Method and equipment for recovering main reinforcing bar in concrete beam

A technology of concrete beams and main steel bars, which is applied to the removal of solid waste and grain processing, etc. It can solve the problems of high strength, no effective treatment of internal steel bars, and messy steel bars, etc., so as to improve the recycling rate and facilitate daily maintenance The effect of reliable and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0055]The purpose of the equipment for recovering the main steel bars in concrete beams of the present invention is to crush the concrete beam 1, and then take out the steel bars therein, especially cut and clean the thin stirrups, keep the thick main steel bars, and The main steel bar is cut off as needed, which is convenient for recycling and reuse, and improves the recycling rate.

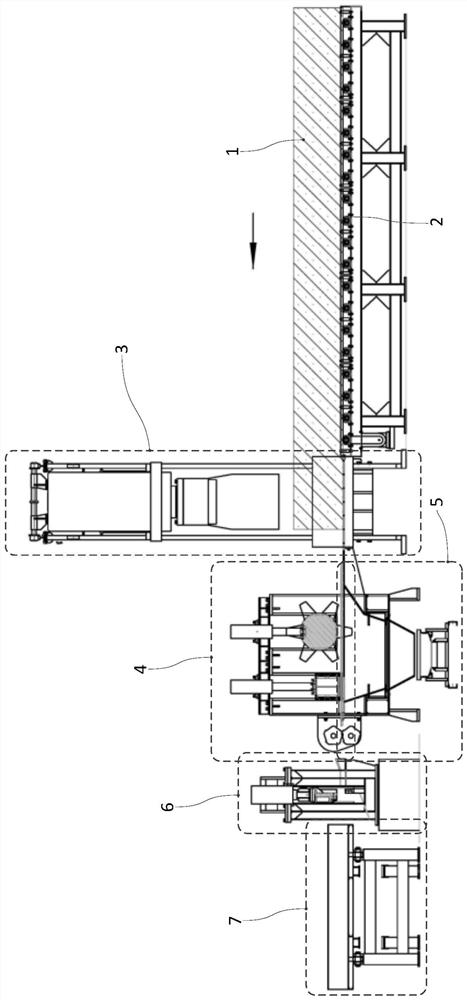

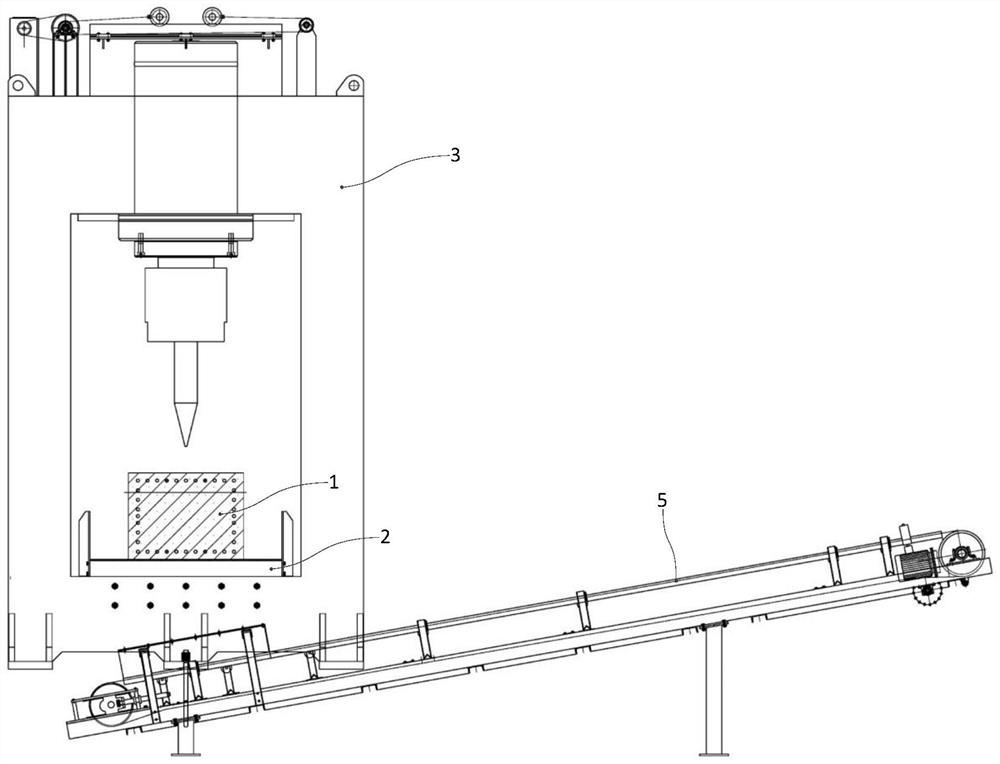

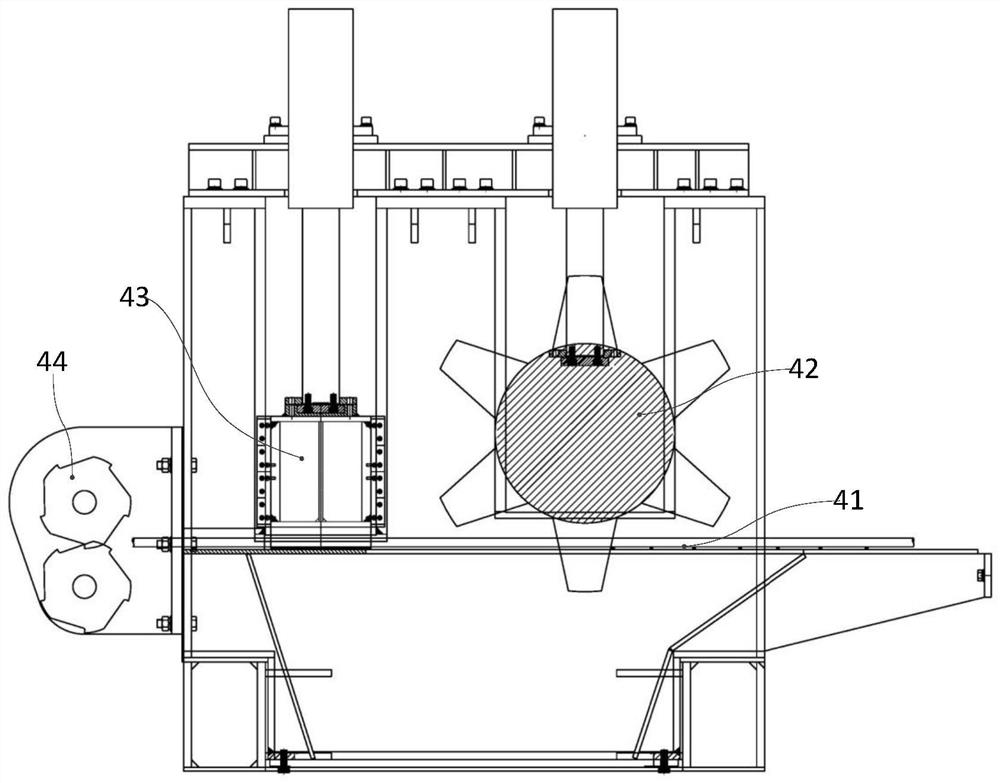

[0056] like figure 1 Shown, be the overall structure schematic diagram of the equipment that the present invention reclaims the main steel bar in the concrete girder, comprise feeding table 2, crusher 3, rolling crusher 4, waste material output machine 5, main steel bar shearing machine 6, main Rebar collector7.

[0057] The conveying table 2 is equipped with a reducer and a conveying roller driven by a sprocket chain, which can convey t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com