Fastening body structure

A solid structure and fastening technology, applied to threaded fasteners, fixing devices, connecting components, etc., can solve problems such as difficult to achieve fastening purposes, achieve reliable and firm fastening, and easy disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

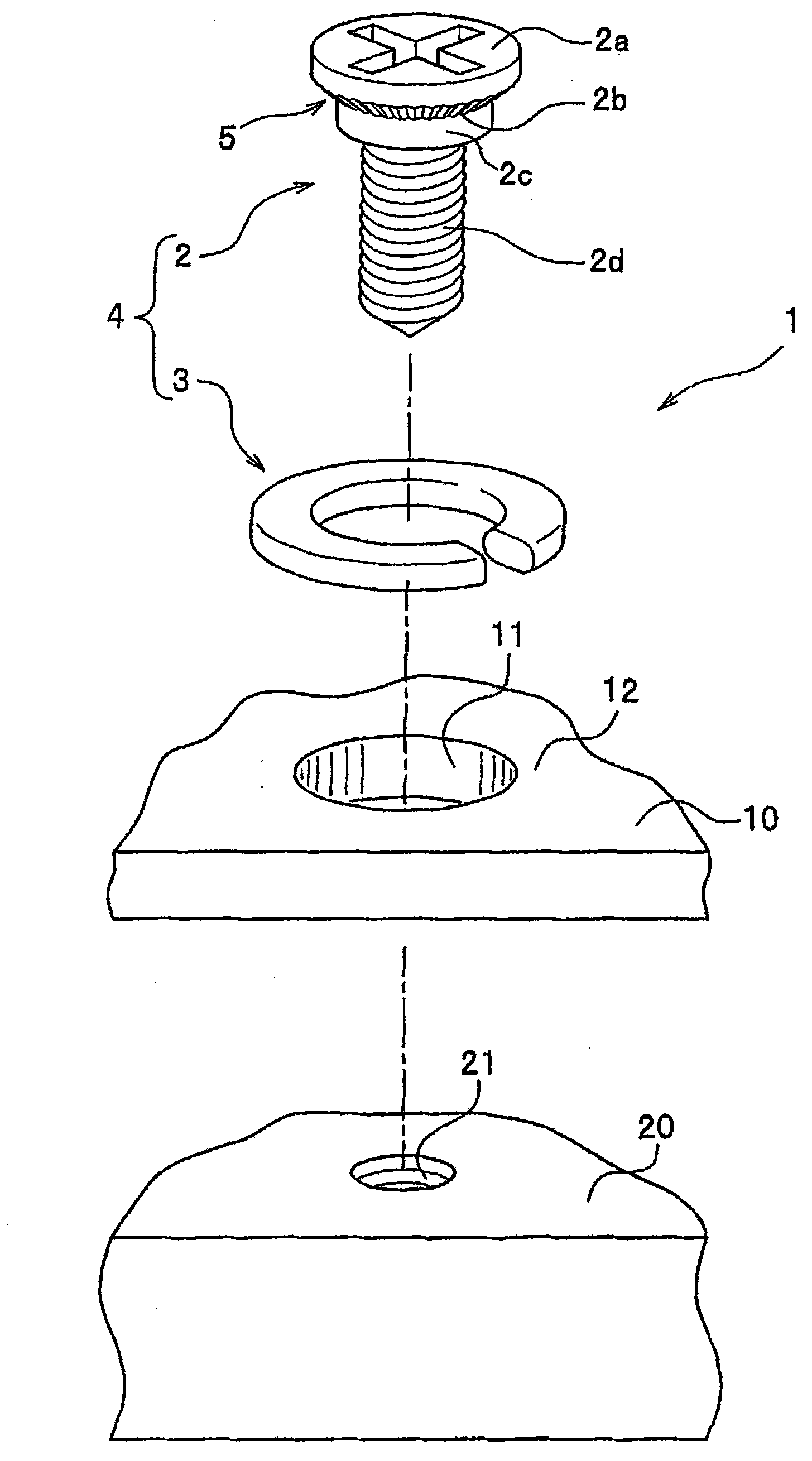

Embodiment 1

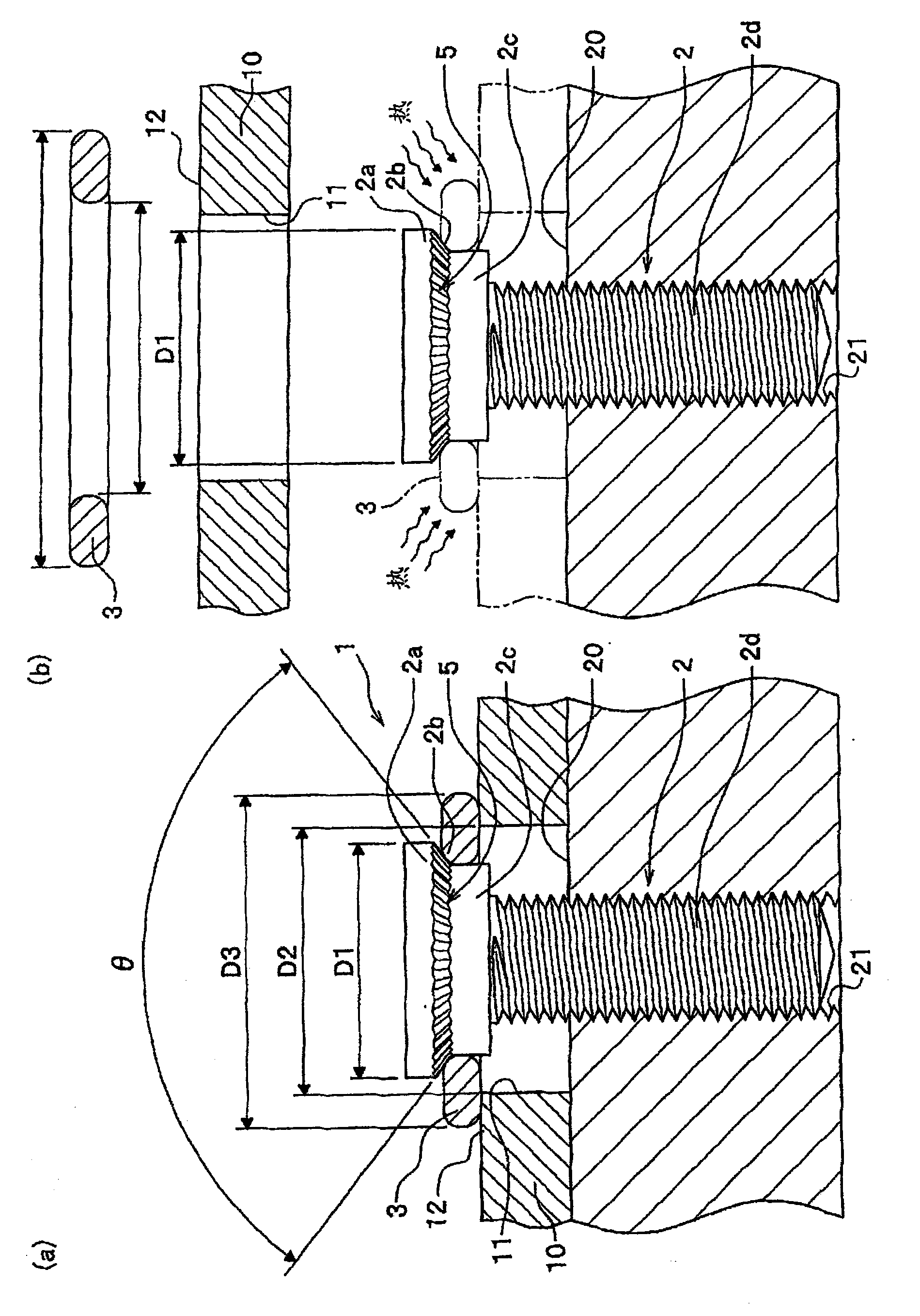

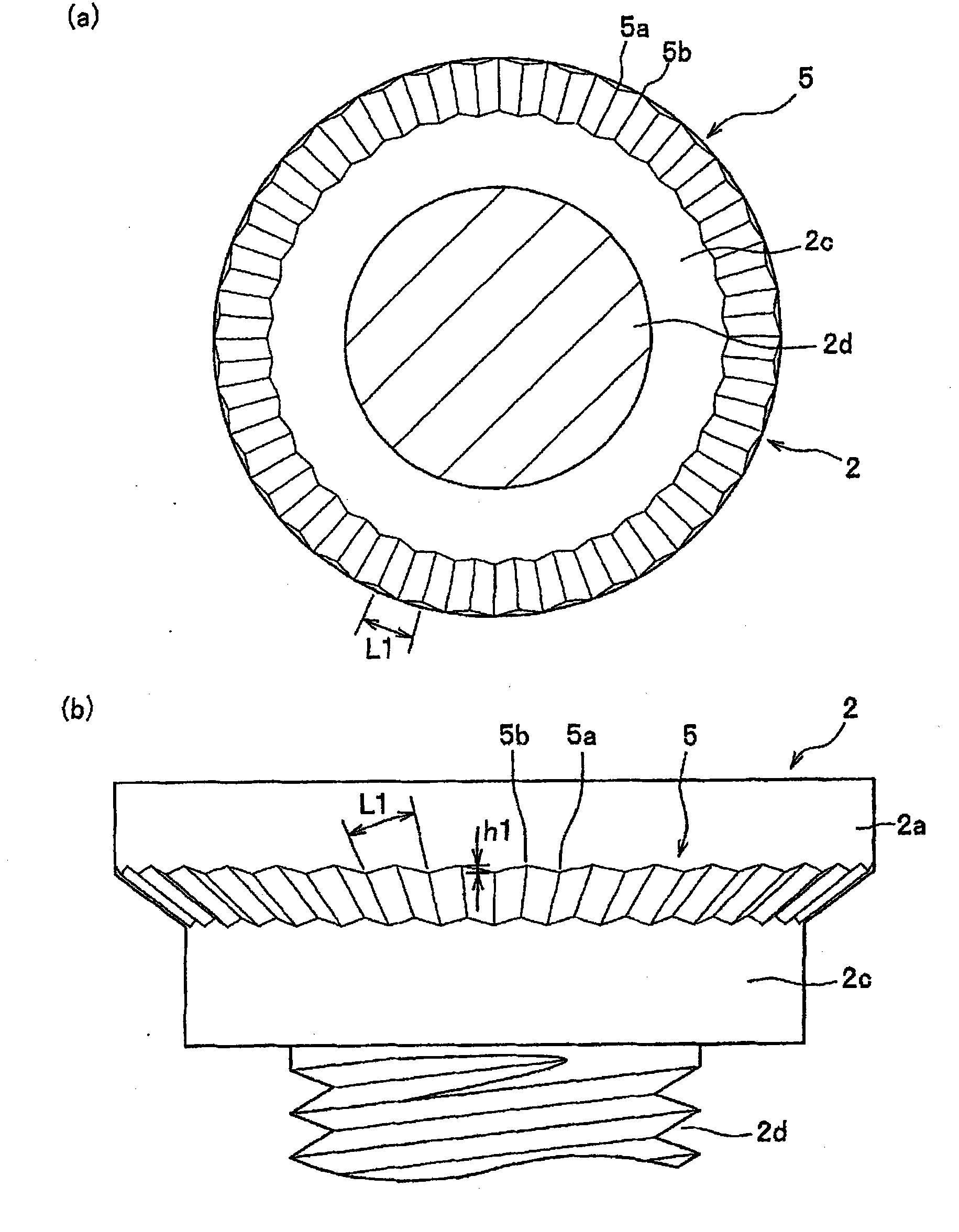

[0067] A steel plate with a length of 80 mm x a width of 30 mm x a thickness of 10 mm made of quenched steel equivalent to S45C was prepared in advance, and the following holes were drilled at 10 positions on the steel plate at equal intervals as a test piece. Apertures are provided on the upper part of this steel plate up to a depth of 4mm The countersink hole, and process the M4.0 internal thread at the lower part of the countersink hole. For module screw 2, such as image 3 As shown in (a) and (b), the concavo-convex part 5 is formed on the lower surface of the head part 2a with a length of 6.5 mm and an inclination angle of 20 degrees (sunk head angle 140 degrees) by knurling. At this time, the number of convex portions 5 a in the circumferential direction on the head lower surface of the module screw 2 was 36, and the height h1 of the convex portions 5 a was 0.1 mm. In addition, the diameter of the step part (shank part) of the module screw 2 is 5 mm, and the module sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com