Method for forming test patterns

A technology for testing graphics and graphics, which is applied to the photo-engraving process of the pattern surface, the originals and instruments for opto-mechanical processing, etc., which can solve the problem that the product yield needs to be improved, and achieve a rich variety and quantity with high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

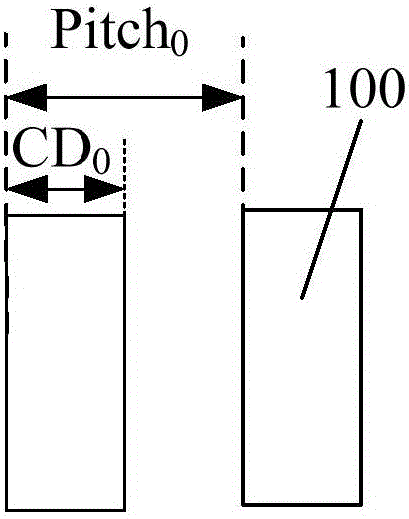

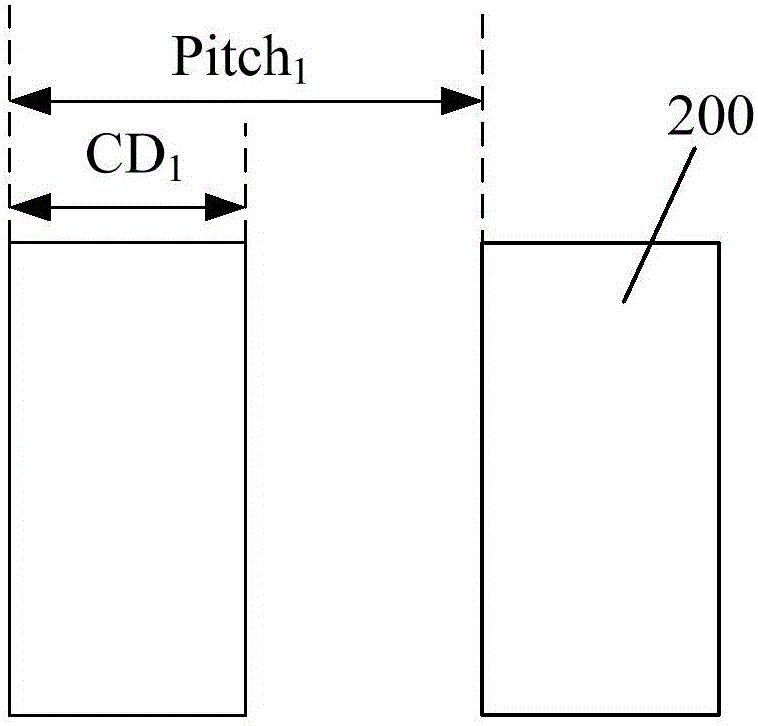

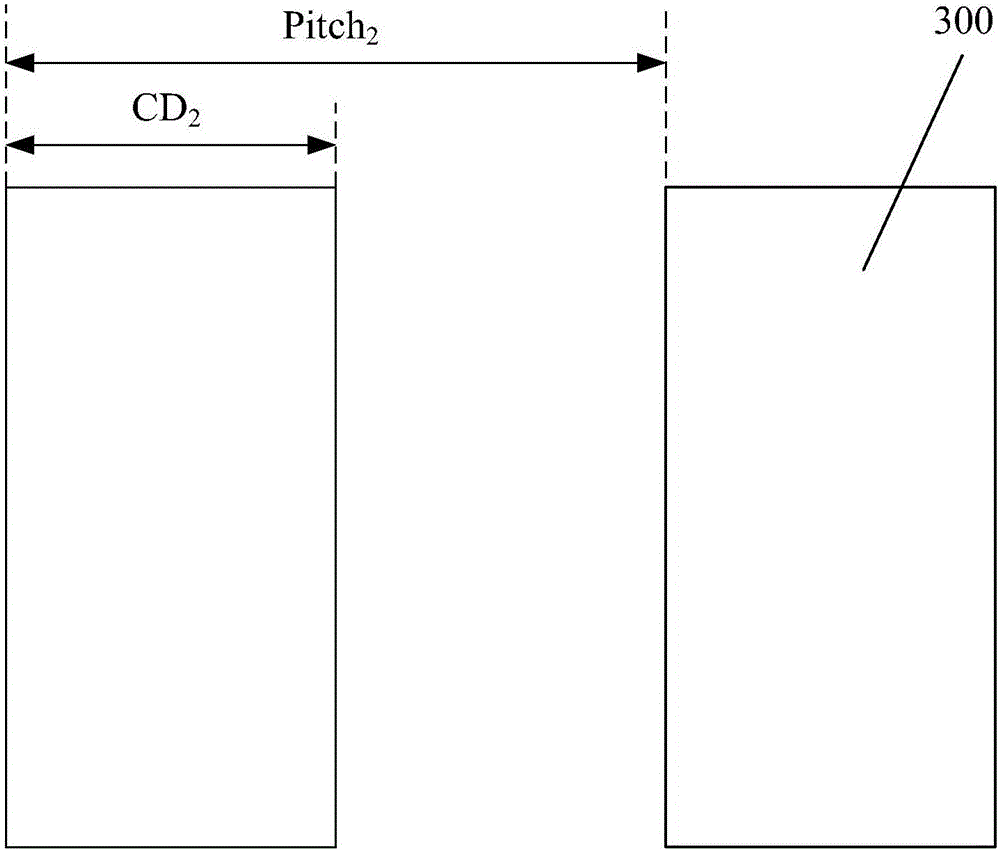

[0022] As mentioned in the background art, the yield rate of the products manufactured by adopting the dual patterning technology in the prior art still needs to be improved.

[0023] After research, it is found that when the prior art performs various inspections on the first design pattern and the second design pattern obtained by dismantling, it is actually compared with the test pattern in the test pattern library (library), that is to say, the test The type and quantity of test patterns in the pattern library will affect the detection results. For example, the test patterns in the test pattern library have fewer types or fewer quantities. In fact, the first design graphic and the second design graphic may not be the optimal dismantling graphic, and when the gap between the first design graphic and the second design graphic and the optimal dismantling graphic is large, it will seriously affect the manufacturing process. product yield.

[0024] Further study provides a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com