Multi-layer roller table steering machine and its tree-shaped roller table conveying system for dismantling industry

A technology of steering gear and steering motor, which is applied to mechanical conveyors, roller tables, conveyors, etc., and can solve the problems of cumbersome gear transmission, large roller table, and restraint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

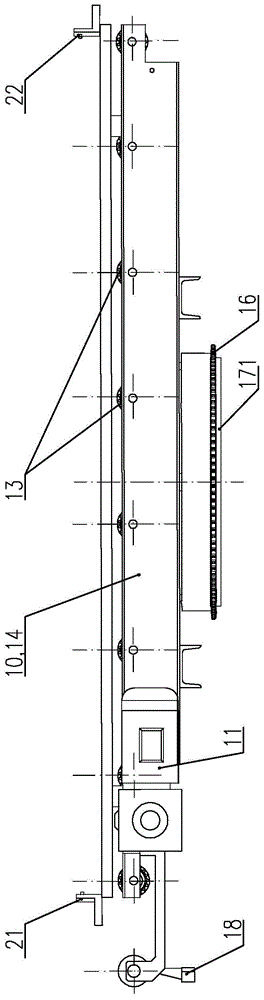

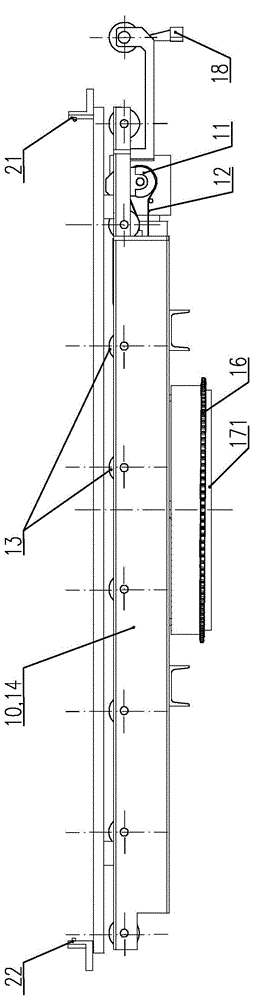

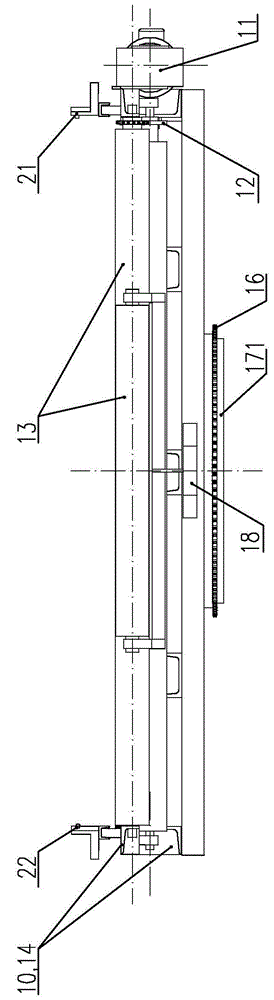

[0046] An embodiment of a multi-layer roller table steering machine 50 in the present invention includes a roller table section 10 and a base 30 .

[0047] Such as Figure 1-5 , which are structural schematic diagrams of different viewing angles of the embodiment of the roller table section 10 of the roller table steering machine of the present invention. The steering machine includes upper and lower roller table sections 10, the roller table section 10 includes a roller table motor 11, a transmission chain 12 and more than 2 rollers 13 driven by it, and the roller table section 10 includes a support roller table motor 11 With the two side plates 14 of the roller 13, the front bar 151, and the rear bar 152, the middle part of the roller table section of each layer is connected with a driven sprocket 16 and a steering bearing by bolts, etc. (not shown), and rotates through the steering bearing. It fits on the middle part of the bottom frame of each layer of the base 30, namely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com