Auxiliary dismantling device for differential dismantling

A differential and mounting technology, applied in metal processing, manipulators, metal processing equipment, etc., can solve the problems of high labor intensity, low efficiency, large damage, etc., to reduce secondary losses, reduce manual participation, and facilitate concentration. The effect of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

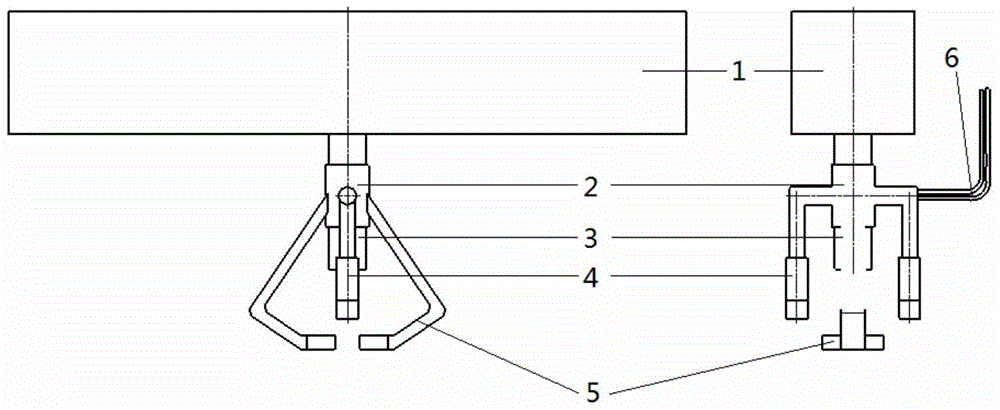

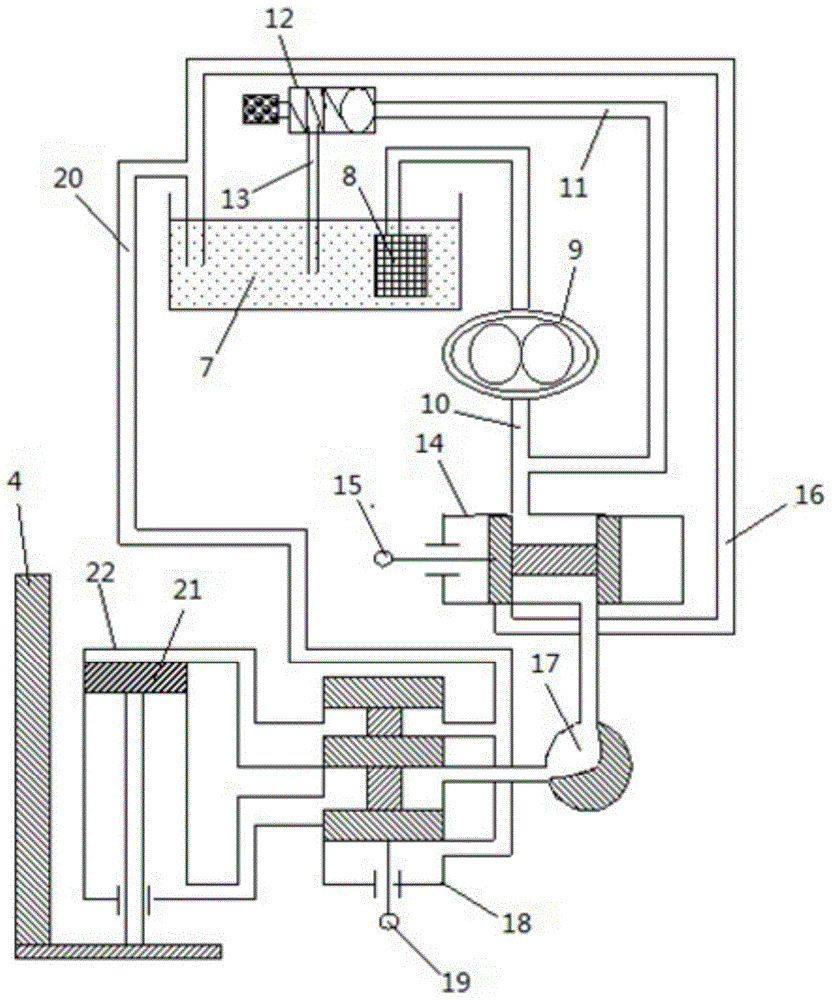

[0020] Such as figure 1 with figure 2 As shown, the auxiliary dismantling device for dismantling the differential according to the present invention includes a mechanical part and a hydraulic control part, and the specific structure and connection relationship are as follows:

[0021] The mechanical part includes a dismantling mechanism assembly frame 1, a lifting sleeve 2, a central shaft 3, a bolt dismantling wrench 4, a lifting mechanism mechanical claw 5 and a hydraulic circuit external pipeline 6. The hydraulic control part and the bolt dismantling wrench 4 are installed in the general assembly frame 1 of the dismantling mechanism, and one end of the central axis 3 is installed in the general assembly frame 1 of the dismantling mechanism, and one end protrudes outwards. The central shaft 3 is covered with the lifting sleeve 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com