Manufacturing method of easily recoverable electroplated diamond grinding wheel

A technology of electroplating diamonds and manufacturing methods, applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems of recycling troubles, loss of cutting ability, expensive diamond abrasive grains, etc., and achieve easy recycling and efficient dismantling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

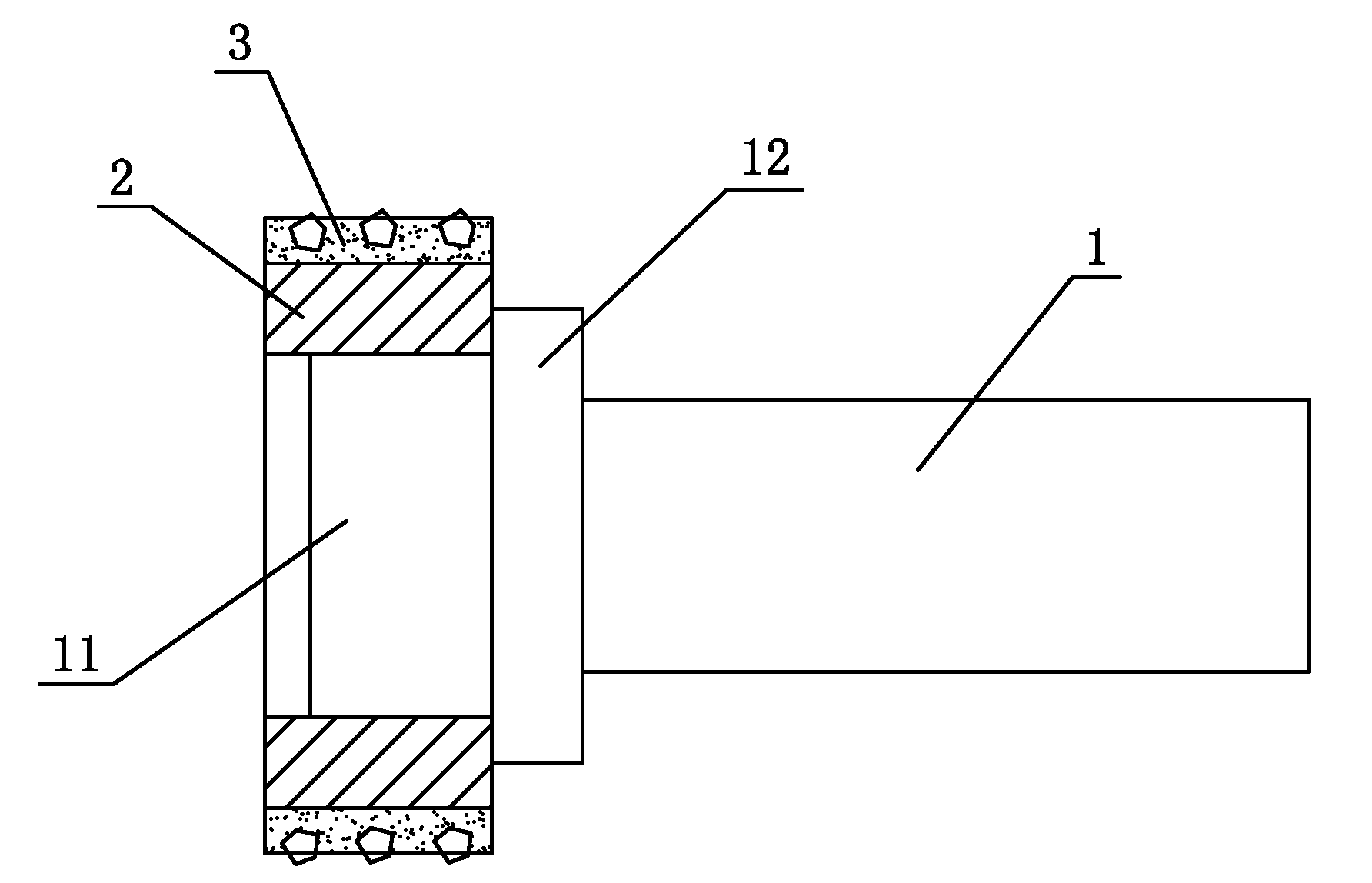

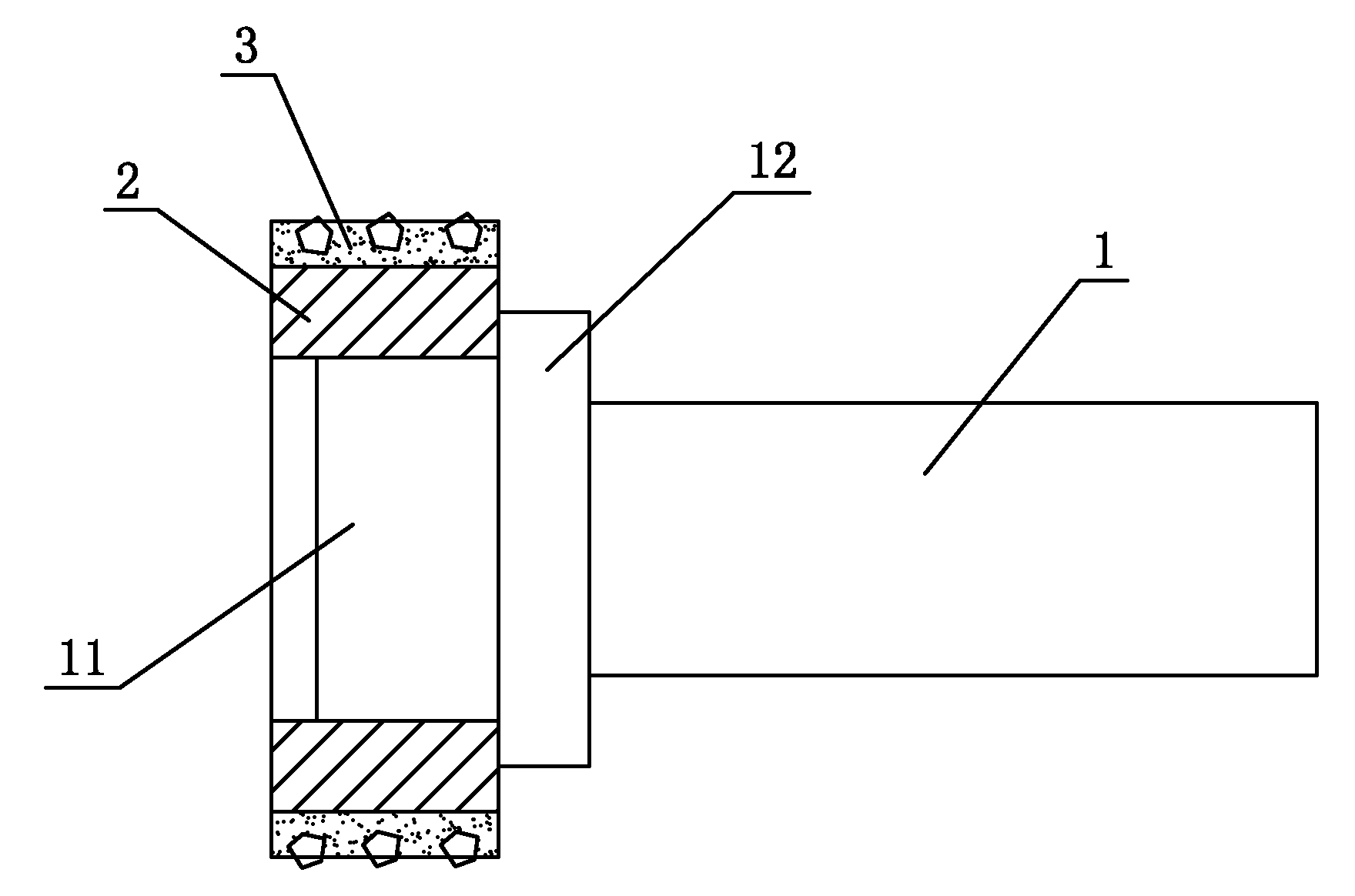

[0016] Embodiment one: as shown in the figure, a kind of manufacturing method of electroplated diamond grinding wheel that is easy to recover comprises the following steps:

[0017] (1) Take the base body 1 made of 45# steel and the auxiliary base body 2 with an outer diameter of 20mm, process a cylindrical connection part 11 with a diameter of 16.01mm on the base body 1, and control the length ratio of the connection part 11 to the auxiliary The length of the base body 2 is 0.5mm smaller, and the stepped shaft 12 is processed at the transition between the base body 1 and the connecting part 11, and the outer diameter of the stepped shaft 12 is smaller than the outer diameter of the auxiliary base body 2 and larger than the diameter of the connecting part 11. In the auxiliary base body 2 The inner hole with a diameter of 16mm is processed on the top;

[0018] (2) Heat the auxiliary base 2 at a temperature of 80° C. for 10 minutes to expand the auxiliary base 2 under heat, and ...

Embodiment 2

[0021] Embodiment two: a kind of manufacturing method of the electroplated diamond grinding wheel that is easy to recycle comprises the following steps:

[0022] (1) Take the base body 1 made of 45# steel and the auxiliary base body 2 with an outer diameter of 100 mm, and process a cylindrical connection part 11 with a diameter of 93.38 mm on the base body 1, and control the length ratio of the connection part 11 to the auxiliary The length of the base body 2 is 1 mm smaller, and a stepped shaft 12 is processed at the transition between the base body 1 and the connecting portion 11, and the outer diameter of the stepped shaft 12 is smaller than the outer diameter of the auxiliary base body 2 and larger than the diameter of the connecting portion 11. On the auxiliary base body 2 Machining an inner hole with a diameter of 92mm;

[0023] (2) Heat the auxiliary base 2 at a temperature of 150° C. for 30 minutes to expand the auxiliary base 2 under heat, and then install the expande...

Embodiment 3

[0026] Embodiment three: a kind of manufacturing method of the electroplated diamond grinding wheel that is easy to recover comprises the following steps:

[0027] (1) Take the base body 1 made of alloy steel and the auxiliary base body 2 with an outer diameter of 60 mm, and process a cylindrical connection part 11 with a diameter of 52.1 mm on the base body 1, and control the length ratio of the connection part 11 to the auxiliary base body The length of 2 is 1.5mm smaller, and the stepped shaft 12 is processed at the transition between the base body 1 and the connecting part 11, and the outer diameter of the stepped shaft 12 is smaller than the outer diameter of the auxiliary base body 2 and larger than the diameter of the connecting part 11. On the auxiliary base body 2 Machining an inner hole with a diameter of 52mm;

[0028] (2) Heat the auxiliary base 2 at a temperature of 280° C. for 50 minutes to expand the auxiliary base 2 under heat, and then install the expanded aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com