Stainless steel metal recovery device

A recovery device, stainless steel technology, applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of ecological colony formation, stainless steel rice tank damage, large space occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

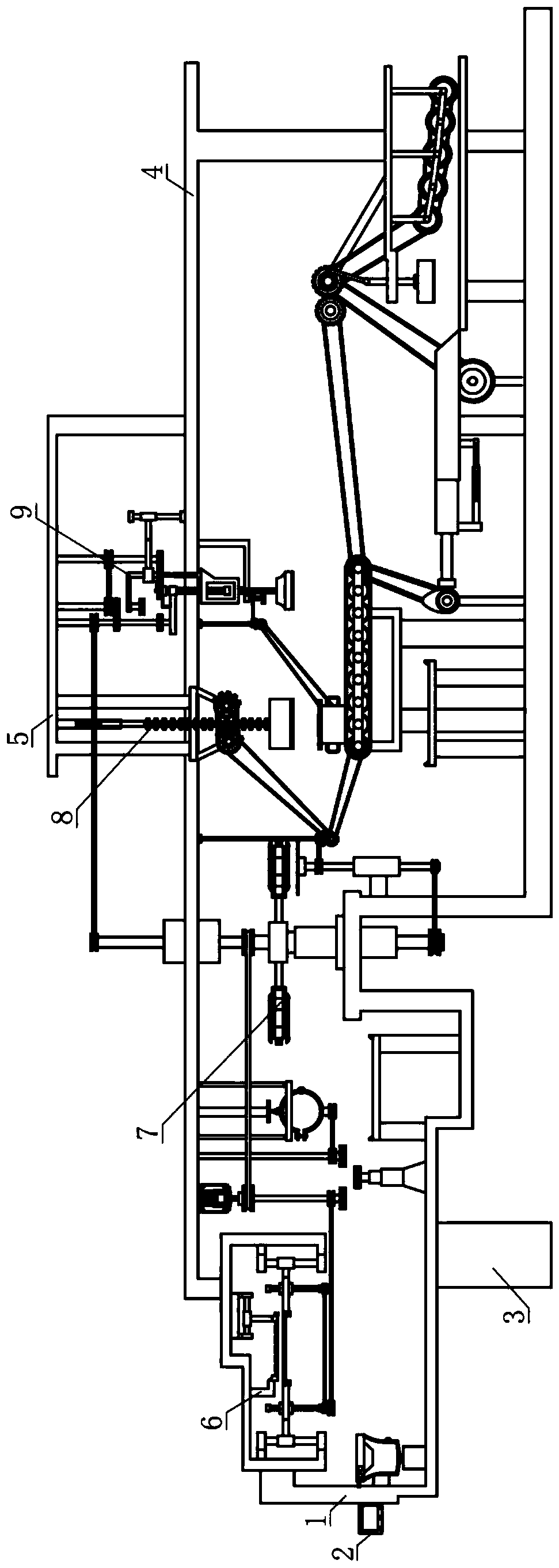

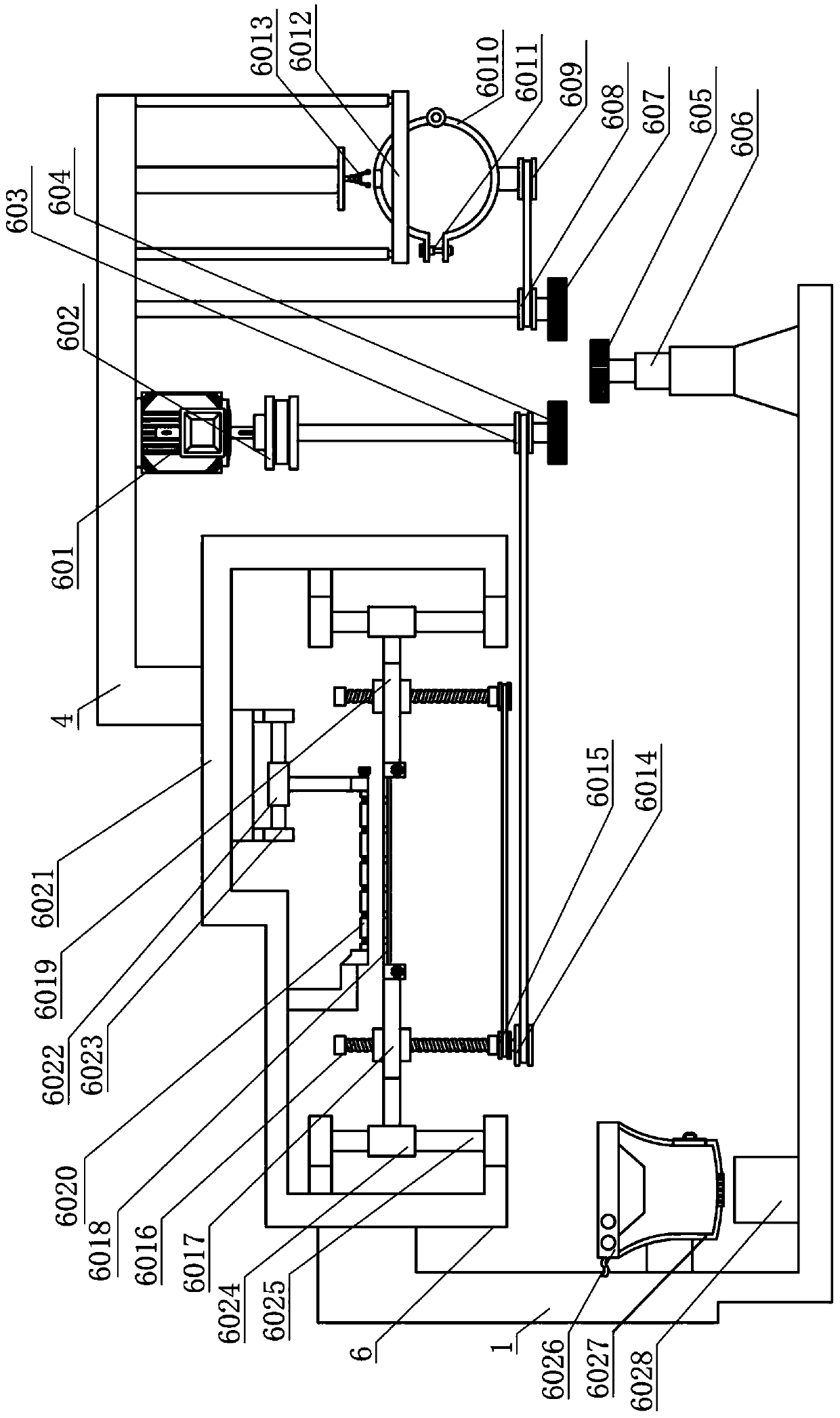

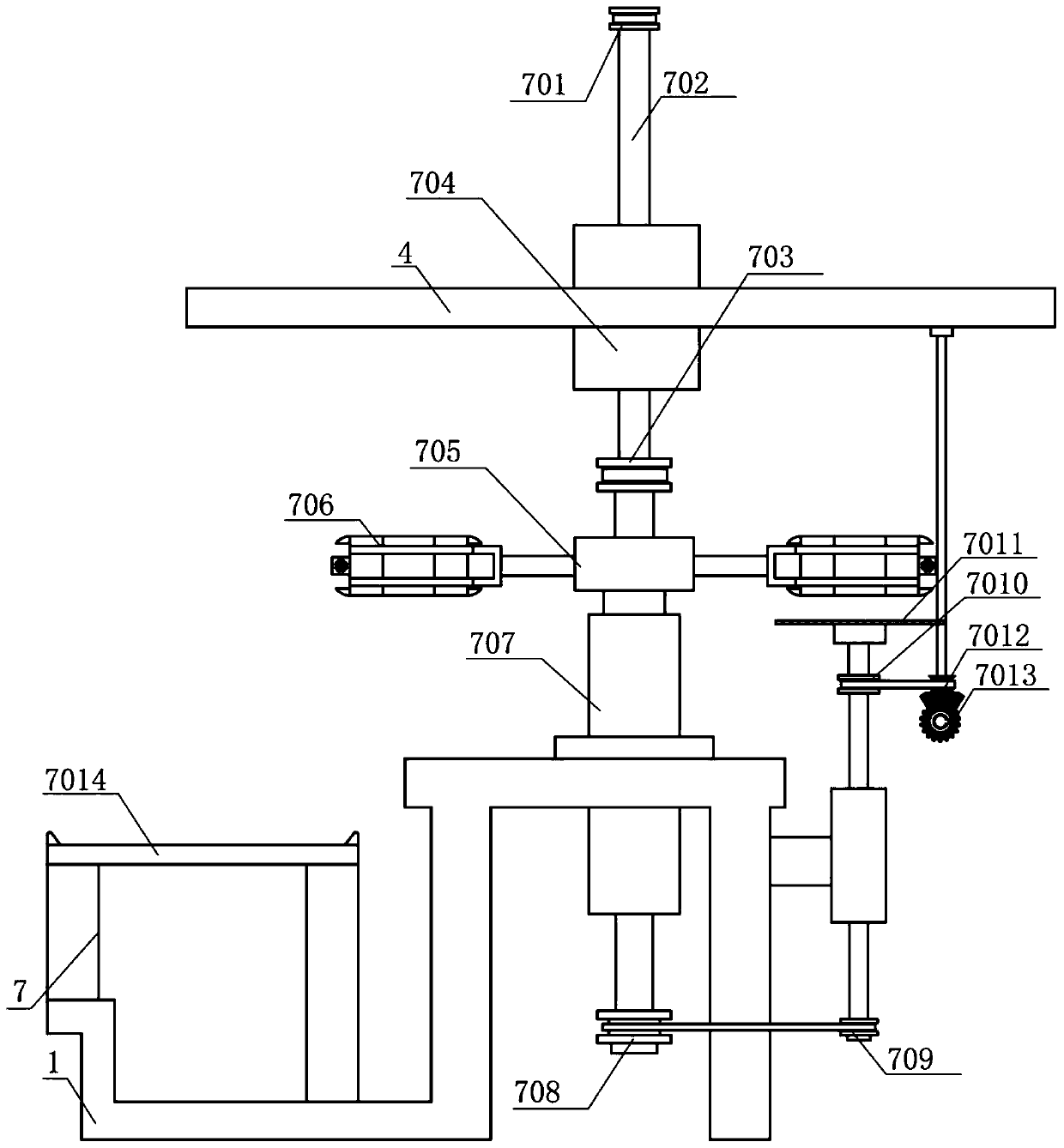

[0028] A stainless steel metal recovery device, comprising a bottom connection frame 1, an operation control panel 2, a supporting foot 3, a top connection frame 4, a middle top fixing frame 5, a handle disassembly mechanism 6, a bottom surface cutting mechanism 7, and a curling removal mechanism 8 and the film separation mechanism 9; the middle and lower part of the left end of the bottom connection frame 1 is provided with a running control panel 2; the bottom left side of the bottom connection frame 1 is connected with the support foot 3; the top right side of the bottom connection frame 1 is connected with the top connection frame 4 Connection; the left side of the bottom connection frame 1 is provided with a handle disassembly mechanism 6, and the top right middle part of the handle disassembly mechanism 6 is connected with the top connection frame 4; the left middle part of the bottom connection frame 1 is provided with a bottom surface cutting mechanism 7, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com