Wire tidying cutting shafts of a waste wire automatic disassembling device

A technology of waste wires and cutting shafts, which is applied to the recycling of circuits, electrical components, and electronic waste. It can solve the problems of low efficiency of stuck wires and wire management, and achieve the effects of increasing equipment automation, improving work efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

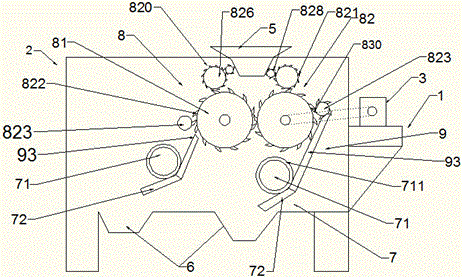

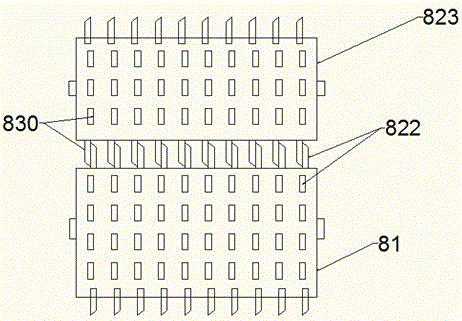

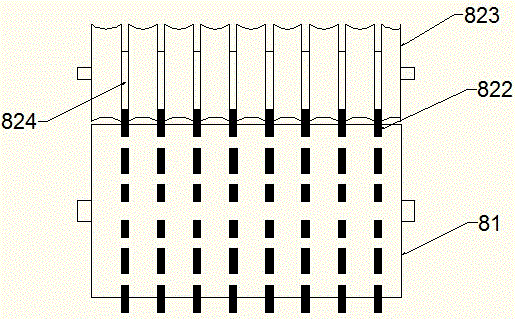

[0017] combine figure 1 and figure 2 , the company has developed an automatic dismantling equipment for waste and old wires, including a frame 1, a body 2, a motor, and a speed controller 3; the motor and the speed controller 3 are linked and installed on the frame 1; 2 The upper part is provided with a feed port 5, and the lower part of the body 2 is provided with a discharge port 6; a wire cutting mechanism 7 is provided in the body 2; it is characterized in that: it also includes a wire management mechanism 8 and a wire feeding mechanism 9; The wire management mechanism 8 includes at least one wire management roller 81, and a hook cutting device 82 cooperating with the wire management roller 81; the speed governor 3 links the wire management roller 81; One side of the wire drum 81 is assembled parallel to the wire drum 81, and at the connection portion of the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com