wire tidying cutting shaft, and the wire tidying hook blades and the annular hook blade grooves in the circumference surface of the roller wire tidying cutting shaft are in close fit to form the cutter structure.

Owner:江苏祥云塑料科技有限公司

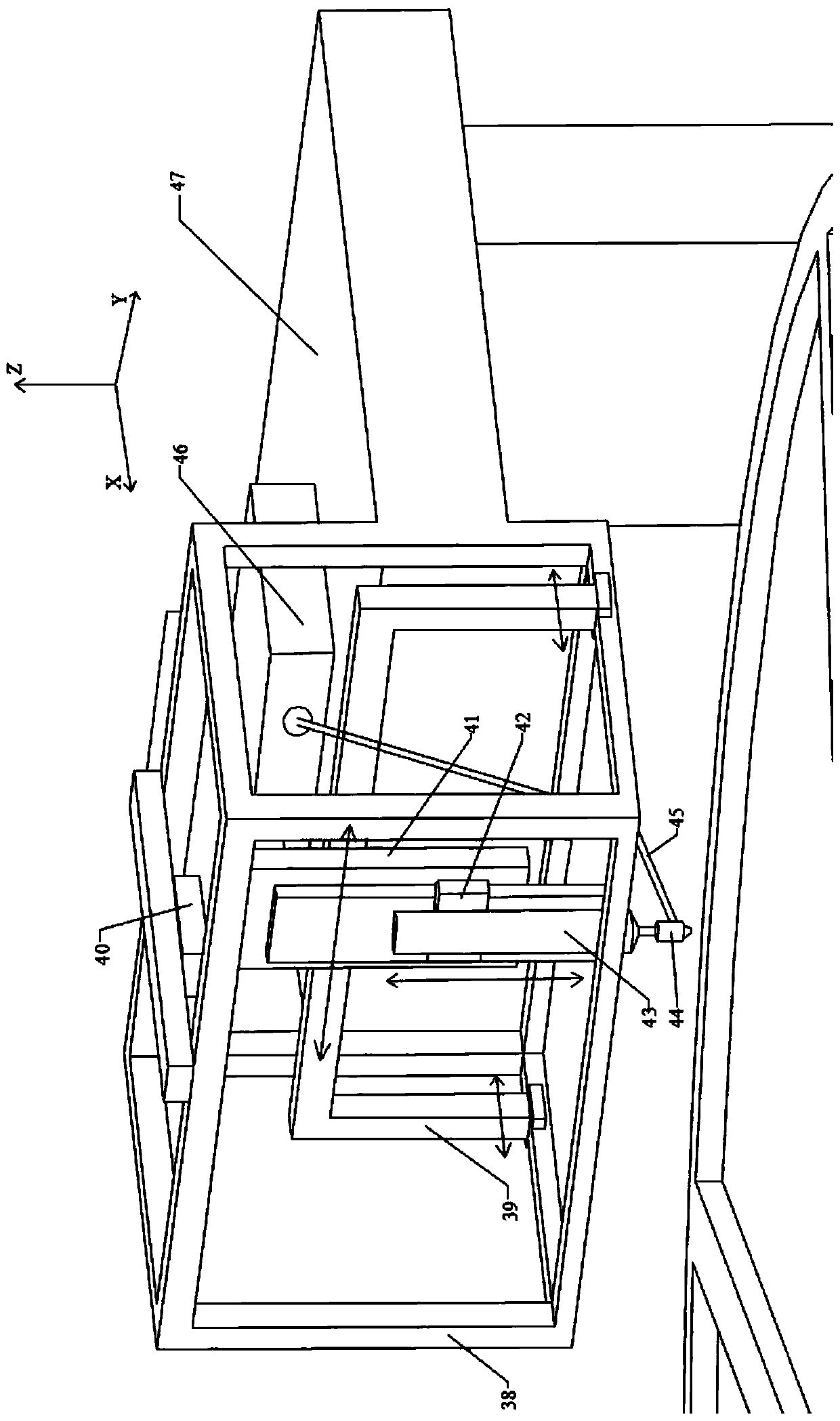

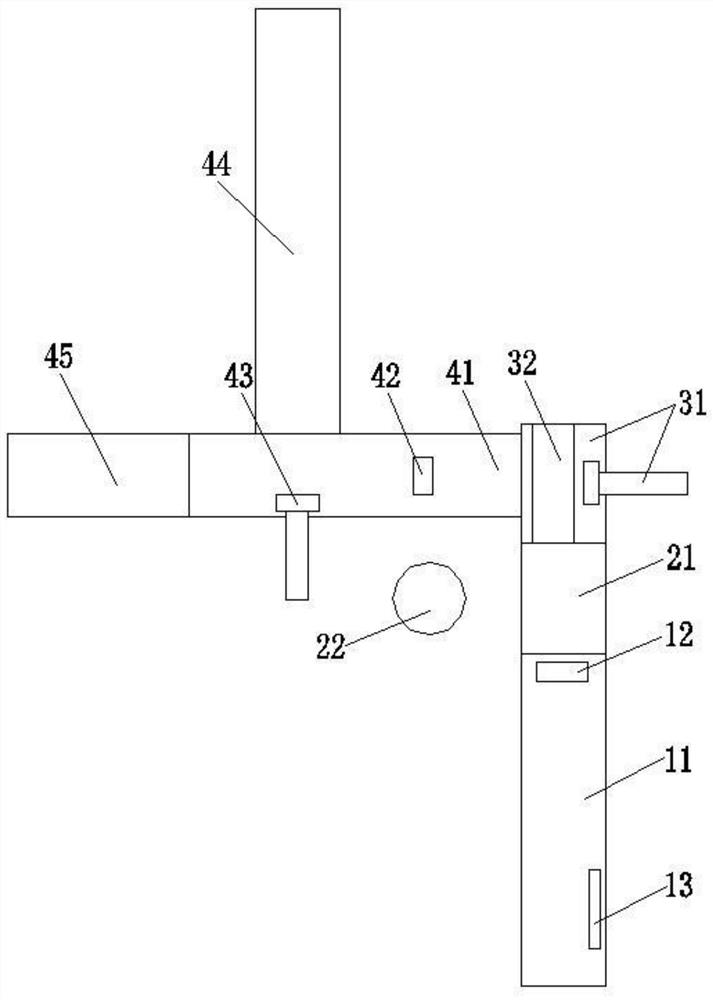

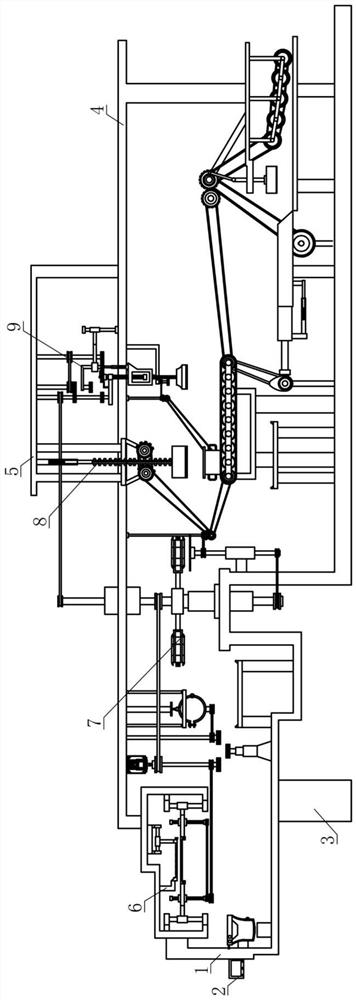

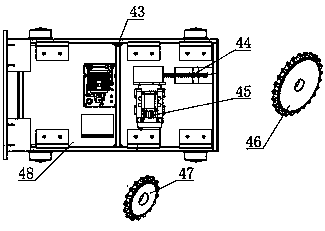

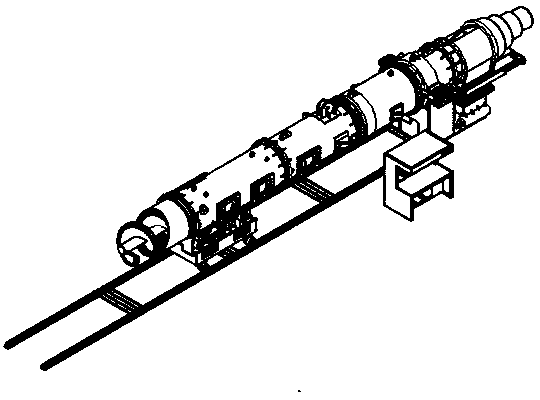

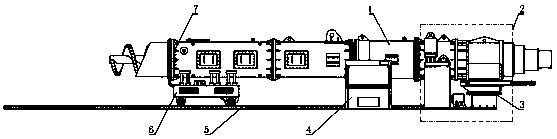

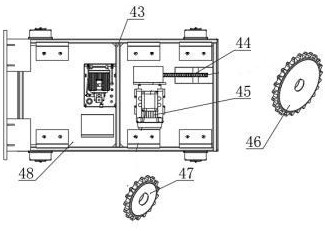

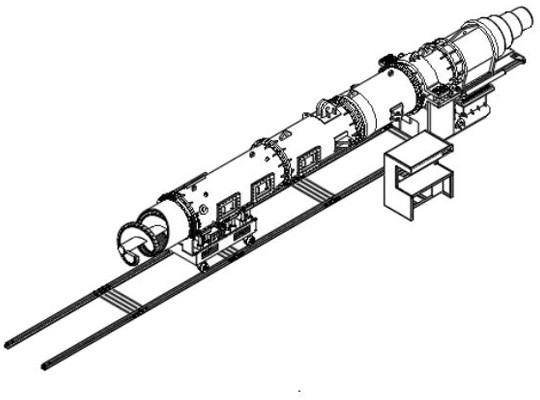

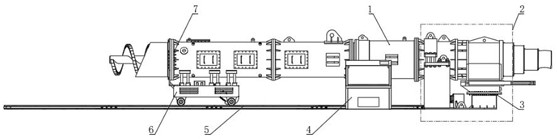

Disassembling device for spiral conveyor of shield tunneling machine

The invention belongs to the technical field of engineering equipment, and provides a disassembling device for a spiral conveyor of a shield tunneling machine. The disassembling device is provided with a supporting mechanism used for supporting the spiral conveyor of the shield tunneling machine, wherein a supporting seat is fixed on a bottom plate of the supporting mechanism; an upper supportingcover plate is arranged right above the supporting seat correspondingly; the upper supporting cover plate and the supporting seat jointly form a supporting component used for supporting the spiral conveyor of the shield tunneling machine; an adjusting oil cylinder fixed to the bottom plate is arranged on the rear side of the supporting component, and a lifting plate is arranged at the top of the adjusting oil cylinder; the lifting plate is in threaded connection with the tail part of the spiral conveyor; the front end of the supporting mechanism is connected with a guide rail; a moving trolleycapable of moving back and forth on the guide rail is arranged on the guide rail; and a cylinder taking ring and a plurality of groups of lifting oil cylinders are fixed on the moving trolley. According to the disassembling device, the mechanization degree of disassembling of the spiral conveyor of the shield tunneling machine is improved, labor intensity and labor cost are reduced, and great convenience is provided for a follow-up renovation or remanufacturing process.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A shield screw conveyor dismantling device

ActiveCN111056242BDisassembly safetyEfficient dismantlingPackagingStructural engineeringScrew conveyor

The invention belongs to the technical field of engineering equipment, and provides a dismantling device for a shield screw conveyor. The proposed dismantling device for shield screw conveyor has a support mechanism for supporting the shield screw conveyor; a support seat is fixed on the bottom plate of the support mechanism; a support upper cover plate is provided directly above the support seat; the support upper cover The plate and the support seat together form a support part used to support the shield screw conveyor; the rear side of the support part has an adjustment oil cylinder fixed on the bottom plate, and a lift plate is arranged on the top of the adjustment oil cylinder; the lift plate is screwed on the The tail of the screw conveyor; the front end of the support mechanism is connected with a guide rail; the upper part of the guide rail is provided with a mobile trolley that can move forward and backward on the guide rail; The invention improves the degree of mechanization of the dismantling of the shield screw conveyor, reduces labor intensity and labor cost, and provides great convenience for the subsequent repair or remanufacturing process.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

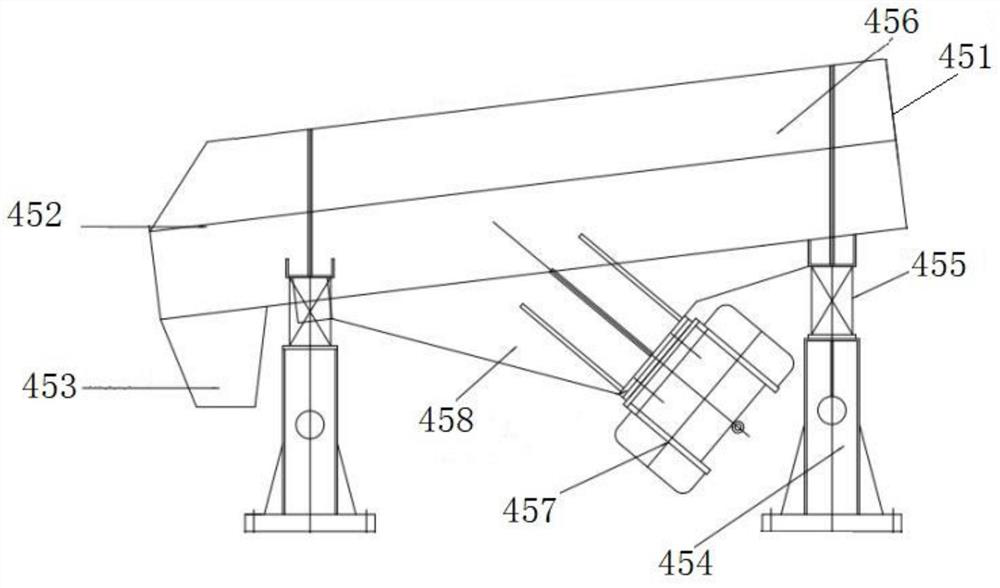

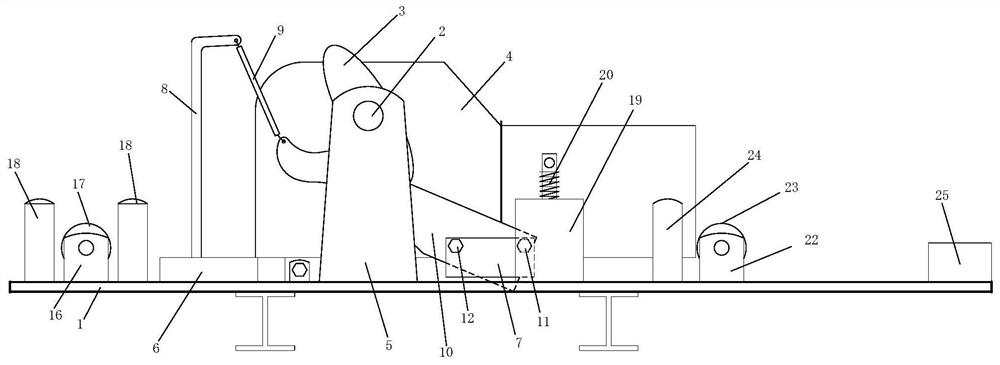

Flat tail rope dismantling machine

ActiveCN110947879BEfficient dismantlingLess manpowerSolid waste disposalElectric machineryDrive motor

The invention discloses a flat tail rope dismantling machine, which comprises a chassis. A cutting structure is arranged in the middle of the chassis. The cutting structure includes a driving part and a cutter part. The driving part includes a driving bracket. A cam is arranged in the center, and a drive motor is connected to one side of the rotating shaft. The cutter part comprises a spring rod seat and a cutter seat, a spring rod is arranged on the spring rod seat, and a spring is connected to the top of the spring rod. The tilting hinge on the cutter seat is connected with a cutter, and the front end of the cutter is connected with the lower end of the spring. The rotation of the cam can intermittently press the top of the cutter to move the cutter down. The invention cuts off the braided wire of the flat tail rope from the middle through the cutting structure, and then separates the main core wire from the braided wire by using the rope dividing structure through the pulling of the rope receiving drum. The dismantling machine can efficiently disassemble the flat tail rope, consumes less manpower, and the dismantled main core wire can be reused, thereby achieving the purpose of repairing old and waste, and saving costs.

Owner:临沂矿业集团菏泽煤电有限公司

Motor shell accurate cutting device

PendingCN108406285AEfficient dismantlingQuick disassemblyTurning machinesMetal working apparatusEngineeringMechanical engineering

The invention provides a motor shell accurate cutting device, and belongs to the field of disassembling jigs. The motor shell accurate cutting device comprises a rotating clamping head and an abuttinghead which are arranged oppositely, a motor is arranged between the rotating clamping head and the abutting head, and the rotating clamping head and the abutting head can rotate synchronously. The opening and closing of the rotating clamping head can be realized by a first air cylinder, and the clamping and releasing of the motor are completed. A turning tool is vertically arranged in the axial direction of the motor, the contraction and retraction of the turning tool is realized by a second air cylinder, and fine-tuning and precise positioning are realized through a micro-metering head. Themotor shell accurate cutting device can accurately cut a shell of the motor to avoid damage to the internal parts and has high precision.

Owner:天津爱普勒斯电子有限公司

Multi-layer roller table steering machine and its tree-shaped roller table conveying system for dismantling industry

ActiveCN103523448BFlexible disassemblyFlexible distributionPackagingMechanical conveyorsSprocketEngineering

Disclosed are a multi-layered roller table steering device and a tree-form roller table conveyance system for the dismantling industry thereof, wherein the multi-layered roller table steering device comprises a base (30) and roller table sections (10), the base (30) comprises n layers of frame, an edge part of each layer of frame being provided with a steering electric motor (38) having a driving sprocket (33), and a limiter (32). The multi-layered roller table steering device further comprises n layers of roller table section (10), wherein a driven sprocket (16) and a steering bearing are connected to a lower face of the middle part of each layer of roller table section (10), which is rotatably fitted to the upper face of the middle of each layer of frame via the steering bearing, an edge part of each layer of roller table section (10) is provided with a trigger block (18) corresponding to the limiter (32) on each layer of frame, and the driven sprocket (16) thereof is connected to the driving sprocket (33) on each layer of frame via a steering chain (19); and the upper part of each layer of roller table section (10) is provided with a material sensor for detecting material. Under the premise of reducing or saving space occupied by dismantling, the present application can construct conveying roller tables the length of which can be expanded several times over and a tree-form roller table conveyance system in which the number of intersections is increased.

Owner:WUHAN GEM URBAN MINE EQUIP +3

One-stop dismantling equipment for small cars

ActiveCN108749960BSolve the problem of low disassembly efficiencyEfficient disassemblyVehicle dissasembly recoverySolid waste disposalMagnetic separatorElectric machinery

The invention discloses a one-stop type disassembling process for a small-sized automobile. The one-stop type disassembling process for the small-sized automobile comprises slide rails; the number ofthe slide rails is two; and slide grooves are formed in the tops of the slide rails. According to the one-stop type disassembling process for the small-sized automobile, through coordination of a cutting frame, a cutting device, an adjusting frame, rolling wheel carriers, rolling wheels, a motor, a rotating shaft, a rotating disc, a first electric telescopic rod, a first fixing disc, a treatment box, a compression box, a supporting frame, a second motor, a threaded rod, a threaded sleeve, first hydraulic rods, second fixing discs, a second hydraulic rod, a first extrusion plate, a third hydraulic rod, a second extrusion plate, driving mechanisms, crushing rollers, discharging inclined plates, a screening box, a magnetic separator, a fan, an article storage box and a material fetching device, the problem that the disassembling efficiency of the traditional one-stop type disassembling process for the small-sized automobile is low is solved; and the one-stop type disassembling process forthe small-sized automobile has the advantages that the disassembling is efficient, time and labor are both saved during disassembling, the disassembling effect is good, and the disassembling efficiency is greatly enhanced.

Owner:广东拓展资源综合利用开发有限公司

Apparatus and method for controlling striking apparatus and remote controlled weapon system

ActiveUS11118866B2Effectively destroyEffectively neutralizeWeapon control systemsAiming meansRemote controlSimulation

Provided is an apparatus for controlling a striking device. The apparatus for controlling the striking device equipped with a weapon to strike a target includes: a display unit which displays an image captured by a camera mounted on the striking device; a control unit which controls firing of the weapon; and a manipulation unit which transmits a fire signal to the control unit, wherein the control unit calculates the number of rounds of ammunition left in the striking device, calculates an accuracy rate which is a probability that the striking device will hit the target, and determines whether the target can be neutralized by considering the calculated number of rounds of ammunition left and the calculated accuracy rate for the target.

Owner:HANWHA AEROSPACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com