Automatic disassembly equipment appliable to flow process and used for waste mobile phones

An assembly line and mobile phone technology, applied in the field of automatic dismantling equipment for used mobile phones, can solve the problems of low recycling value, consuming a lot of manpower and material resources, and low dismantling efficiency, so as to improve the accuracy, success and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

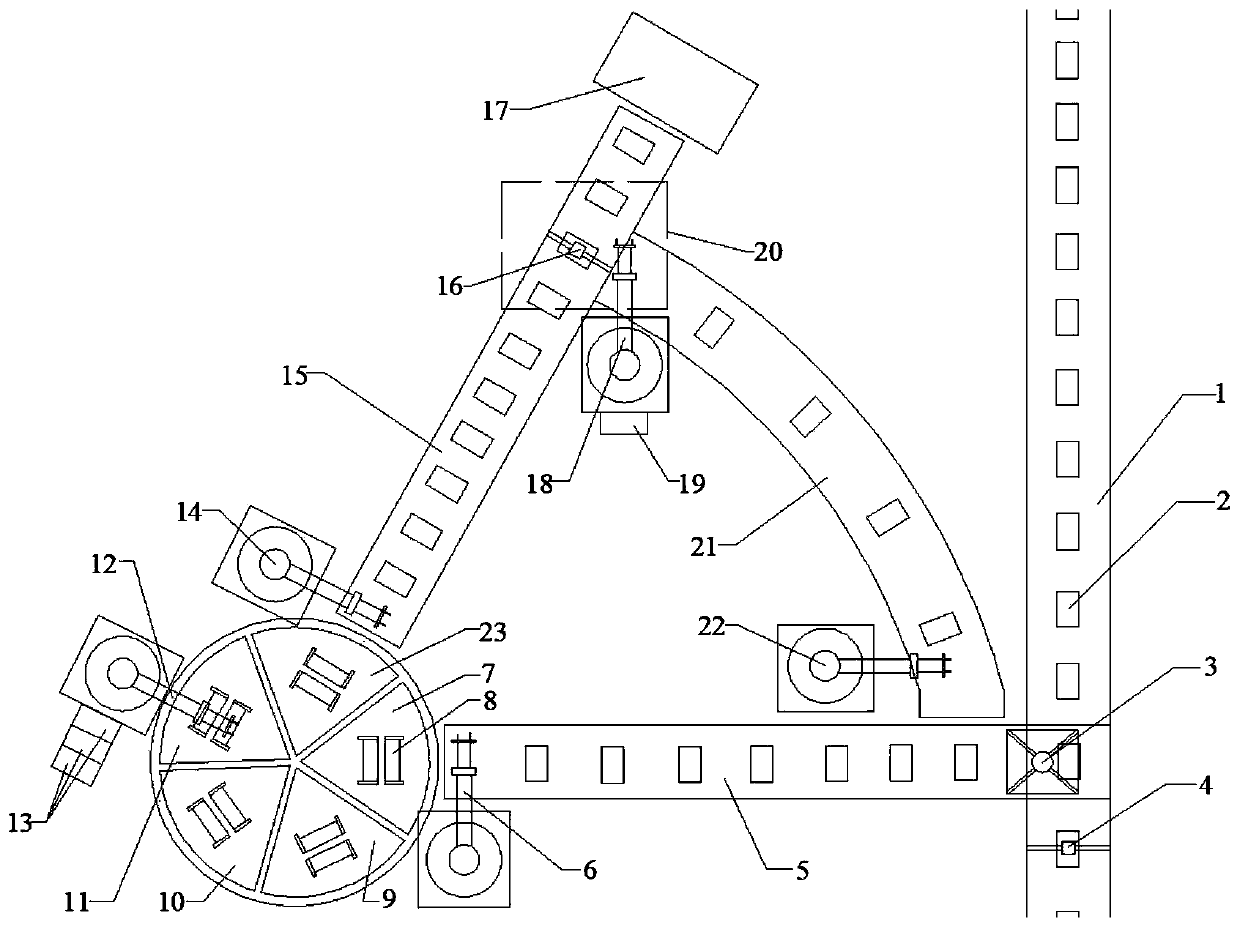

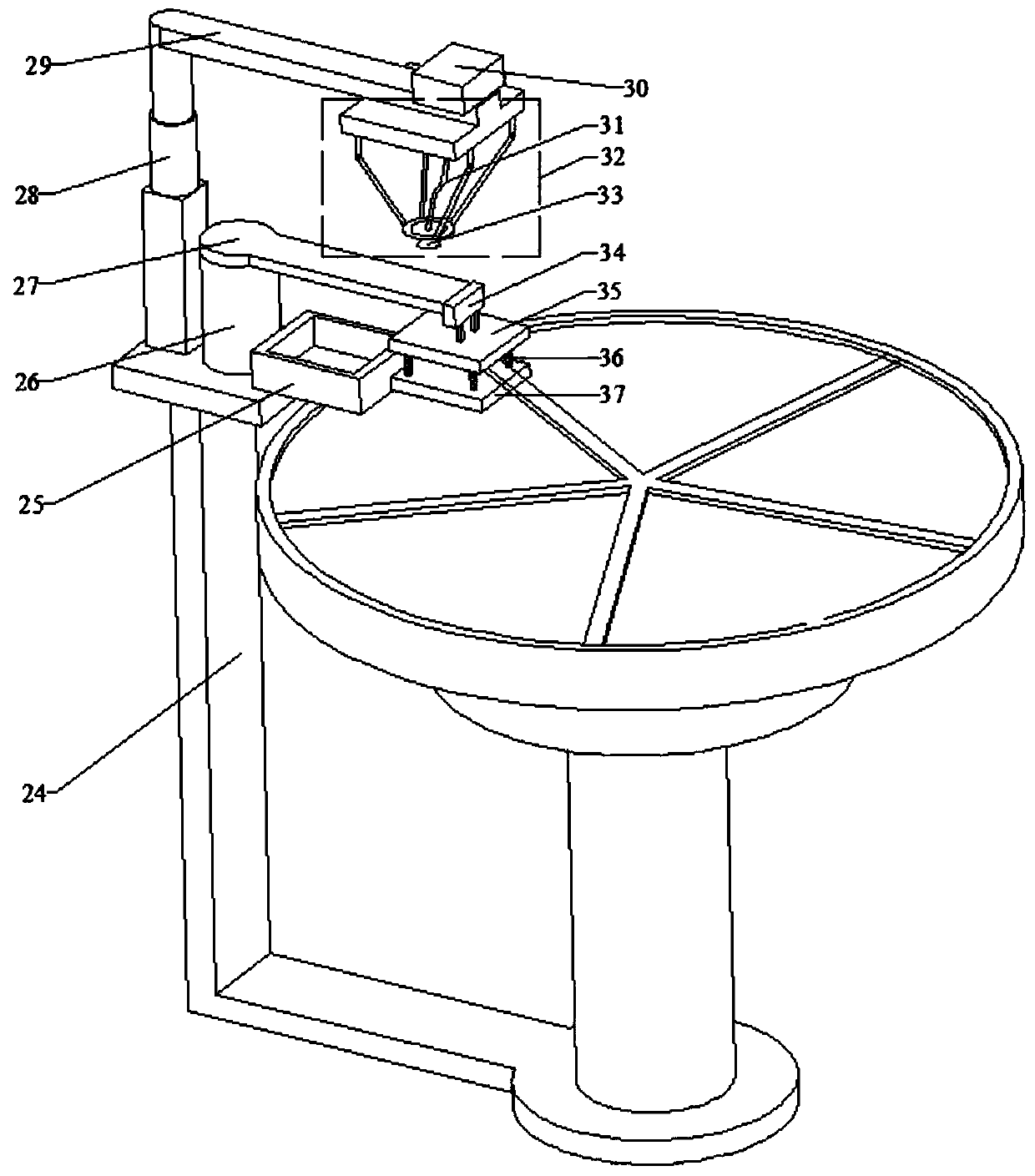

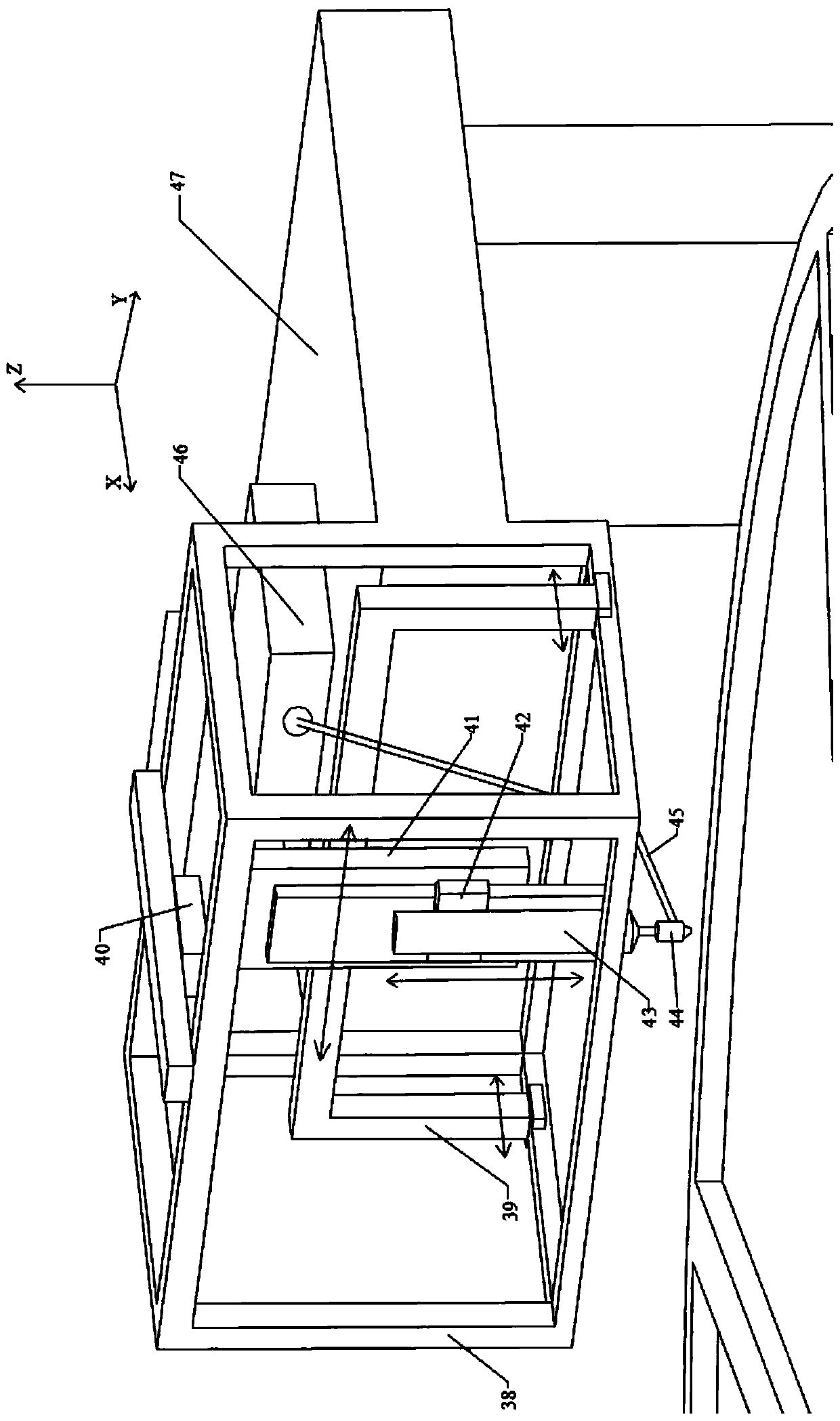

[0028] see Figure 1-5 , in an embodiment of the present invention, an automatic dismantling equipment for waste mobile phones suitable for assembly line operations, including a feeding system, a turntable type assembly line dismantling mechanism, and a feeding system;

[0029] The feeding system includes a logistics line belt conveyor 1, a first parallel manipulator 3, a first industrial camera 4, a first belt conveyor 5 and a first industrial robot 6, and the first belt conveyor 5 is arranged on the logistics line The middle part of the belt conveyor 1 and the two conveying directions are perpendicular to each other. The first parallel manipulator 3 is set on the end of the first belt conveyor 5 close to the logistics line belt conveyor 1, and the first industrial robot 6 is set on the first belt conveyor 5. Away from the end of the logistics line belt conveyor 1, the first industrial camera 4 is arranged on the side of the logistics line belt conveyor 1, and the first indus...

Embodiment 2

[0039] see Figure 4~5 The difference between this embodiment of the present invention and Embodiment 1 is that it also includes an inspection area 20, the inspection area 20 is set between the feeding system and the unloading system, an inspection component is arranged in the inspection area 20, and the inspection The components include the second industrial camera 16, the fourth industrial robot 18, the surplus material box II 19, the third belt conveyor 21 and the fifth industrial robot 22, the second industrial camera 16, the fourth industrial robot 18 and the surplus material box II 19 They are all set at the end of the third belt conveyor 21 close to the unloading system, and the fifth industrial robot 22 is set at the end close to the loading system.

[0040] After the waste mobile phone 2 completes the dismantling action in the three dismantling areas on the dismantling turntable, it is transported to the inspection area 20 by the second belt conveyor 15, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com