Automatic disassembling line for waste lead-acid batteries

A lead-acid battery and battery technology, applied in the direction of lead-acid battery, battery recycling, waste collector recycling, etc., can solve the problems of small environmental pollution, large human injury, and low dismantling cost, so as to improve recovery rate and remove large damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

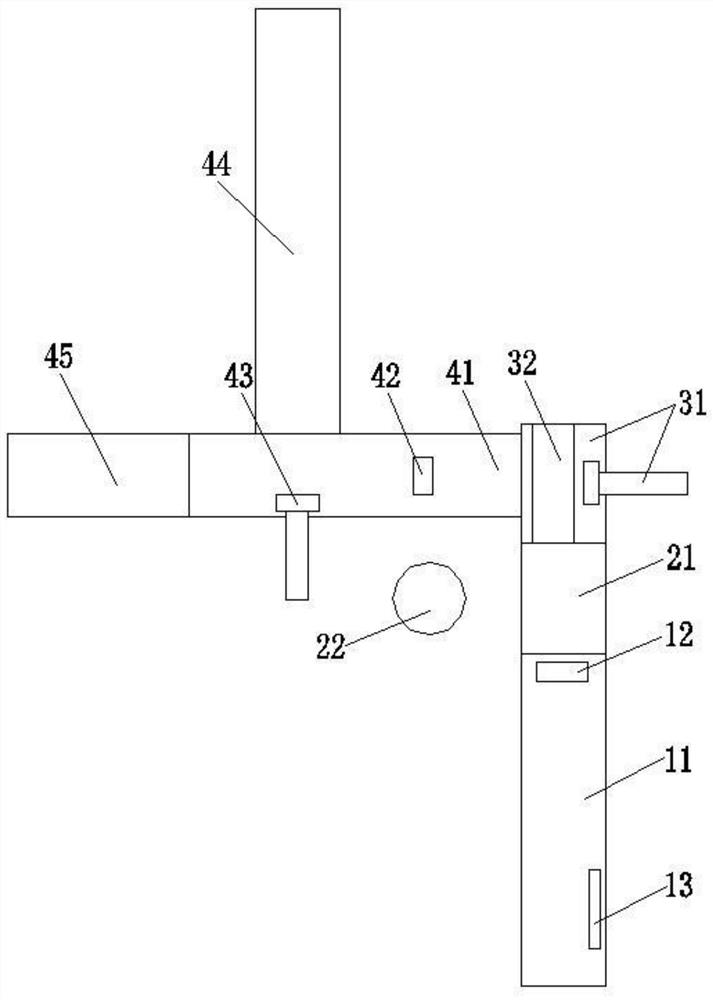

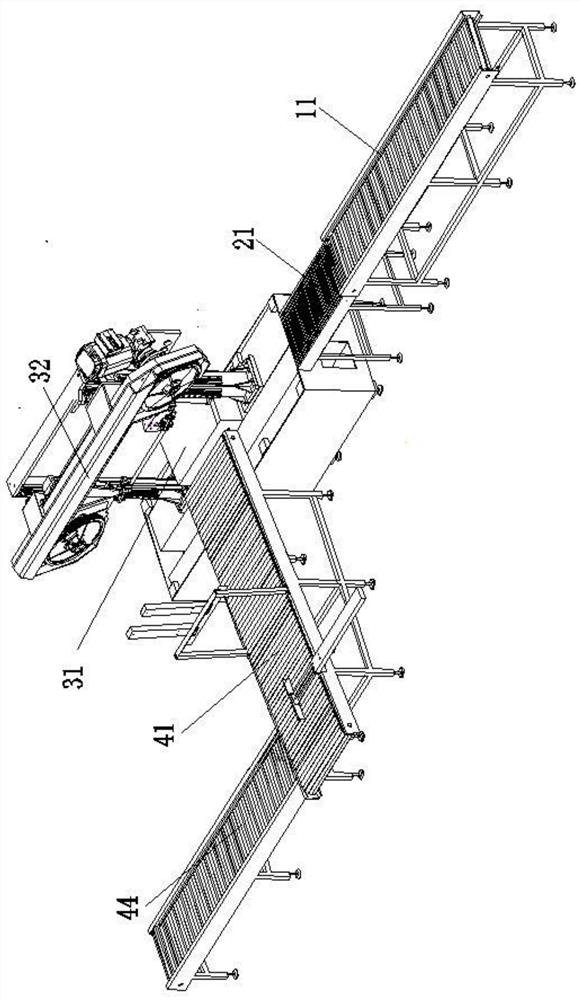

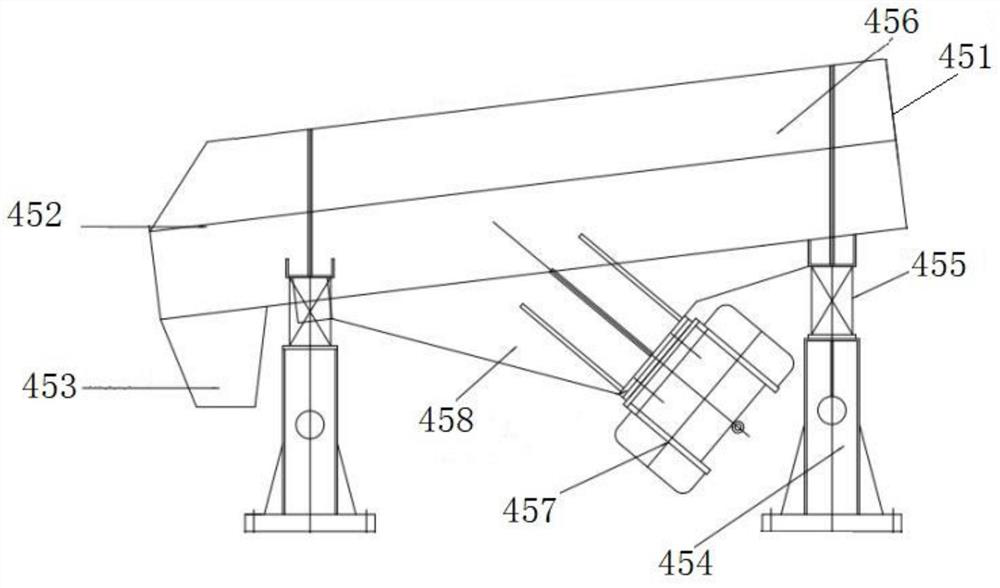

[0036] see Figure 1 to Figure 3 , as shown in the illustration, an automatic dismantling line for waste lead-acid batteries. The battery to be disassembled includes a battery body and a battery cover. The battery body includes a battery case and a battery cell inside the battery case. The battery cover is connected to At the opening of the battery case, the automatic dismantling line for waste lead-acid batteries includes a battery identification unit, a battery handling unit, a battery cutting unit, and a battery sorting unit.

[0037]The battery identification unit includes a first transmission line 11 and a battery type identification device 12. The first transmission line 11 accepts and transports the batteries sent from the upstream section, and the battery type identification device 12 identifies the battery type of the first transmission line 11. The battery model is sent to the battery handling unit and the battery cutting unit;

[0038] The battery handling unit inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com